Electrode assembly and electrochemical device

An electrode assembly and negative electrode technology, applied in the field of electrochemical devices, can solve the problems of undervoltage in the cell area, poor surface consistency of the pole piece, thermal runaway of internal short circuit, etc., so as to improve the undervoltage problem, prevent the short circuit, reduce the Effects of Risk of Lithium Precipitation Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

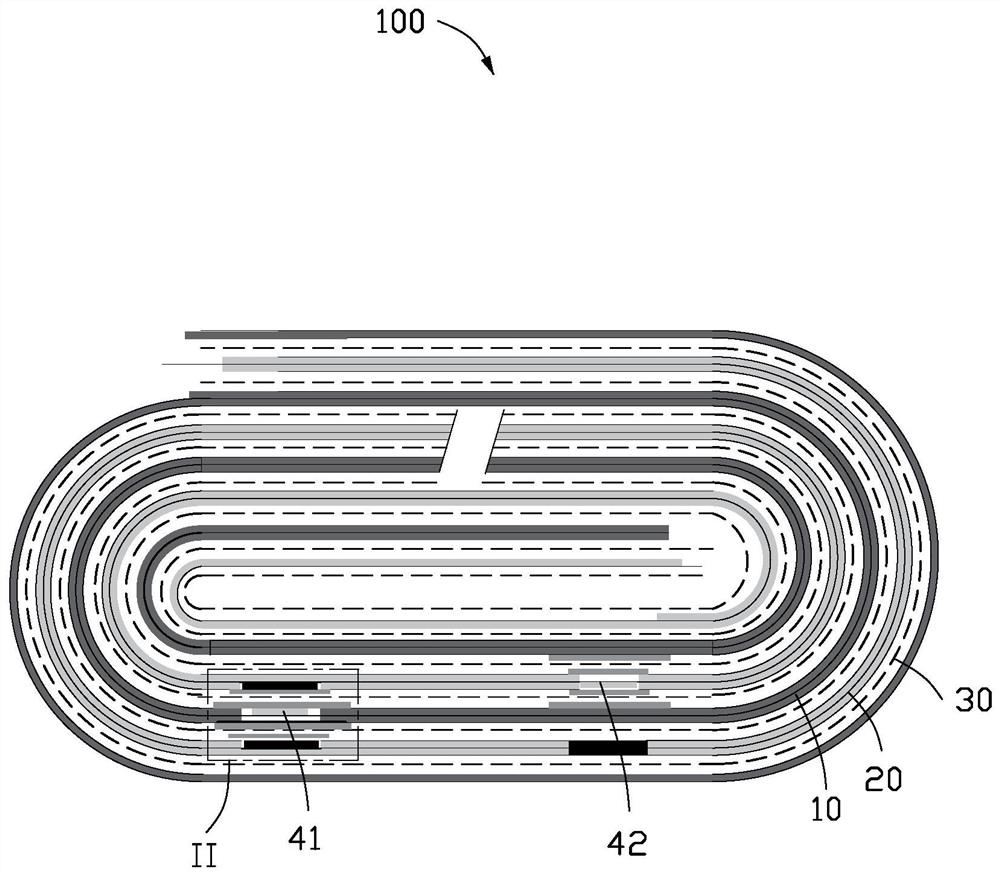

[0076] see figure 1 , figure 2 with image 3 , the electrode assembly 100 includes a positive electrode sheet 10 , a negative electrode sheet 20 , a separator 30 , a positive electrode tab 41 and a negative electrode tab 42 . The positive electrode sheet 10 and the negative electrode sheet 20 are stacked and wound, and the separator 30 is disposed between the positive electrode sheet 10 and the negative electrode sheet 20 . The positive tab 41 is electrically connected to the positive tab 10 , and the negative tab 42 is electrically connected to the negative tab 20 .

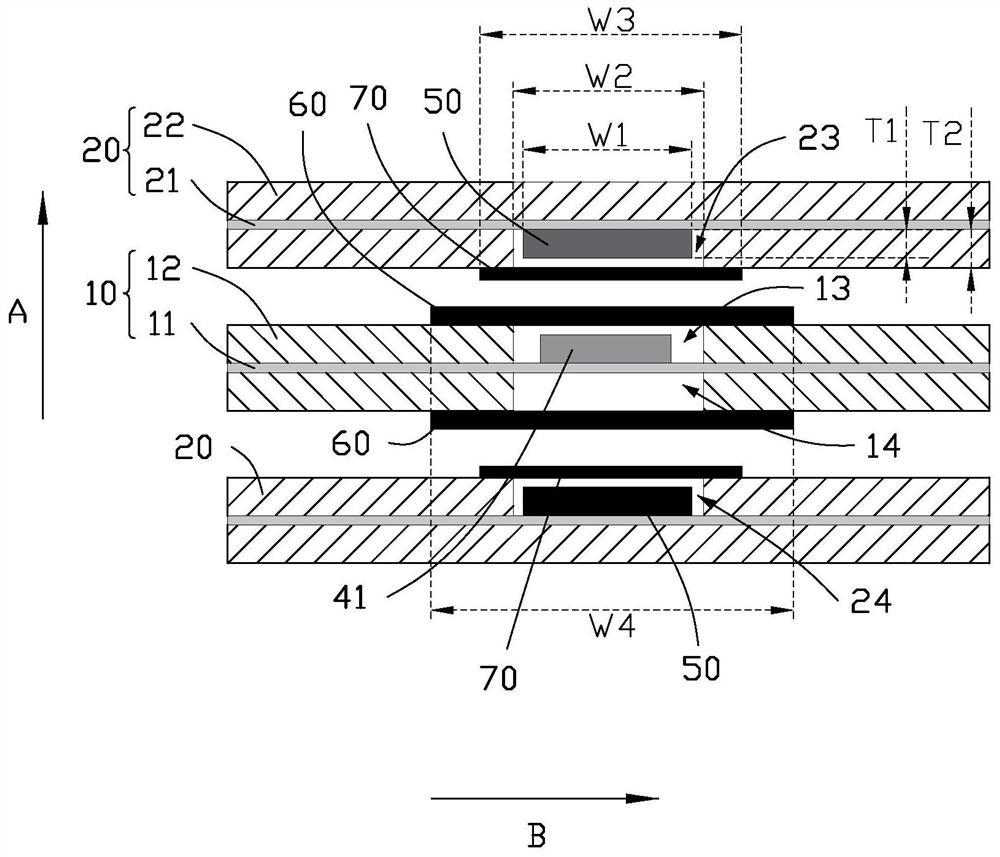

[0077] Specifically, see figure 2 , the positive electrode sheet 10 includes a positive electrode current collector 11 and a positive electrode active material layer 12 disposed on the surface of the positive electrode current collector 11 . In this embodiment, the positive electrode active material layers 12 are respectively provided on opposite sides of the positive electrode current collector 11 . The ...

no. 2 example

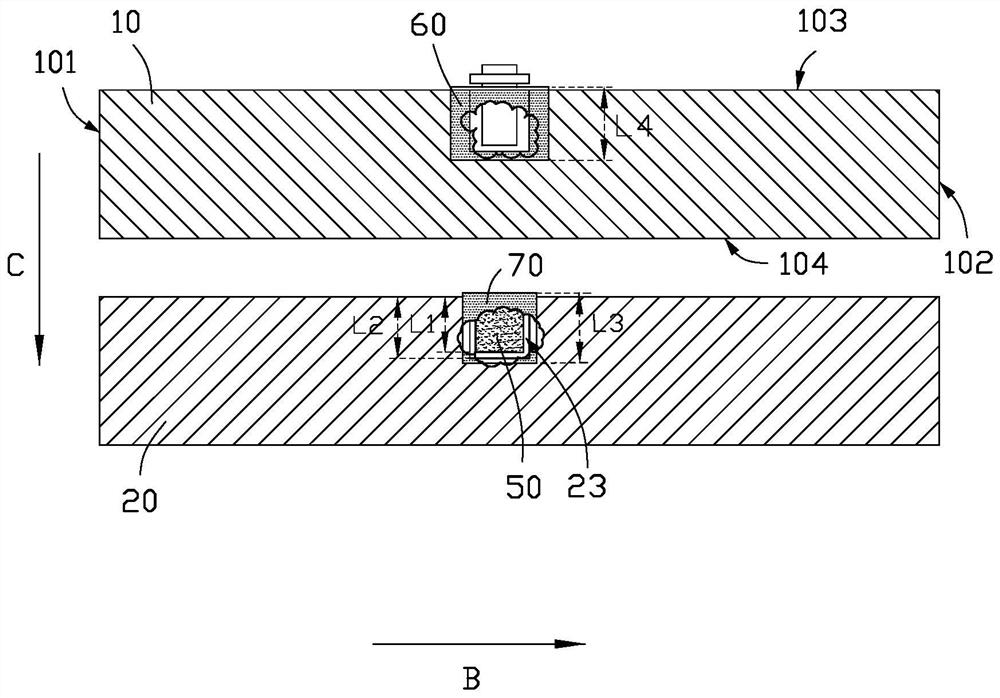

[0092] see Figure 4 , Figure 5 with Image 6 , the electrode assembly 200 of the second embodiment is substantially the same as the electrode assembly 100 of the first embodiment, the difference is that the negative electrode sheet 20 of the electrode assembly 200 is not provided with a second insulation covering the second groove 23 and the fourth groove 24 70 pieces. Since the second insulating member 70 is omitted, the size of the first insulating member 60 can be reduced correspondingly, which is beneficial to improve the energy density of the electrode assembly 200 .

[0093] In the second embodiment, the dimensional relationship between the second groove 23 and the first protective glue 50 satisfies: 1mm≤L2-L1≤5mm, 1mm≤W2-W1≤5mm, 0μm≤T2-T1≤20μm.

[0094] The dimensional relationship between the first insulating member 60 and the second groove 23 satisfies 1mm≤L4-L2≤10mm, 1mm≤W4-W2≤10mm.

no. 3 example

[0096] see Figure 7 , Figure 8 with Figure 9 The electrode assembly 300 of the third embodiment is substantially the same as the electrode assembly 100 of the first embodiment, the difference is that in the electrode assembly 300, the first protective glue 50 fills the second groove 23 and the fourth groove 24 in an equal area, The peripheral side of the first protective glue 50 is in contact with the negative electrode active material layer 22 to eliminate the gap between the first protective glue 50 and the periphery of the second groove 23 or the fourth groove 24 . The first protective glue 50 will not produce fluidity after curing, and eliminating the gap in the groove is beneficial to avoid the overflow of the active material when the subsequent electrode assembly 300 is under pressure, and improve the pressure resistance and service life of the electrode assembly 300 .

[0097] see again Figure 8 with Figure 9 , the width of the first protective glue 50 is W1, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com