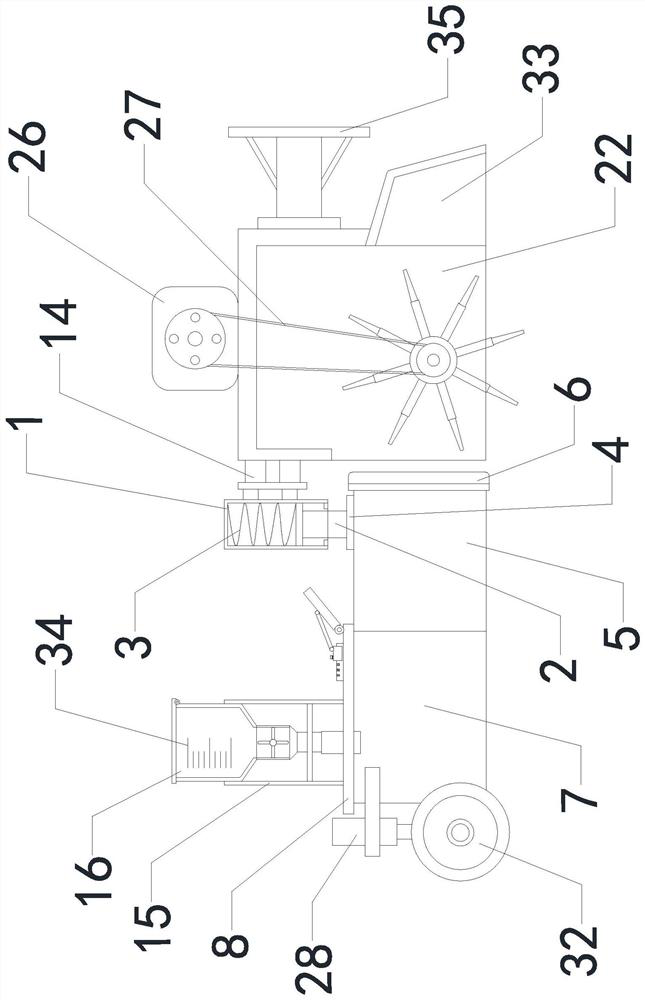

Soybean no-tillage ridging precision seeding technology and mechanical equipment

A kind of mechanical equipment and soybean technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of reducing ridging quality, poor practicability, and increasing soil compactness, so as to improve ridging quality, improve shaping effect, and improve The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

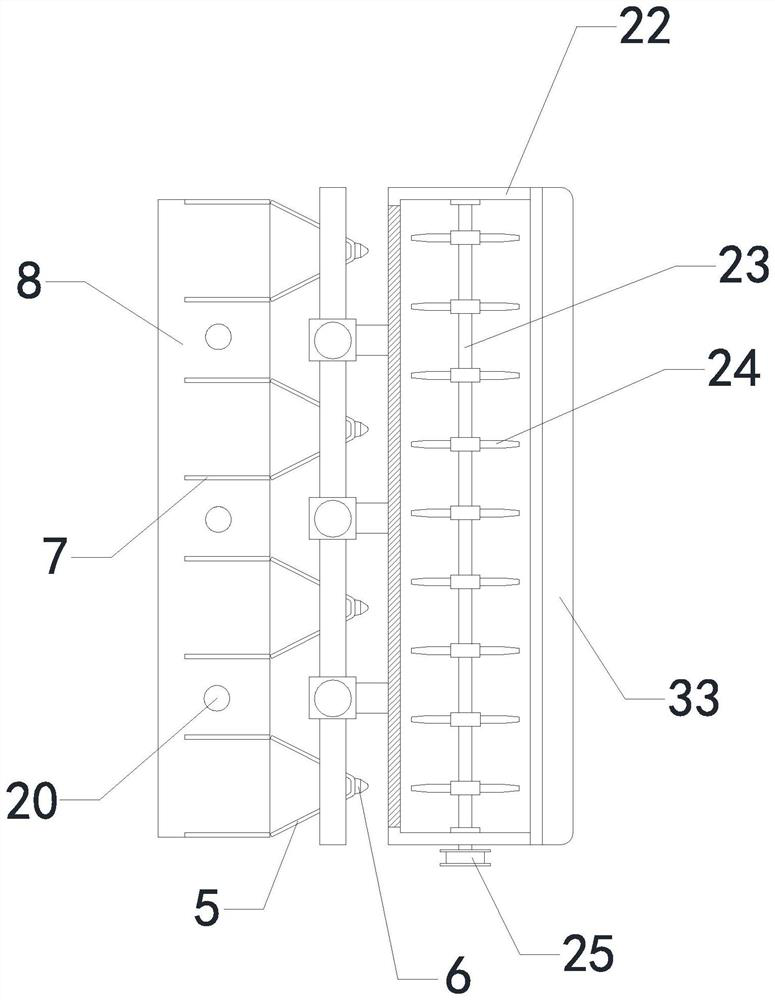

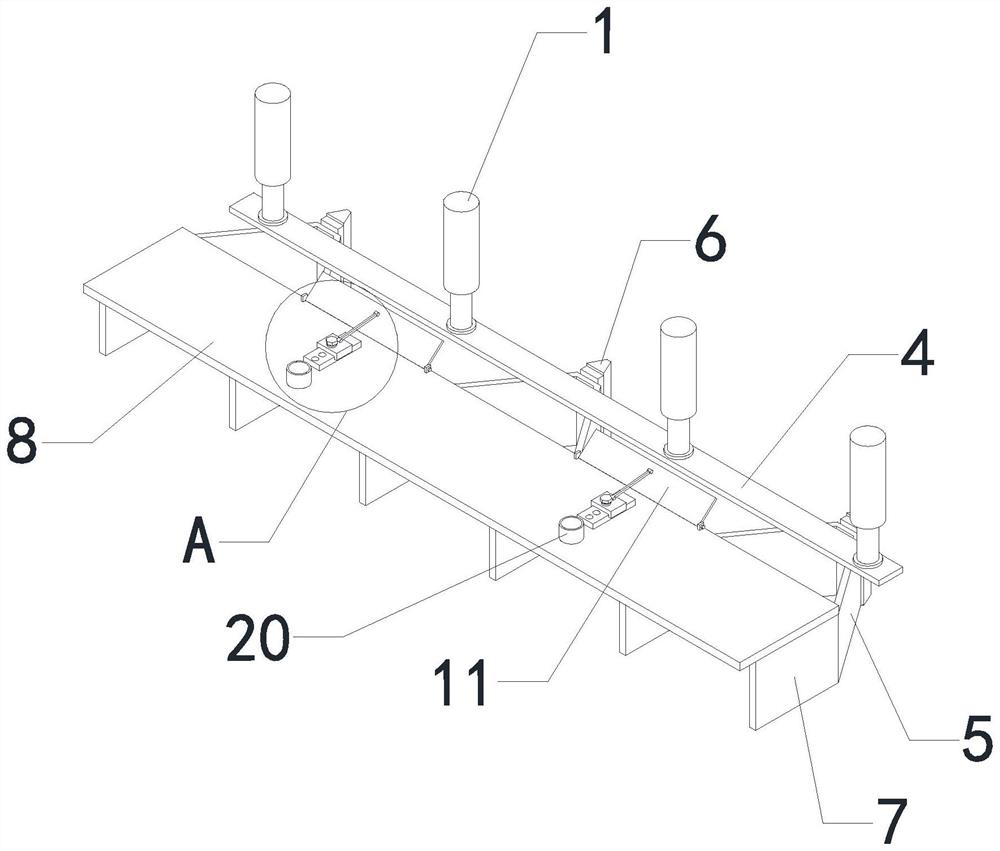

Embodiment 1

[0026]Multiple sets of first upper pillars 1 are installed on the outer sidewall of the soil breaking device through mounting brackets 14, the bottom ends of multiple sets of first upper pillars 1 are respectively provided with openings, and the tops of multiple sets of first lower pillars 2 are respectively slidably installed on multiple sets of first upper pillars 2. Inside the opening of the upper pillar 1, multiple groups of first springs 3 are installed in the openings of the multiple groups of the first upper pillar 1 respectively. The tops are all connected to the bottom ends of the connecting arms 4, and the shapes of the multi-group diverter plates 5 are all set in a "V" shape, and the multi-group headers 6 are respectively installed on the right end of the multi-group diverter plates 5, and the multi-group side plates 7 are respectively installed on the multi-group manifolds. The left end of the group flow plate 5, the bottom end of the top plate 8 are connected with ...

Embodiment 2

[0028] Multiple sets of first upper pillars 1 are installed on the outer sidewall of the soil breaking device through mounting brackets 14, the bottom ends of multiple sets of first upper pillars 1 are respectively provided with openings, and the tops of multiple sets of first lower pillars 2 are respectively slidably installed on multiple sets of first upper pillars 2. Inside the opening of the upper pillar 1, multiple groups of first springs 3 are installed in the openings of the multiple groups of the first upper pillar 1 respectively. The tops are all connected to the bottom ends of the connecting arms 4, and the shapes of the multi-group diverter plates 5 are all set in a "V" shape, and the multi-group headers 6 are respectively installed on the right end of the multi-group diverter plates 5, and the multi-group side plates 7 are respectively installed on the multi-group manifolds. The left end of the group flow plate 5, the bottom end of the top plate 8 are connected with...

Embodiment 3

[0030] A kind of soybean no-tillage ridge precise sowing technique comprises the following steps:

[0031] Step 1: Rotate the multiple sets of box lids 21 upward to open the feed ports at the top of the multiple sets of storage tanks 16, and place the soybean fertilizer inside the multiple sets of storage tanks 16 through the feed ports of the multiple sets of storage tanks 16;

[0032] Step 2: After the ridging device completes the soil ridging, multiple sets of first rotating shafts 18 are driven to rotate by turning on multiple sets of driving motors, and multiple sets of baffle plates 19 are used to transport the fertilizer downward after the multiple sets of first rotating shafts 18 rotate. Make the fertilizer fall to the top of the ridging soil through the connecting pipe 20, and at this time, the ridging operation is carried out during the continuous advancement of the equipment, so that the baffle plate 19 continuously transports the fertilizer;

[0033] Step 3: Soybea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com