Method for improving tear resistance and torsion performance of plate spring bushing and plate spring bushing

A technology of leaf spring bushing and torsion performance, which is applied in the direction of spring, elastic suspension, transportation and packaging, etc. It can solve the problems of axial movement and prolapse, so as to improve the service life, reduce axial movement, Enhance the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

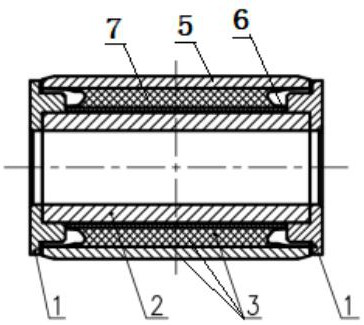

[0048] by attaching Figure 1-9 It can be seen that the present invention relates to a leaf spring bushing, comprising a T-shaped retaining ring 1, an inner sleeve 2 and a vulcanized body 3, the T-shaped retaining ring 1 is a ring structure with a T-shaped cross section; the inner sleeve 2 is Surface-hardened tubular structure; vulcanized body 3 includes split outer tile cover 5, self-lubricating sleeve 6 and rubber body 7, rubber body 7 is a multi-layer rubber structure, rubber body 7 and self-lubricating sleeve 6 shrink to form a cavity 4. The inner casing 2 is press-fitted into the inner hole of the vulcanized body 3 with an interference fit; the T-shaped retaining ring 1 is interference-fitted at both ends of the inner casing 2 .

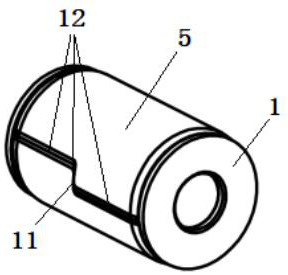

[0049] In this embodiment, the two split outer tile covers 5 are fitted on the outermost layer of the leaf spring bushing, and the two split outer tile covers 5 are fitted with dislocated "Z" shaped slits 12. There is a gap between the tile cov...

Embodiment 2

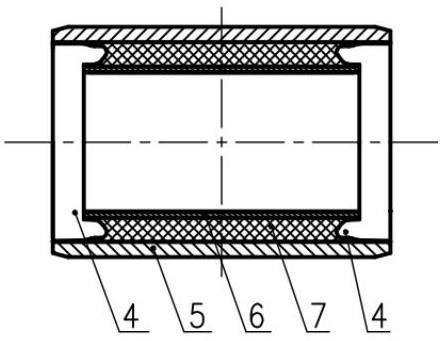

[0053] The principle of embodiment two is the same as that of embodiment one, but the combination structure is slightly different. Figure 7 It can be seen that the present invention relates to a leaf spring bushing, which includes a skeleton and a vulcanized body. The skeleton is assembled from two retaining rings and an inner sleeve; the vulcanized body is press-fitted on the inner sleeve with an interference fit. Located between two stop rings; the vulcanized body includes a self-lubricating sleeve, a split outer tile cover, a spacer and a rubber elastic body; the vulcanized body is a cavity structure with both ends retracted, and the vulcanized body is inserted into the vulcanized body The cavity forms a fit.

[0054] Further, the retaining ring is a T-shaped structure, which is interference-fitted on the inner casing and inserted into the cavity of the vulcanized body, and at the same time realizes the axial movement and radial deformation limit of the vulcanized body, in...

Embodiment 3

[0060] The principle of the third embodiment is the same as that of the first embodiment, but the combined structure is slightly different, and the attached Figure 8 It can be seen that the present invention relates to a leaf spring bushing, which includes a skeleton and a vulcanized body. The skeleton is assembled from two retaining rings and an inner sleeve; the vulcanized body is press-fitted on the inner sleeve with an interference fit. Located between two stop rings; the vulcanized body includes a self-lubricating sleeve, a split outer tile cover, a spacer and a rubber elastic body; the vulcanized body is a cavity structure with both ends retracted, and the vulcanized body is inserted into the vulcanized body The cavity forms a fit.

[0061] It’s just that the split outer tile cover is a slit matching structure. When the two split trapezoidal slit outer tile covers are combined to form a “Z”-shaped interface gap on the two sides, and the middle section is oblique Arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com