High-simulation digital mold ceramic tile and preparation method thereof

A ceramic tile and mold technology, applied in the field of architectural ceramics, can solve the problems of limited use conditions, pattern texture and color, glossy transition, and residue at the line, so as to improve the degree of automation and production efficiency, uniform gloss, and economical The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

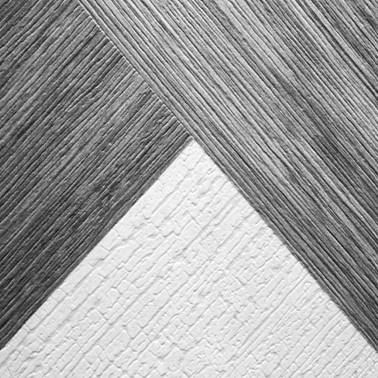

Image

Examples

Embodiment 1

[0088] A method for preparing high-simulation digital mold ceramic tiles, comprising the following steps:

[0089] (1) Press the ceramic green body and dry it. When the temperature of the green body drops to 85°C, use a high-pressure spray gun to spray water evenly on the surface of the green body, and control the amount of water sprayed to 10g / m 2 ;

[0090] (2) Use the AIRPOWER high-pressure spray cabinet with 6 spray guns to spray the bottom glaze, and the specific gravity of the bottom glaze is 1.55g / cm 3 , glaze amount 120g / m 2 , after the bottom glaze layer is dried, the glaze component is glaze A1;

[0091] (3) According to the pre-designed wood grain texture pattern, use the new Jingtai digital inkjet printer equipped with Xaar GS40 nozzle to print digital mold ink, and control the printing ink volume to 62g / m 2 , over the drying line, the drying temperature is 110°C, the drying time is 3min, the average particle size of the mold ink is 265nm, the maximum particle s...

Embodiment 2

[0158] A method for preparing high-simulation digital mold ceramic tiles, comprising the following steps:

[0159] (1) Press the ceramic green body and dry it. After the temperature of the green body drops to 90°C, use a high-pressure spray gun to spray water evenly on the surface of the green body, and control the amount of water sprayed to 5g / m 2 ;

[0160] (2) The bottom glaze is poured with a linear glazer, and the specific gravity of the bottom glaze is 1.82g / cm 3 , glaze amount 350g / m 2 , and then pass through the drying line, the drying temperature is 120°C, the drying time is 3 minutes, and the glaze component of the bottom glaze layer is glaze A2;

[0161] (3) According to the pre-designed leather texture pattern, use Jingtao digital inkjet printer equipped with Seiko RC1536 nozzle to print digital mold ink, the ink volume is 45g / m 2 , through the drying line, the drying temperature is 120°C, the drying time is 3min, the average particle size of the mold ink is 320...

Embodiment 3

[0228] A method for preparing high-simulation digital mold ceramic tiles, comprising the following steps:

[0229] (1) Press the ceramic green body and dry it. When the temperature of the green body drops to 90°C, use a high-pressure spray gun to spray water evenly on the surface of the green body, and control the amount of water sprayed to 8g / m 2 ;

[0230] (2) Use AIRPOWER high-pressure spraying cabinet to spray the bottom glaze, the specific gravity of the bottom glaze is 1.50g / cm 3 , glaze amount 150g / m 2 , and then pass through the drying line, the drying temperature is 110°C, the drying time is 3 minutes, and the glaze component of the bottom glaze layer is glaze A3;

[0231] (3) According to the pre-designed horizontal stripe texture pattern, use hope digital inkjet printer (equipped with Xingguang 1024HF nozzle) to print and dry the digital mold ink, and control the ink volume to 75g / m 2 ;Pass the drying line, the drying temperature is 180°C, the drying time is 5min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com