High-precision automatic feeding and cutting mechanism

An automatic feeding and high-precision technology, which is applied in the field of stamping strip processing, can solve the problems of increasing the strength of operators, time-consuming and laborious strip inspection, and poor human-computer interaction effects, etc., and achieves simple structure, low manufacturing cost, and mechanism action. The effect of simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

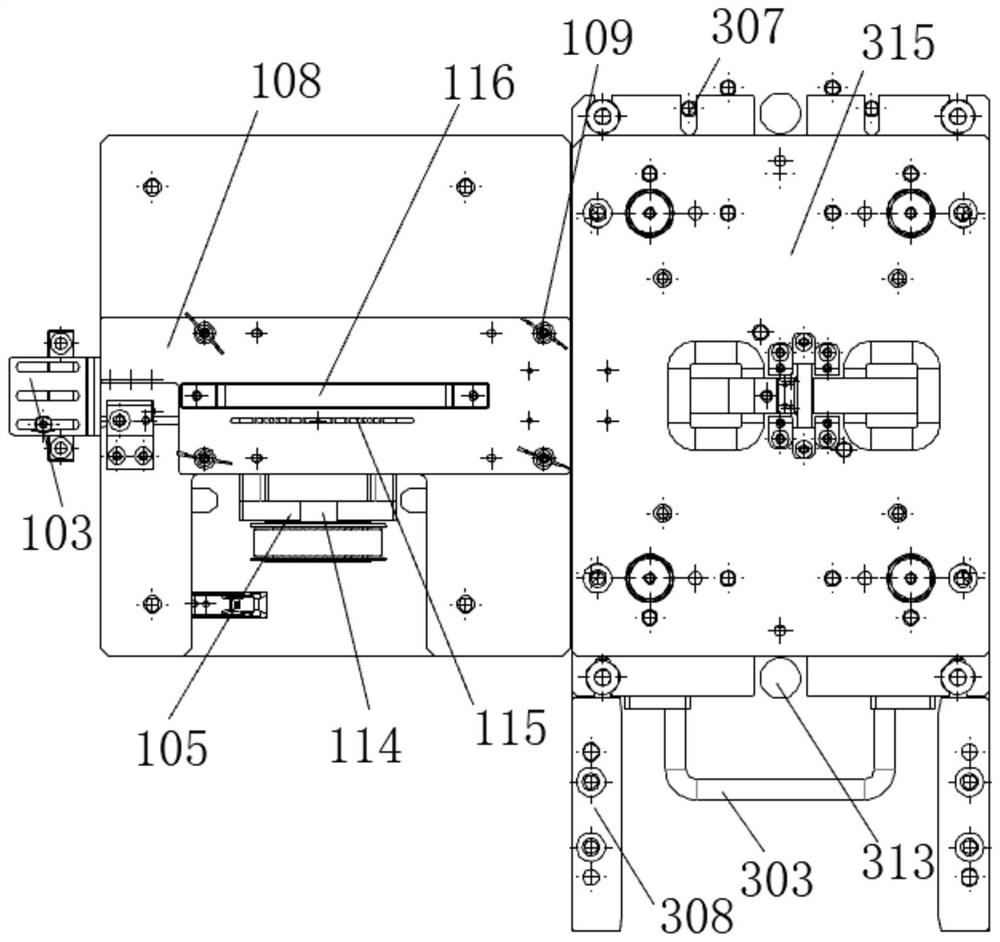

[0033] see Figure 1-10 , the present invention provides a technical solution: a high-precision automatic feeding and cutting mechanism, including a feeding assembly 100, a positioning assembly 200, and a cutting assembly 300, and the feeding assembly 100 and the cutting assembly 300 are connected through the positioning assembly 200 ;

[0034] The feed assembly 100 includes a first fixed plate 108, the top of the first fixed plate 108 is provided with a manual positioning mechanism 101, the bottom of the first fixed plate 108 is fixedly connected with a straight plate 110, and one side of the straight plate 110 is provided with a braking mechanism, the straight plate One side of 110 is rotatably connected with high-precision ratchet 104 through rotating shaft 114;

[0035] The positioning assembly 200 includes an automatic positioning module 201;

[0036] The cutting assembly 300 includes two baffle plates 302, an adjustable stroke cylinder 304 is arranged between the two b...

Embodiment 2

[0045] The same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: the bottom of the second fixed plate 315 and the top of the moving plate 312 are all fixedly connected with a sleeve 313, the inside of the sleeve 313 is provided with a rectangular spring 306, and the top of the moving plate 312 The top is fixedly connected with several repeating positioning pins 307, and one side of the cutting die 310 is fixedly connected with a second handle 303; When installing, position the cutting die 310, push the spare die to the bottom and touch the repeat positioning pin 307, and then tighten the bolts to realize the rapid switching of the cutting die 310. After the auxiliary pressing belt knife, the standard The rectangular spring 306 acts in the sleeve 313, which c...

Embodiment 3

[0049] The same or corresponding components as those in Embodiment 2 use the corresponding reference numerals as in Embodiment 2. For the sake of simplicity, only the differences from Embodiment 2 will be described below. The difference between the embodiment 3 and the embodiment 2 is that: a tail detection probe 103 is provided on one side of the first fixing plate 108 . In the present invention, when each roll of material is used up, if the tailing detection probe 103 fails continuously, an alarm will be issued to remind the operator to replace the material tape roll in time, so as to provide more friendly human-computer interaction, remind the personnel when to change the material, and the butterfly The butterfly bolt 109 is easy to disassemble. Due to the risk of material being deformed and jammed, the butterfly bolt 109 needs to be quickly disassembled for the operator to troubleshoot. The accuracy of precise positioning in the separation from the stamping strip; the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com