Automatic welding platform for furniture steel pipes

An automatic welding and steel pipe technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reduced practicability, single size of steel pipe welding, low welding efficiency, etc., and achieves simple and convenient operation. Satisfy the effect of welding work and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the patent solution of the present invention, the invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

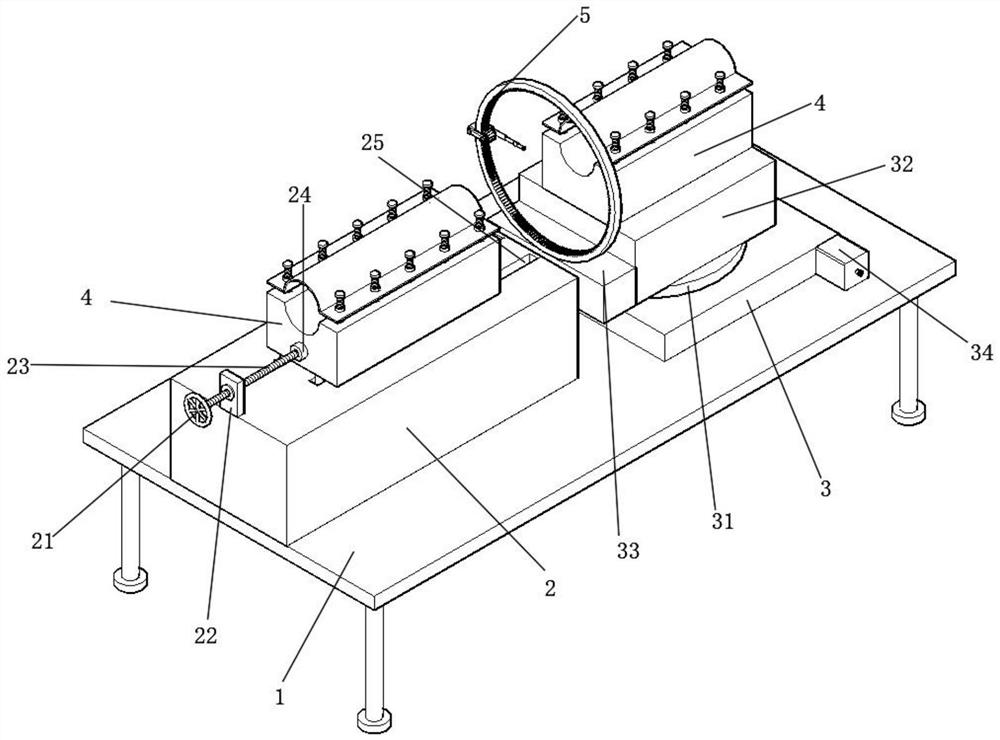

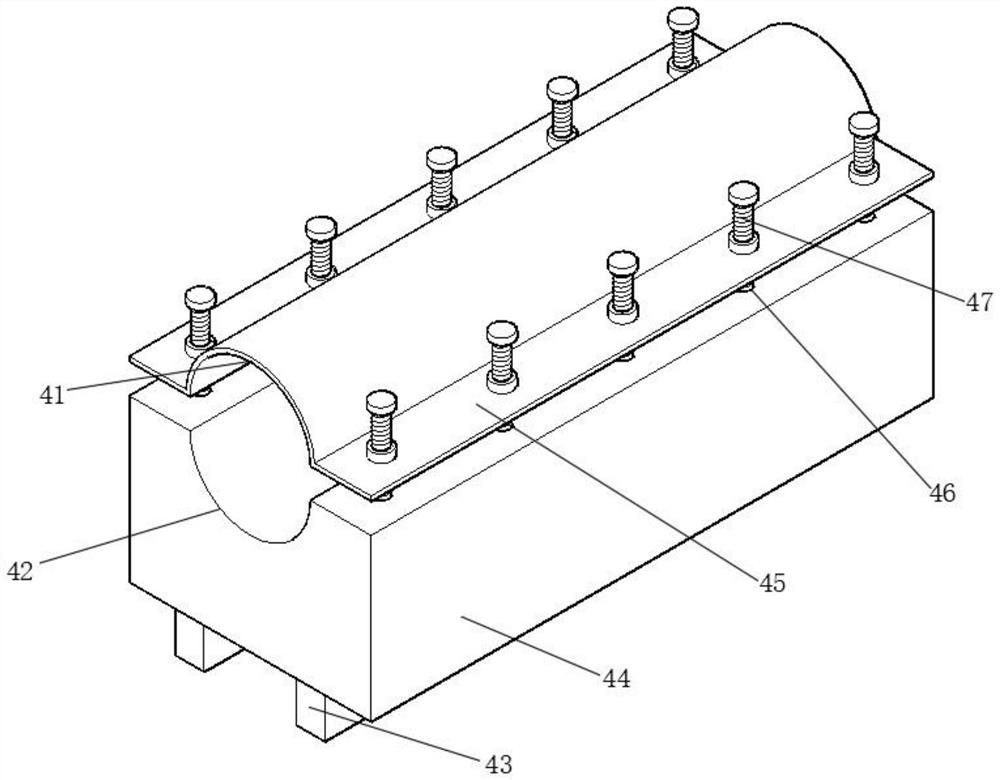

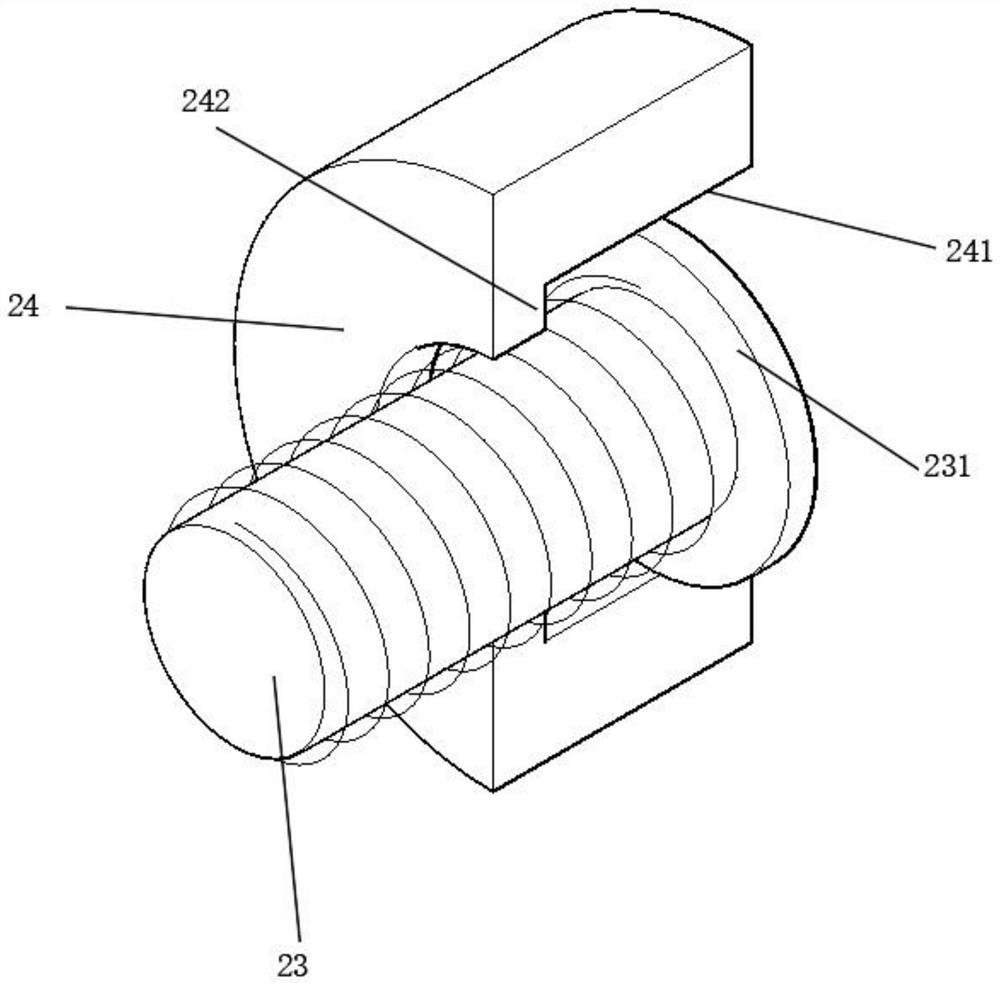

[0019] Such as Figure 1-4 As shown, an automatic welding platform for furniture steel pipes includes a platform 1, and the top of the platform 1 is fixed with a first fixed plate 2 and a rotary table 3 in parallel. The side of the rotary table 3 is provided with a first motor 34, which rotates The top of the rotating disk 31 on the top of the platform 3 is fixedly provided with a second fixed plate 32 whose top is the same height as the first fixed plate 2, and the top of the first fixed plate 2 is slidably connected with a clamp 4, and the top of the second fixed plate 32 is fixed A clamp 4 is provided, and a connecting plate 33 is provided on a side surface of the second fixing plate 32 close to the first fixing plate 2 , and a welding dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com