Fastener driving tool

A technology for driving tools and fasteners, used in nailing tools, manufacturing tools, nailing tools, etc. It can improve the ease of aiming, stabilize the driving posture, and reduce the frequency of occurrence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Embodiments of the present invention will be described with reference to the drawings.

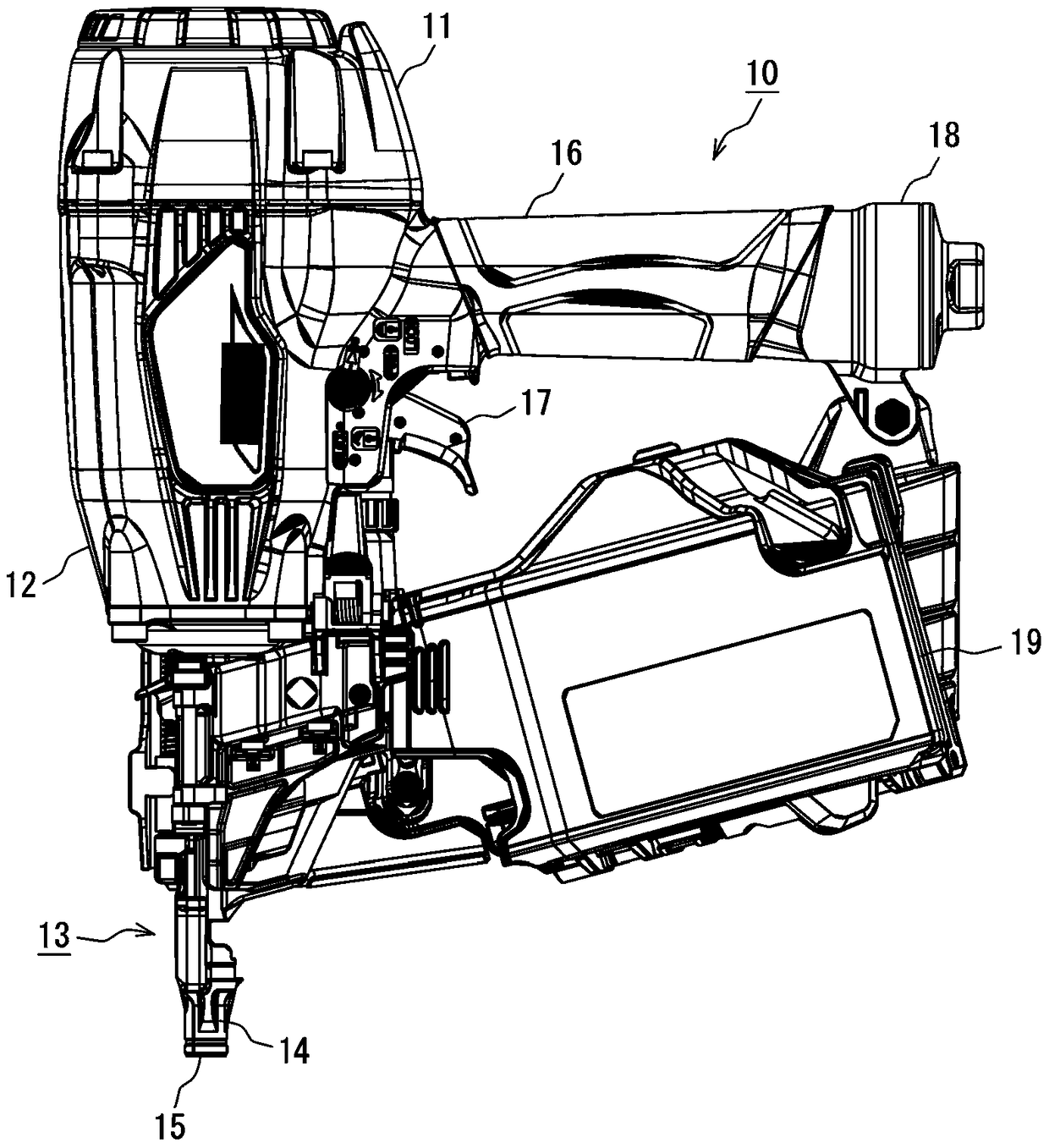

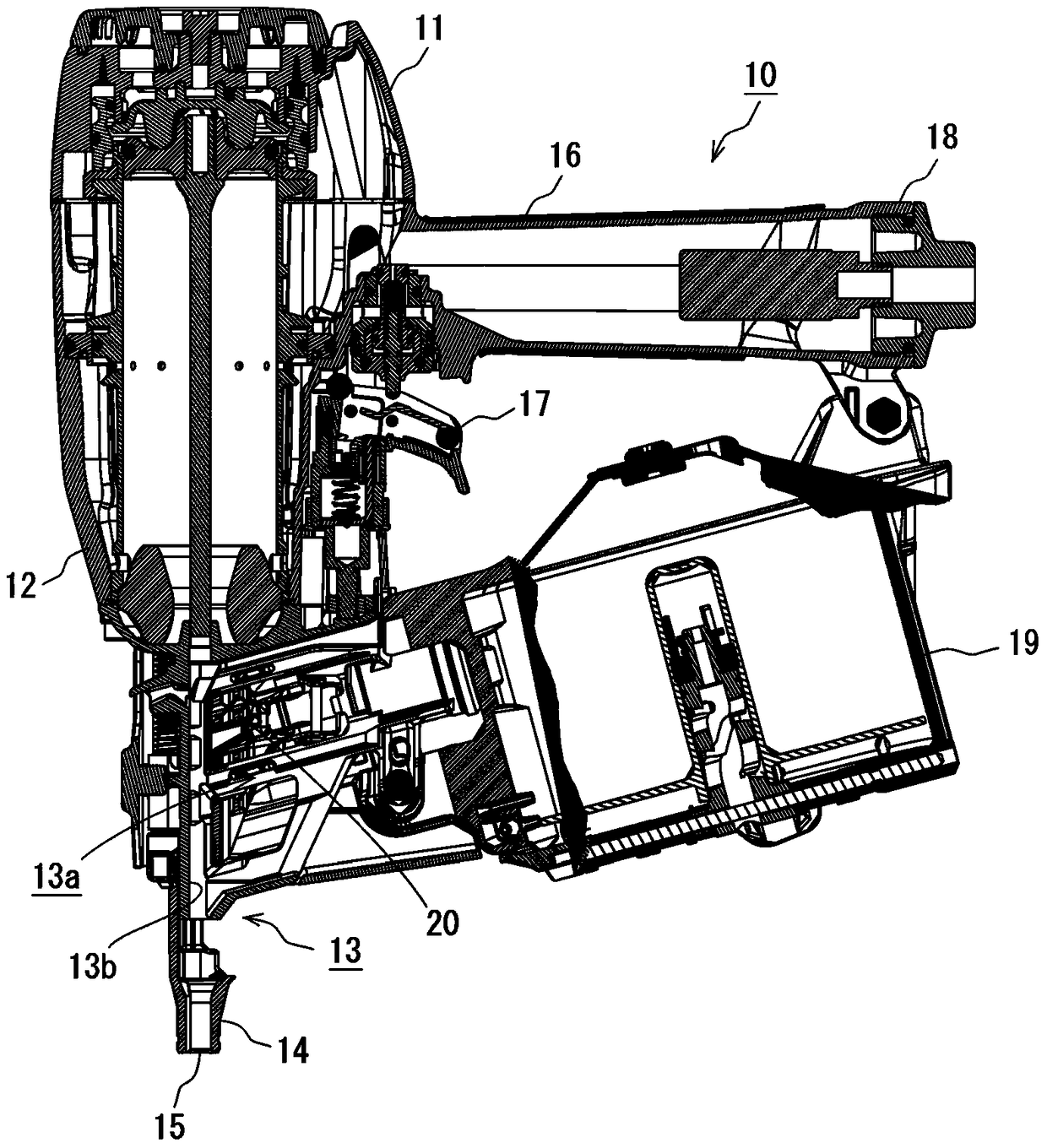

[0091] The fastener driving tool 10 of the present embodiment is an air pressure driving tool that utilizes compressed air to drive the fastener 41, such as figure 1 As shown, there are: a tool main body 11 having a nose portion 13 and a nail magazine 19 connected to the tool body 11 on the side of the nose portion 13 .

[0092] In the tool main body 11, the main body case 12 and the mobile phone case 16 are connected at substantially right angles and constituted. A striking cylinder is disposed inside the main body casing 12 , and a striking piston is slidably accommodated in the striking cylinder. The driver 21 for striking the fastener 41 is arranged in combination with the lower surface of the striking piston, and the fastener 41 can be driven in by the driver 21 when the striking piston moves.

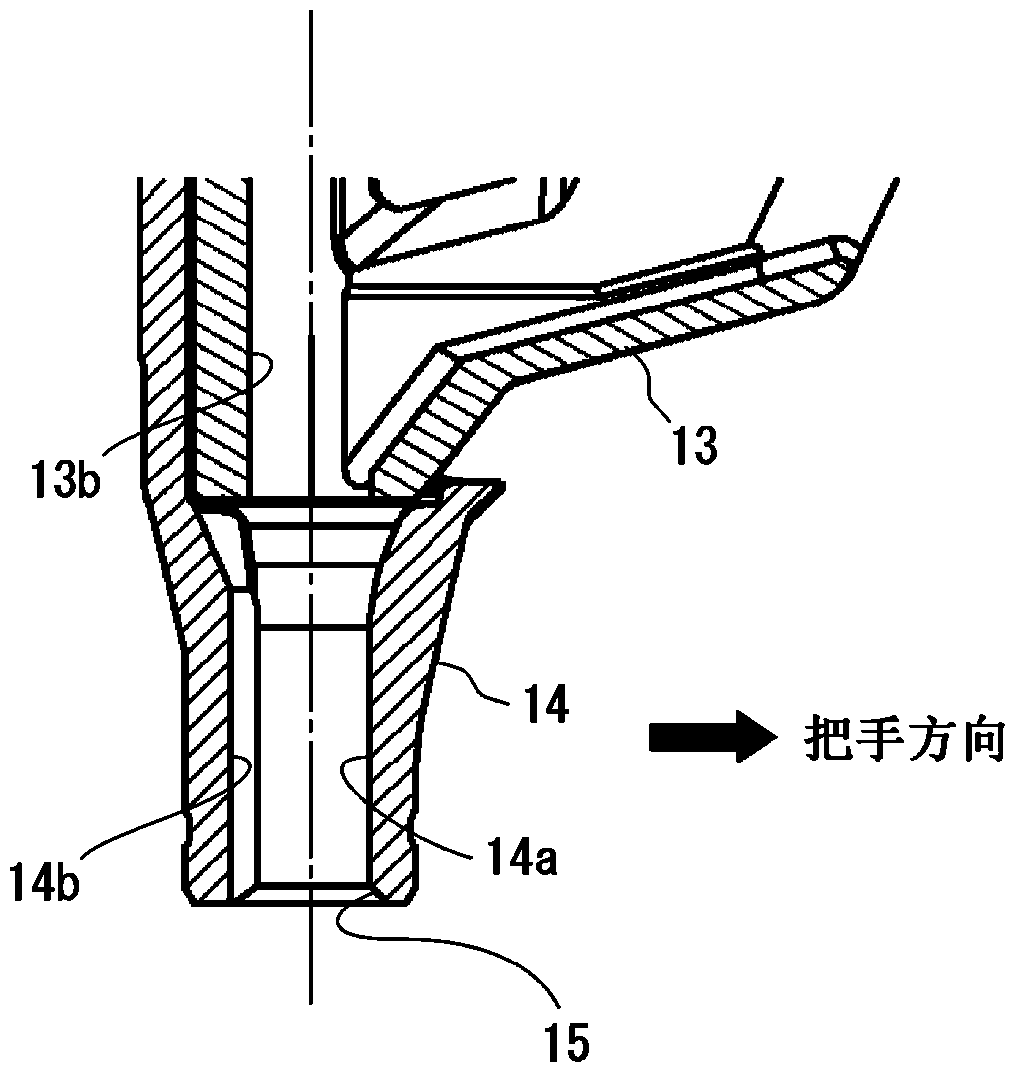

[0093] A handpiece 13 for injecting fasteners 41 is provided at the lower front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com