Multi-stack integrated long-life fuel cell system

A fuel cell system, fuel cell stack technology, applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problem of reducing the durability of fuel cell engines, restricting the commercialization of fuel cell vehicles, fuel cell engine Poor durability and other problems, to avoid short-board effect, low voltage saving, and avoid maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

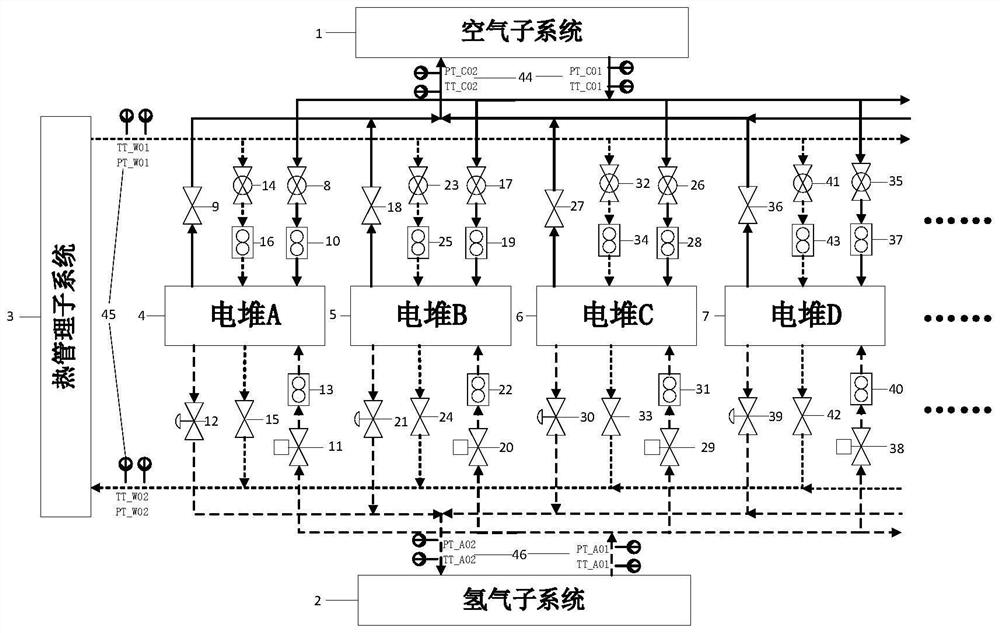

[0045] This embodiment proposes a multi-stack integrated long-life fuel cell system, such as image 3 and Figure 4 As shown, it includes hydrogen subsystem 2, air subsystem 1, thermal management subsystem 3, engine control module and multiple power output submodules connected in parallel.

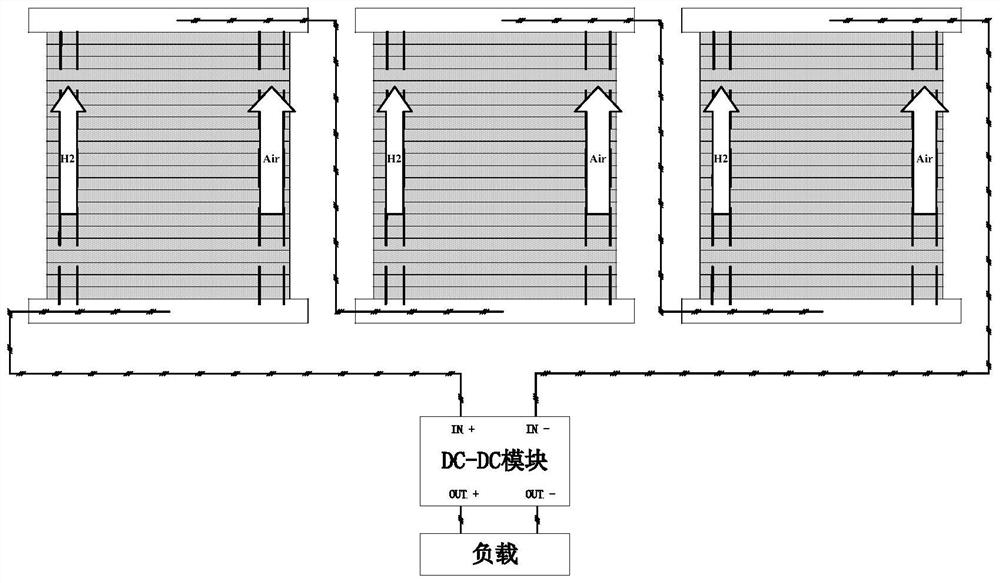

[0046] Such as Figure 4 As shown, the power output sub-module is composed of a fuel cell stack and a DC-DC module, and the first four power output sub-modules include stack A4 and DC-DC module 47 of stack A, stack B4 and stack A The DC-DC module 48 of B, the DC-DC module 49 of stack C6 and stack C, the DC-DC module 50 of stack D7 and stack D; the positive and negative poles of each stack are connected with the corresponding DC-DC module The input ends are connected, and the output ends of each DC-DC module are connected to the same group of lines with the same output voltage, which is used to supply power to multiple external lithium batteries 51 , and the load 52 takes power from the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com