Split type feeding device and using method thereof

A split-type, sliding device technology, applied in packaging, liquid handling, loading/unloading, etc., can solve the problems of sewage overflow, secondary pollution of the environment, serious garbage dumping, etc., and achieve stable structure, high safety, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

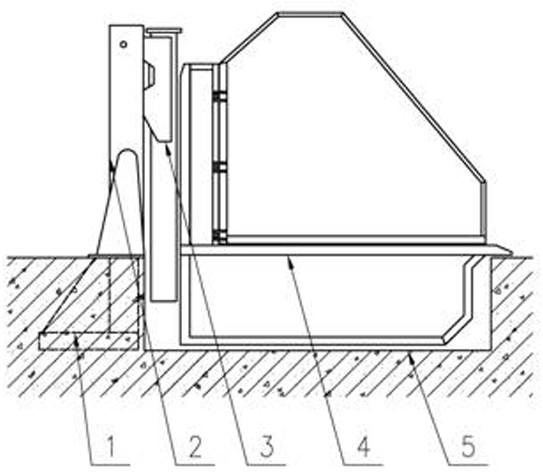

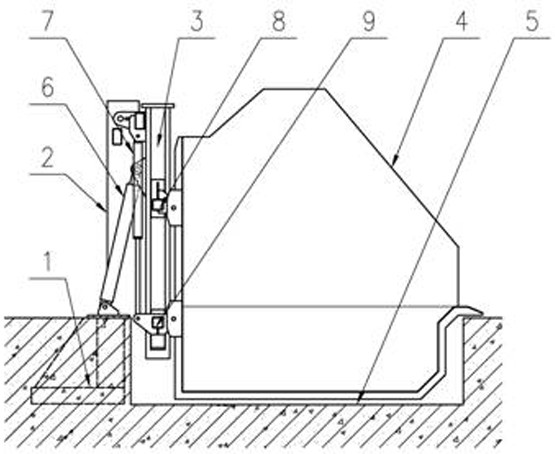

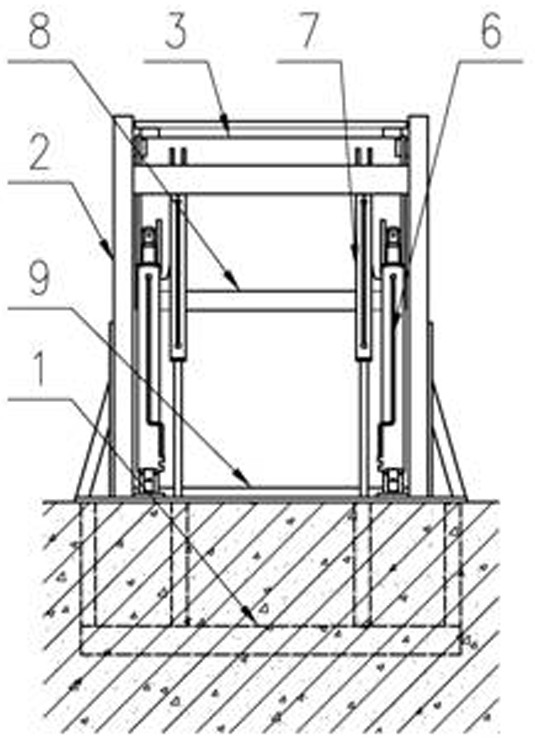

[0045] As a preferred embodiment of the present invention, this embodiment provides a split-type feeding device, including embedded parts 1, columns 2, flip frame 3, hopper 4, telescopic parts, upper sliding device 8 and lower sliding device 9, The column 2 is fixedly installed on the embedded part 1, and one end above the overturning frame 3 is fixed on the column 2 through a hinge. The telescopic part includes a lifting telescopic part 7 and a turning telescopic part 6. Above the overturn frame 3, one end is hingedly connected with the lower sliding device 9, one end of the overturn telescopic member 6 is hingedly fixed on the column 2, and one end is hinged with the overturn frame 3, and the overturn frame 3 is provided with a chute, and the upper slide device 8 One end of the lower slide device 9 is hingedly fixed with the top of the back of the hopper 4, the left and right sides are provided with sliders, one end of the lower sliding device 9 is hingedly fixed with the bot...

Embodiment 2

[0048] As another preferred embodiment of the present invention, this embodiment provides a split-type feeding device, including embedded parts 1, columns 2, turning frame 3, hopper 4, telescopic parts, upper sliding device 8 and lower sliding device 9 , the column 2 is fixedly installed on the embedded part 1, and one end above the overturn frame 3 is fixed on the column 2 through a hinge. Above the overturning frame 3, one end is hingedly connected with the lower sliding device 9, one end of the overturning telescopic member 6 is hinged and fixed on the column 2, and one end is hinged with the overturning frame 3, the overturning frame 3 is provided with a chute, and the upper sliding device One end of 8 is hingedly fixed to the top of the back of the hopper 4, sliders are arranged on the left and right sides, one end of the lower sliding device 9 is hingedly fixed to the bottom of the back of the hopper 4, and the other end is hingedly fixed to the lifting telescopic member ...

Embodiment 3

[0051] As another preferred embodiment of the present invention, this embodiment provides

[0052] A split-type feeding device, comprising a pre-embedded part 1, a column 2, a flip frame 3, a hopper 4, a telescopic part, an upper sliding device 8 and a lower sliding device 9, the column 2 is fixedly installed on the pre-embedded part 1, One end above the overturning frame 3 is fixed on the column 2 through a hinge, and the telescopic part includes a lifting telescopic part 7 and a turning telescopic part 6. One end of the lifting telescopic part 7 is hingedly fixed above the overturning frame 3, and one end is hinged with the lower sliding device 9 One end of the flip telescopic member 6 is hinged and fixed on the column 2, and one end is hinged with the flip frame 3. The flip frame 3 is provided with a chute, and one end of the upper sliding device 8 is hinged and fixed with the top of the back of the hopper 4. The side is provided with a slider, and one end of the lower slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com