An anti-return air intake structure for a rotary detonation combustion chamber

A technology of air intake structure and combustion chamber, which is applied in the field of aero-engines, can solve the problems of large total pressure loss in the combustion chamber, and achieve the effect of increasing the total pressure gain and reducing the impact on performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

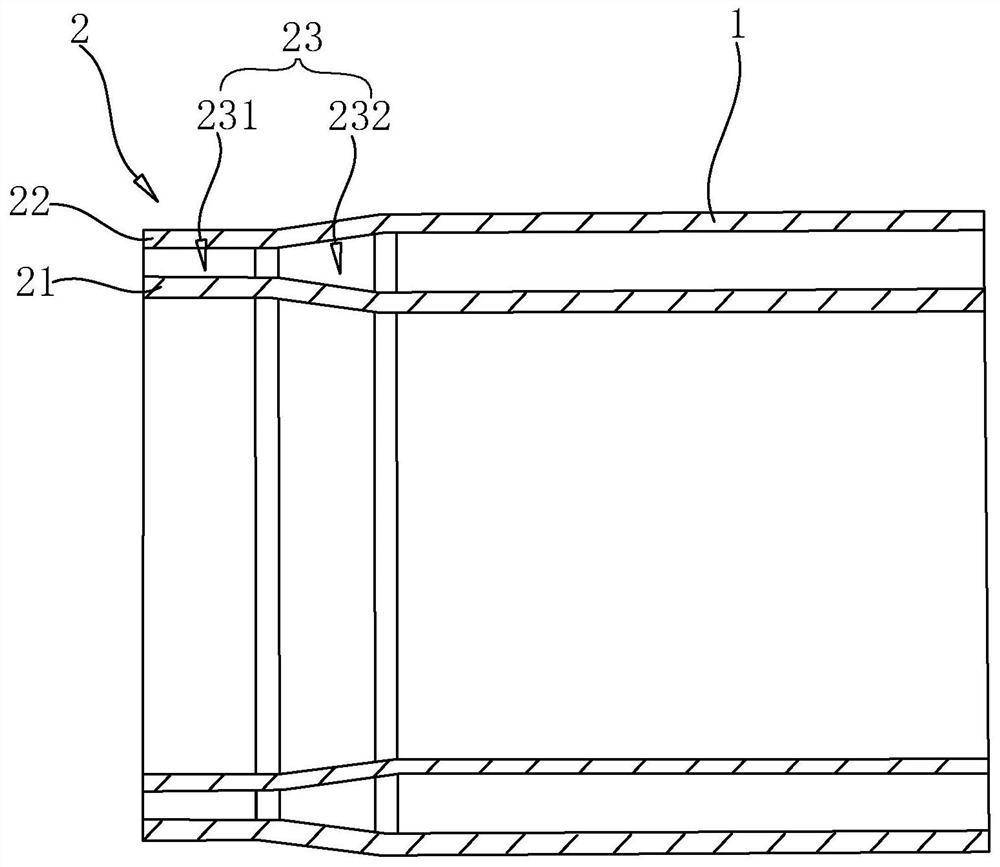

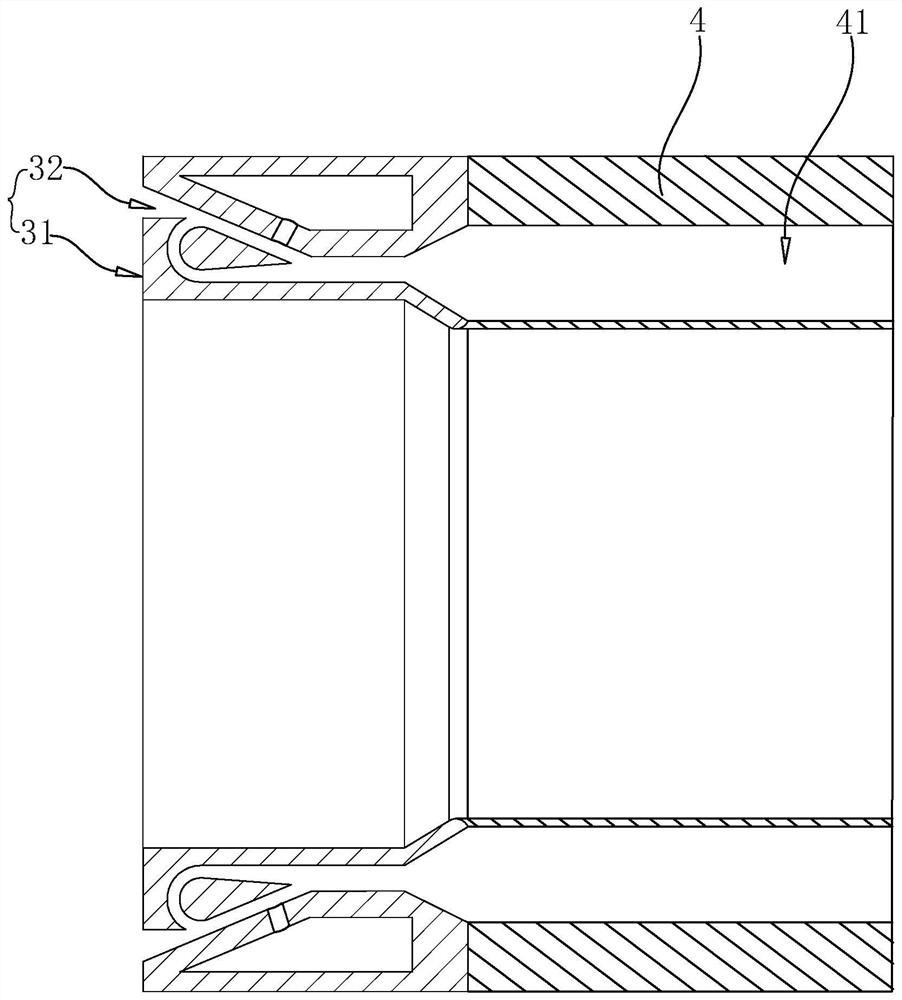

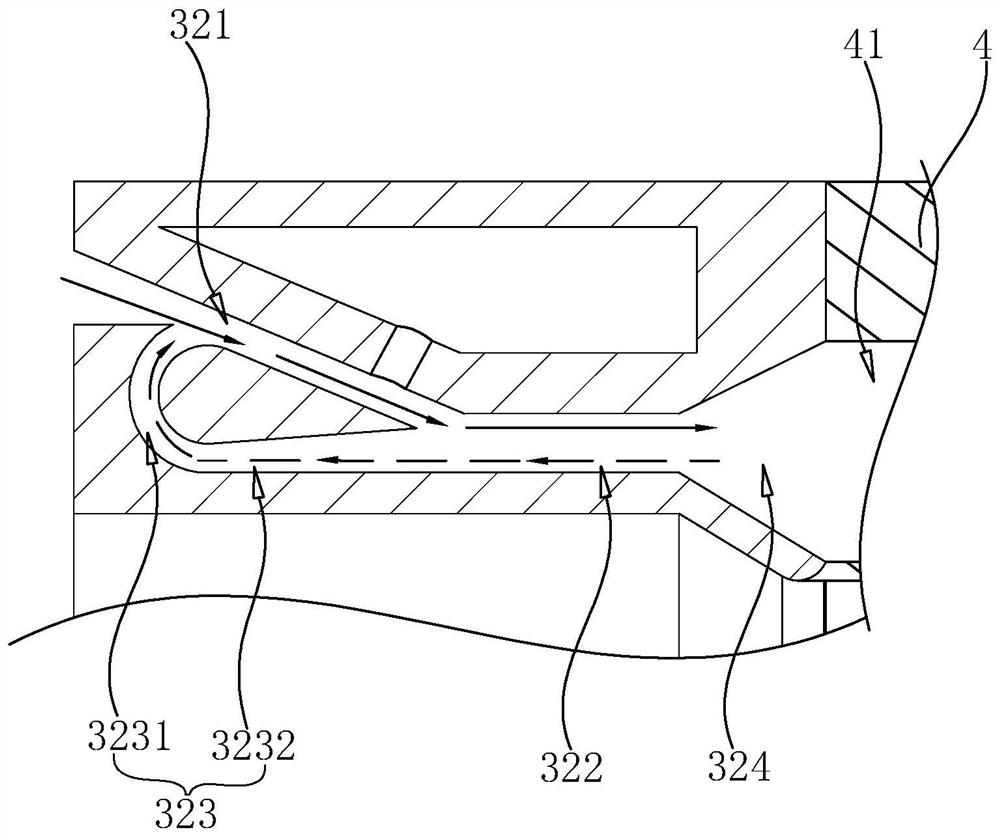

[0041] like figure 2 As shown, a rotary detonation combustion chamber anti-return air intake structure includes a Tesla valve 3 that communicates with the rotary detonation combustion chamber 4 and is snap-fitted at the inlet of the rotary detonation combustion chamber 4 . The Tesla valve 3 includes a casing 31 and a flow channel 32. The casing 31 is coaxially clamped to the outer wall of the rotary detonation combustion chamber 4. The flow channel 32 is opened in the casing 31, and the inlet end of the flow channel 32 is used for introducing air. , the outlet end of the flow channel 32 communicates with the annular channel 41 of the rotary detonation combustion chamber 4 .

[0042] like figure 2 , image 3 As shown, the flow channel 32 includes an intake channel 321, a connecting channel 322, an arc-shaped return channel 323 and an expansion channel 324; one end of the intake channel 321 is used to introduce air, and the other end communicates with the connecting channel ...

Embodiment 2

[0055] like Figure 8 , Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the housing 31 includes a first connection cylinder 311, a second connection cylinder 312 and a flow guide block 313, and the first connection cylinder 311 is coaxially sleeved on the second connection cylinder 311. Inside the barrel 312 , the guide block 313 is coaxially fixed between the first connecting barrel 311 and the second connecting barrel 312 .

[0056] The implementation principle of Embodiment 2 is the same as that of Embodiment 1, and details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com