Lens drive device, automatic focusing camera and mobile terminal with camera

A lens driving device and lens technology, which is applied to cameras, focusing devices, electromechanical devices, etc., can solve problems such as easy deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

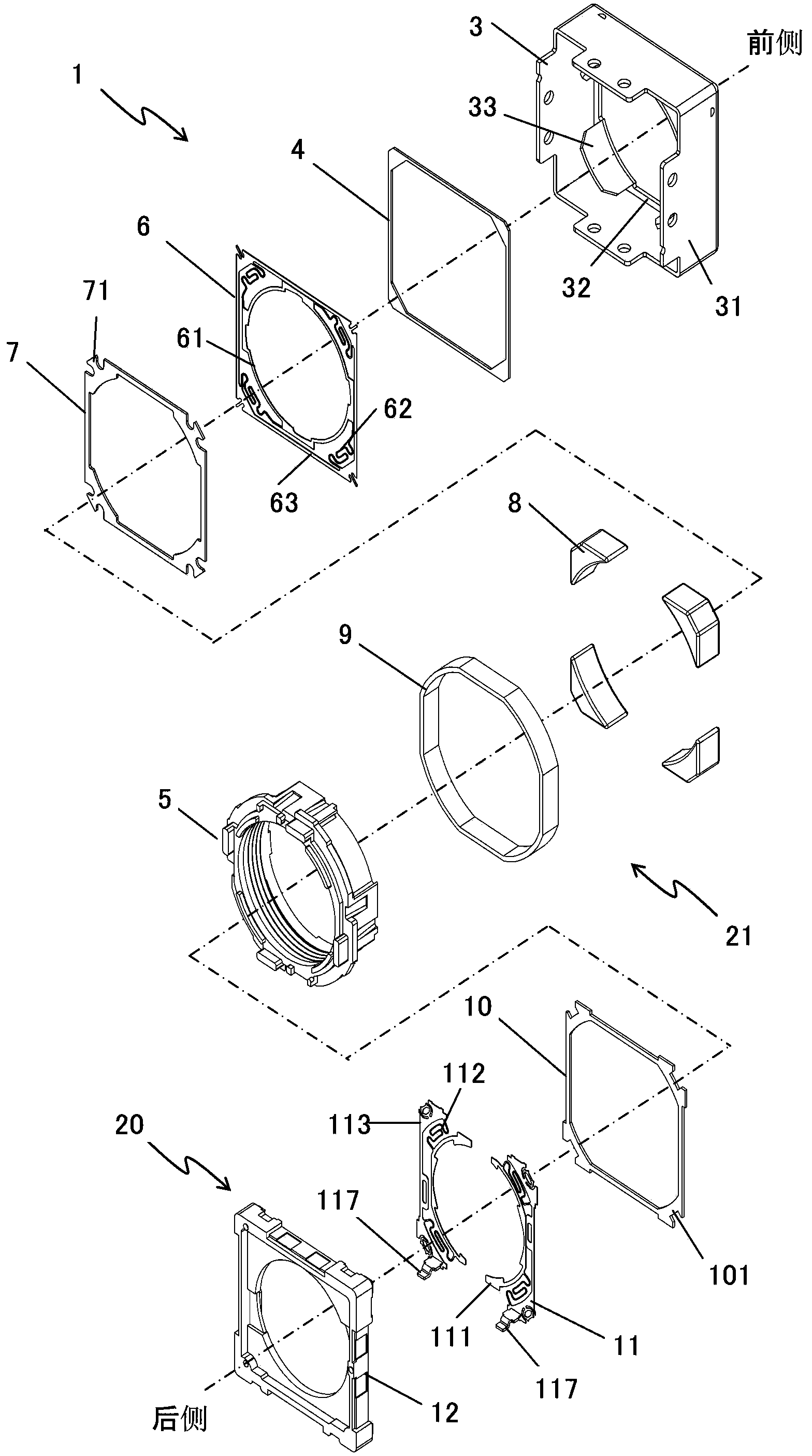

[0050] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0051] The lens driving device 1 in this embodiment is a lens driving device used in an auto-focus camera device incorporated in a camera-equipped mobile terminal device typified by a cellular phone and a smart phone.

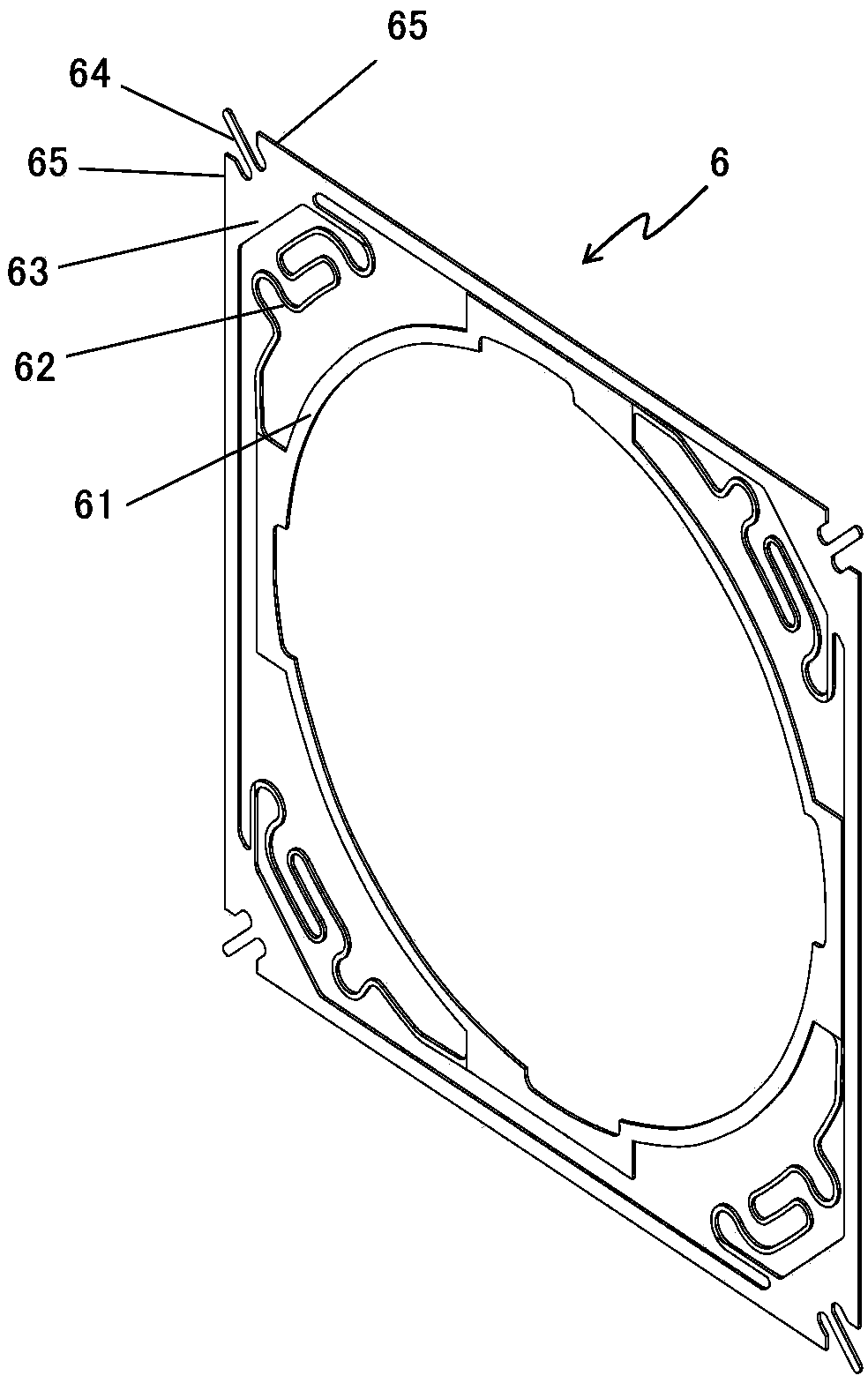

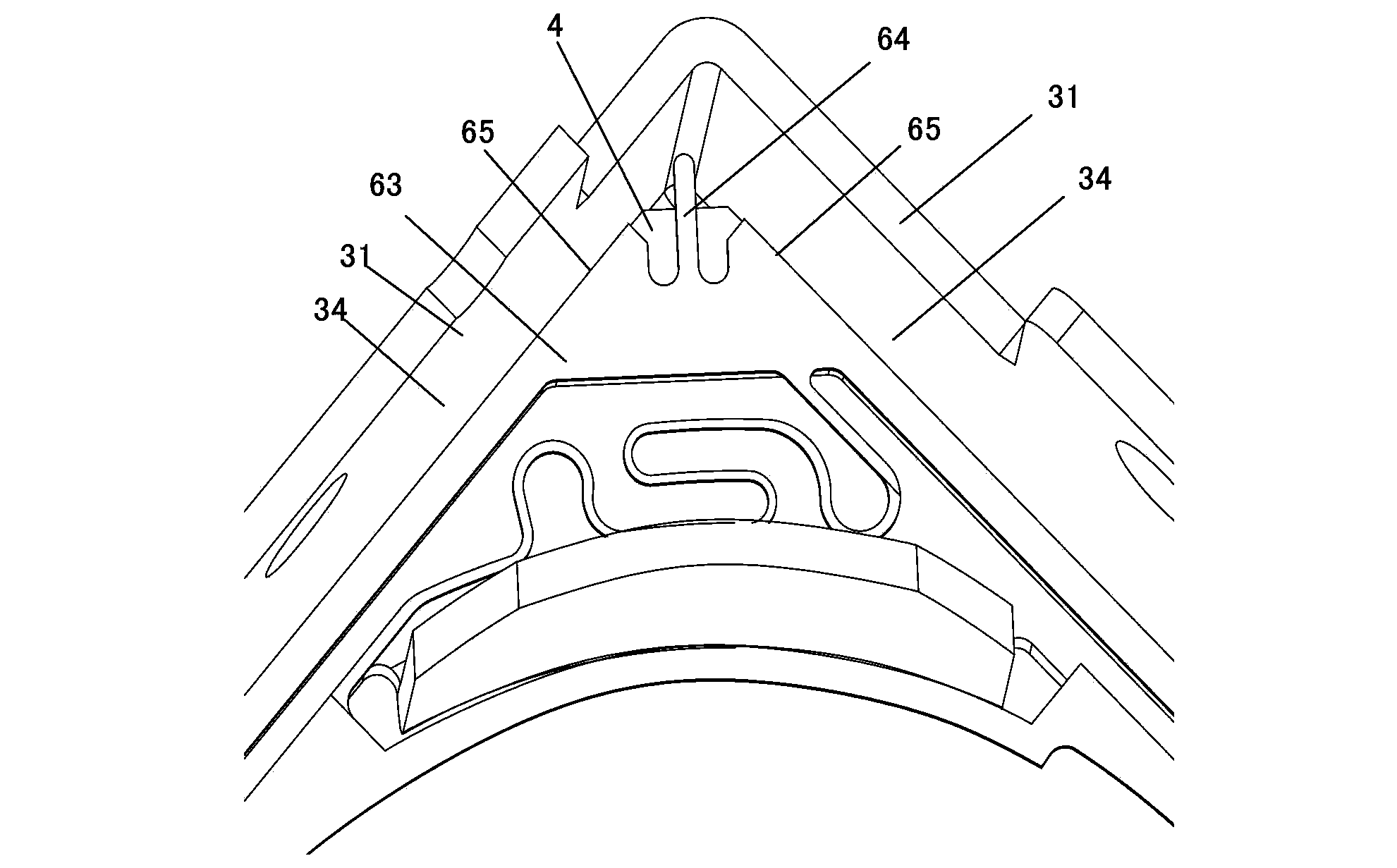

[0052] This lens driving device 1 such as figure 1 As shown, a lens support body 5 , a fixing part 20 , a drive mechanism 21 , and leaf spring members 6 and 11 are included. The lens support body 5 supports a lens (not shown) movably in the direction of its optical axis. The fixing part 20 is disposed on the outer peripheral side of the lens support body 5. The drive mechanism 21 moves the lens support body 5 in the direction of the optical axis. The leaf spring members 6, 11 have inner parts 61, 111 fixed to the lens support body 5 , the outer part 63, 113 fixed on the fixing part 20, and the plurality of arm parts 62, 112 connecting the inner part 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com