Cup barrel shaping mechanism for automatic production of paper cups

An automatic production and shaping mechanism technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as increased product production costs, inconsistent finished product specifications, and paper tube forming that does not meet standard specifications, so as to ensure accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

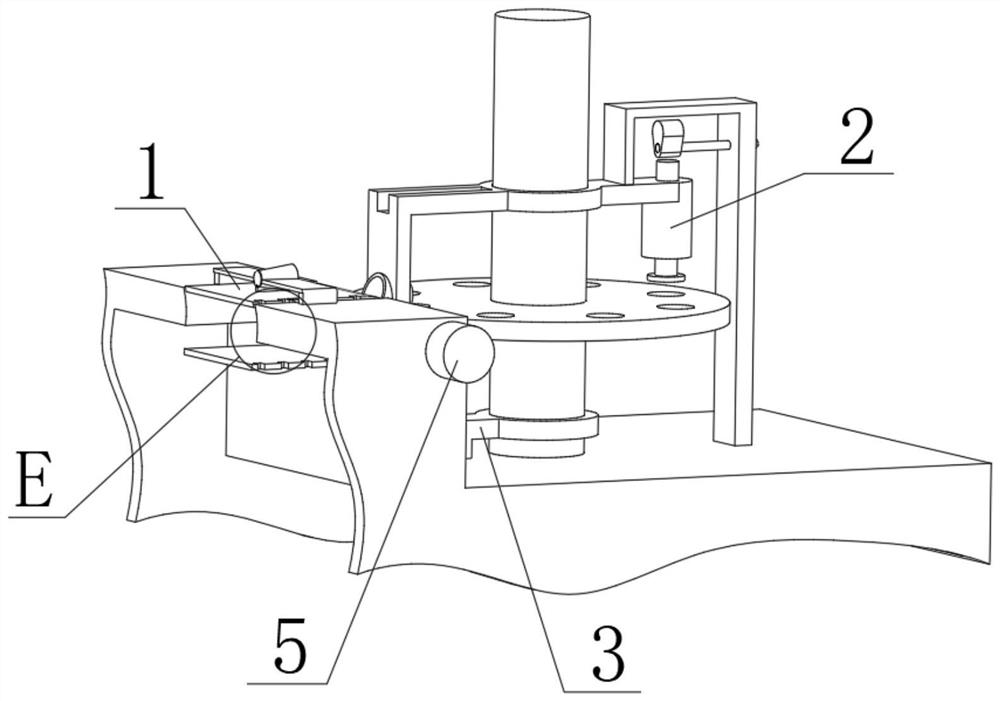

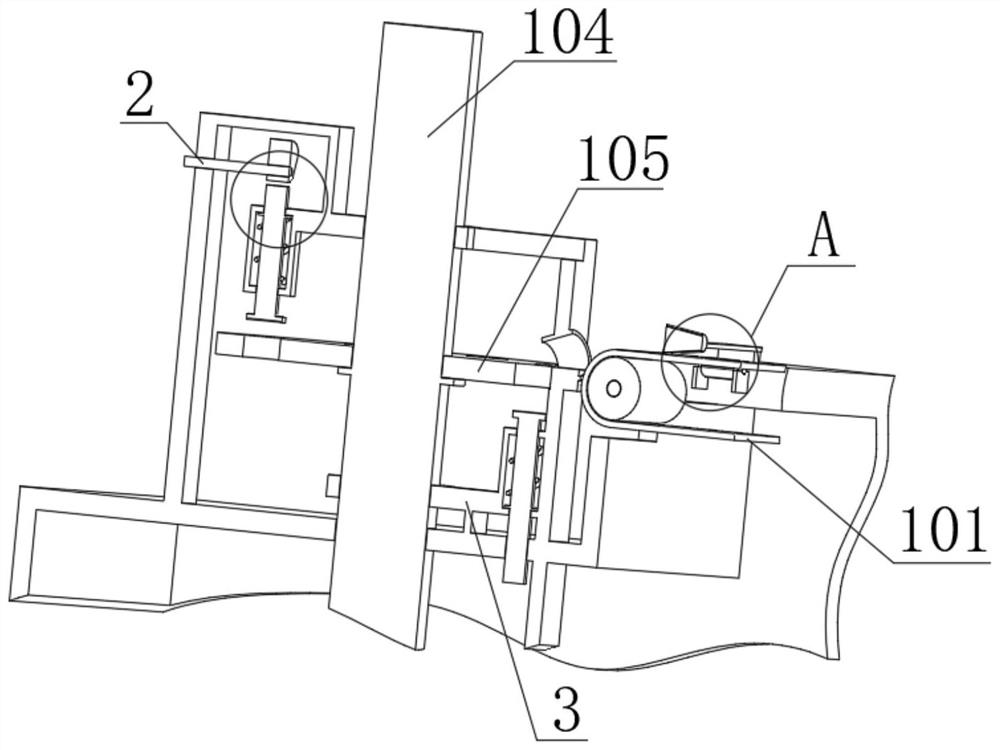

[0047] Embodiment 1: A cup barrel shaping mechanism for automatic production of paper cups, including a forming component 1, a pressing component 2, and a top mold 3, the forming component 1 is fixedly connected to the upper surface of the frame, and the top of the forming component 1 is fixedly arranged There is a pressing assembly 2, and a top mold 3 is fixedly arranged below the forming assembly 1.

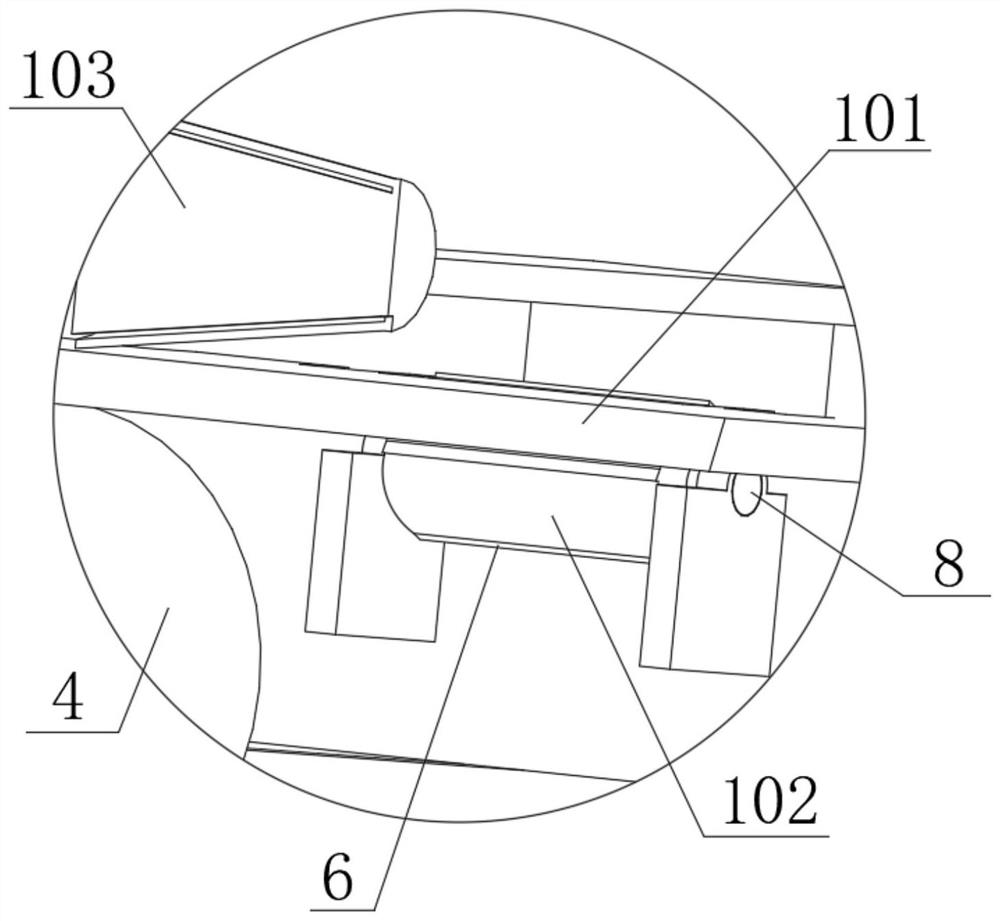

[0048] The molding assembly 1 includes a conveyor belt 101, a forming roller mold 103, a paper pushing shaft 104 and a cup holder 105. The conveyor belt 101 is fixedly arranged on the upper surface of the frame, and the molding roller mold 103 is fixedly arranged above the conveyor belt 101. In addition, a bearing at one end of the conveyer belt 101 is connected with a paper pushing shaft 104 , and a side surface of the paper pushing shaft 104 is fixedly connected with a cup holder 105 .

[0049] One side of the conveyer belt 101 is fixedly provided with a paper reel 102, and t...

Embodiment 2

[0053] Embodiment 2: A cup barrel shaping mechanism for automatic production of paper cups, including a forming component 1, a pressing component 2, and a top mold 3, the forming component 1 is fixedly connected to the upper surface of the frame, and the top of the forming component 1 is fixedly arranged There is a pressing assembly 2, and a top mold 3 is fixedly arranged below the forming assembly 1.

[0054] The pressing assembly 2 includes a fixed rod 201, a pressing rod 203, a return spring 204 and a periodic cam 206. The fixing rod 201 is fixedly arranged above the molding assembly 1, and the side of the fixing rod 201 is provided with a pressing rod 203, and the side of the pressing rod 203 is provided with There is a return spring 204 , and the end of the pressing rod 203 away from the molding assembly 1 is provided with a periodic cam 206 .

[0055] The fixed rod 201 is fixedly connected with the frame. The side of the fixed rod 201 close to the molding assembly 1 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com