Large bearing quenching stirring device

A stirring device and bearing technology, applied in the field of bearing quenching, can solve problems such as uneven oil temperature, soft spots on the workpiece, and accelerated oil aging, and achieve the effect of convenient work and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the structure and function of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

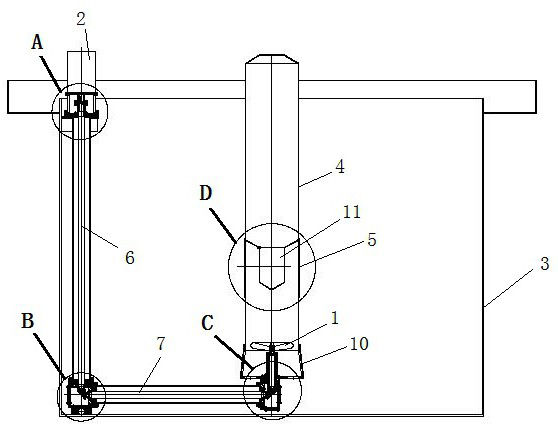

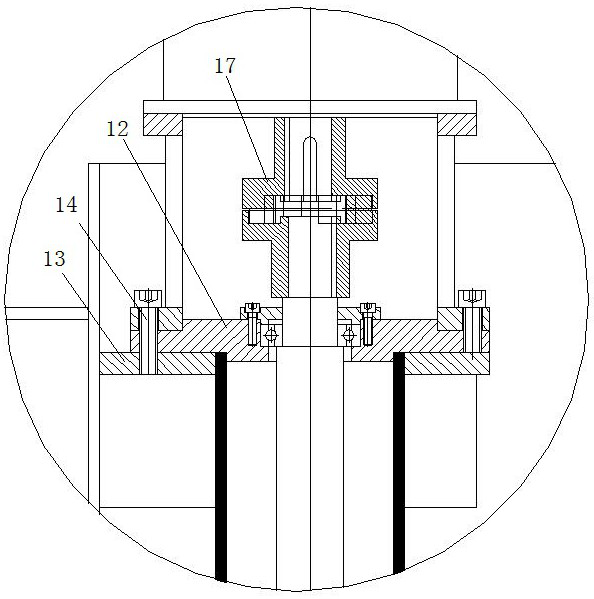

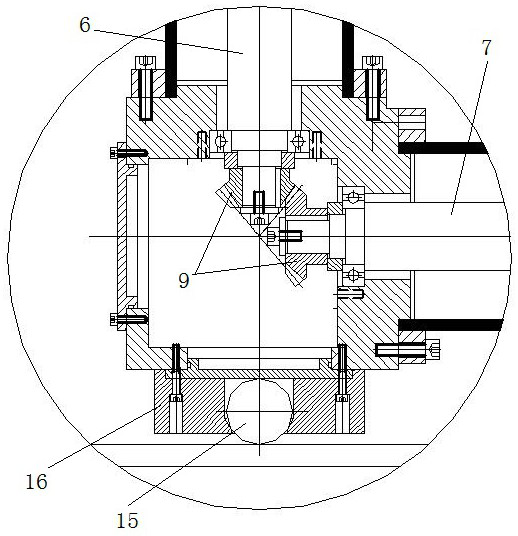

[0022] See attached Figure 1-5 , a large-scale bearing quenching stirring device, including a propeller 1 and a vertical motor 2, the propeller 1 is arranged in the quenching oil pool 3, the vertical motor 2 drives the propeller 1 to move through a transmission mechanism, and the external cover of the propeller 1 is provided with a guide Tube 4, one end of guide tube 4 close to the bottom of the quenching oil pool is open, and several guide ports 5 are set on the guide tube along the circumference, and the guide ports 5 are connected with guide tube 4 and quenching oil pool 3, and several guide tubes The flow port is located above the propeller 1, the height of the flow guide port 5 matches the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com