Potato slicing equipment for potato chip production

A slicing and potato technology, applied in metal processing and other directions, can solve the problems of easy cutting of hands, large workload of potato slicing, etc., and achieve the effect of reducing the workload of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

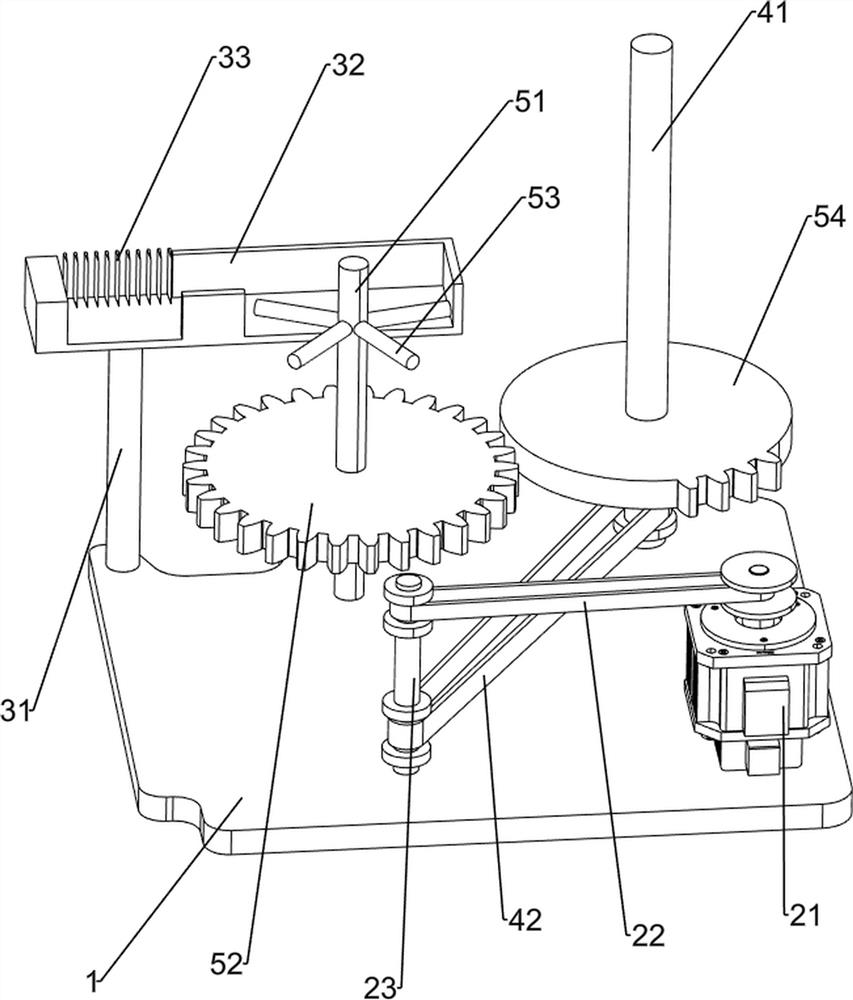

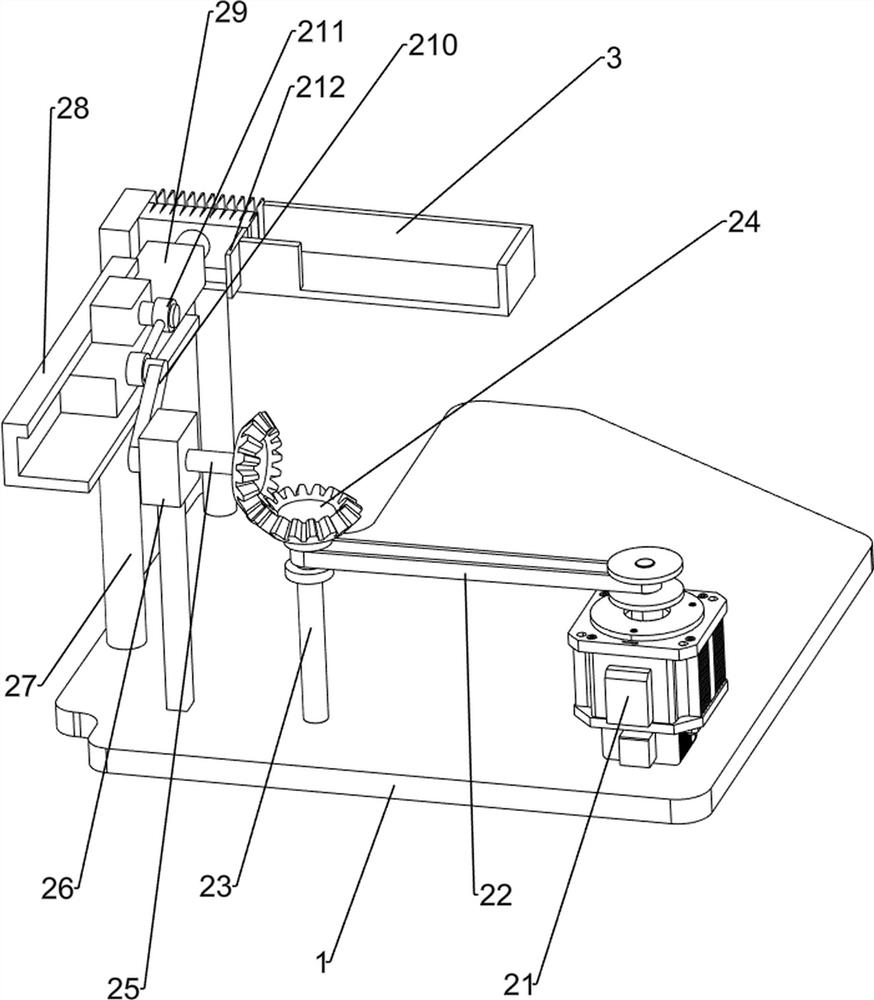

[0023] A kind of potato slicing equipment for potato chip production, such as Figure 1-4 As shown, it includes a base 1, a pushing mechanism 2 and a slicing mechanism 3, and the pushing mechanism 2 and the slicing mechanism 3 are installed on the base 1 respectively.

[0024] Propelling mechanism 2 comprises servo motor 21, first pulley group 22, first rotating shaft 23, bevel gear group 24, second rotating shaft 25, first pillar 26, second pillar 27, slide rail 28, slide block 29, the first Swing lever 210, the second swing lever 211 and the first baffle plate 212, a servo motor 21 is installed on the right front side of the top of the base 1, and a first rotating shaft 23 is rotationally connected to the front side of the top of the base 1, and the first rotating shaft 23 is connected to the servo motor 21. A first pulley set 22 is connected between the output shafts, a first support 26 is connected to the left front side of the top of the base 1, a second rotating shaft 25...

Embodiment 2

[0028] On the basis of Example 1, such as figure 1 with image 3 As shown, it also includes a blanking mechanism 4. The blanking mechanism 4 includes a third rotating shaft 41, a second pulley set 42, a second baffle plate 43, a support plate 44, a blanking pipe 45 and a blanking hopper 46, and the top of the base 1 The right rear side is rotationally connected with a third shaft 41, a second pulley set 42 is connected between the third shaft 41 and the first shaft 23, a support plate 44 is connected to the rear side of the top of the base 1, and a blanking plate 44 is connected to the top of the support plate 44. Pipe 45, the top of the feeding pipe 45 is connected with a feeding hopper 46, and the top of the third rotating shaft 41 is connected with two second baffles 43, and the second baffles 43 are slidingly fitted with the feeding pipe 45.

[0029] A large amount of potatoes can be poured into the lower hopper 46, and the potatoes then enter the lower tube 45, and the p...

Embodiment 3

[0031] On the basis of Example 2, such as figure 1 with Figure 4 As shown, a feeding mechanism 5 is also included. The feeding mechanism 5 includes a fourth rotating shaft 51, a spur gear 52, a feeding rod 53 and a missing gear 54. The rear side of the top of the base 1 is rotationally connected with a fourth rotating shaft 51. Located on the left side of the third rotating shaft 41, the fourth rotating shaft 51 bottom is connected with a spur gear 52, the fourth rotating shaft 51 top is connected with a plurality of feeding rods 53, the bottom of the third rotating shaft 41 is connected with a missing gear 54, and the missing gear 54 is connected with the straight gear. Gear 52 cooperates.

[0032] Potatoes fall into the feeding rod 53 thereupon, and the third rotating shaft 41 rotates to drive the missing gear 54 to rotate. The fourth rotating shaft 51 rotates, and the fourth rotating shaft 51 rotates to drive the feed rod 53 to rotate, and the rotation of the feed rod 53...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com