A magnetic block assembly device for an outer rotor

A technology of assembling device and outer rotor, applied in electromechanical devices, manufacturing stator/rotor body, magnetic circuit, etc., can solve problems such as poor flexibility, crushed magnetic blocks, scratched magnetic blocks, etc., and achieves the effect of convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

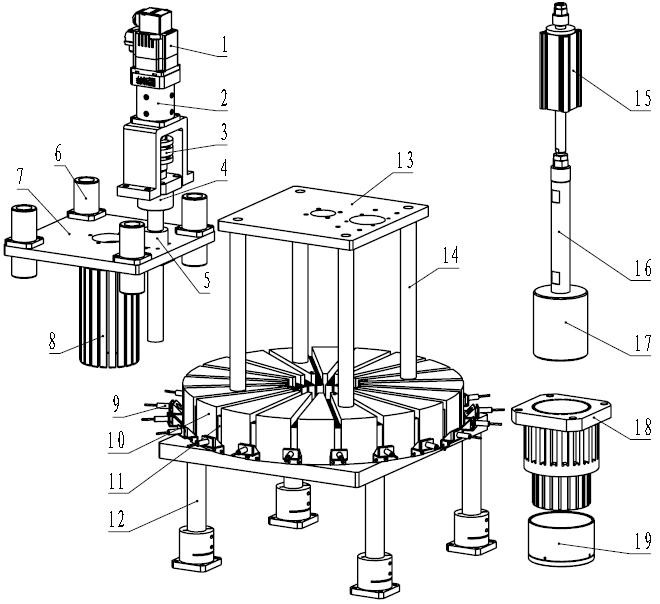

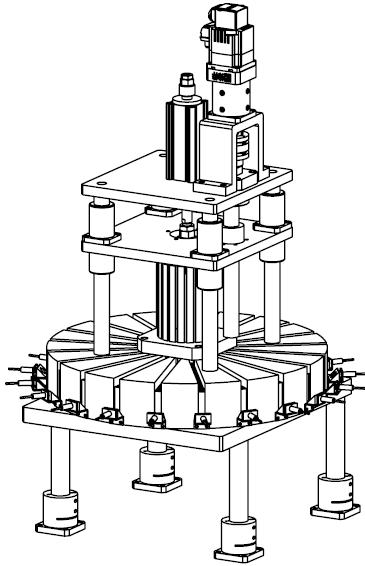

[0037] Such as figure 1 and figure 2 As shown, four columns 12 support a mounting plate, and a circular magnetic block material tray 10 is arranged on the mounting plate. A through hole is provided in the center of the magnetic block material plate 10 and a magnetic block guide seat 18 is arranged. A plurality of rectangular through slots arranged radially are arranged in the cloth, and a magnetic block 11 is housed in the rectangular through slots.

[0038] In a specific implementation, a plurality of magnetic blocks 11 are installed in the rectangular slot of the magnetic block guide seat 18 , and the plurality of magnetic blocks 11 are magnetically attracted and tightly stacked along the radial direction of the magnetic block guide seat 18 .

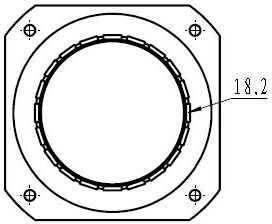

[0039] Such as Figure 3 to Figure 5 As shown, the inner part of the upper part of the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com