Jacquard cloth printing and dyeing process

A printing and dyeing process, jacquard cloth technology, applied in textiles and papermaking, liquid/gas/steam textile material processing, textile material processing, etc., can solve the problems of reducing cloth quality, cloth surface wrinkles, cloth appearance damage, etc., to achieve Avoid wrinkling or slipping, eliminate air bubbles, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] This embodiment provides a jacquard printing and dyeing process, comprising the following steps:

[0031] (1) singeing and desizing the woven gray cloth;

[0032] (2) Bleaching and mercerizing the gray cloth;

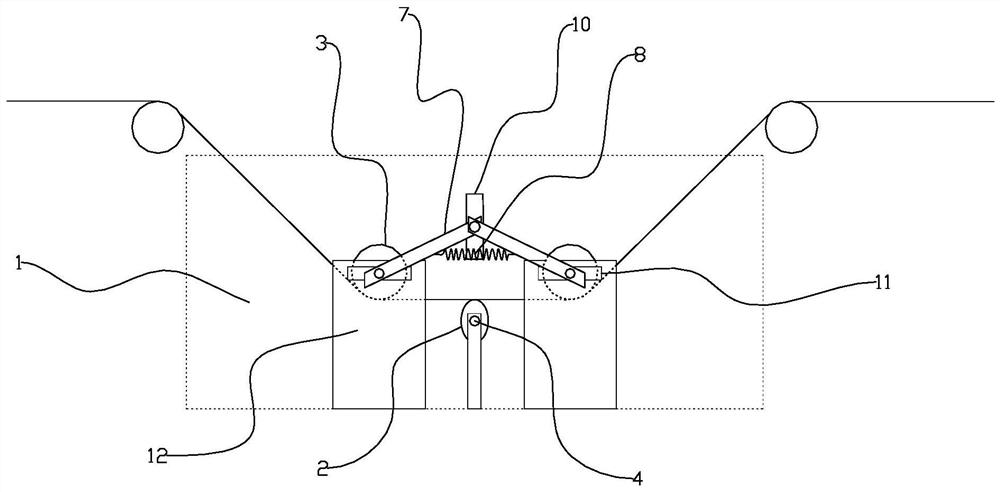

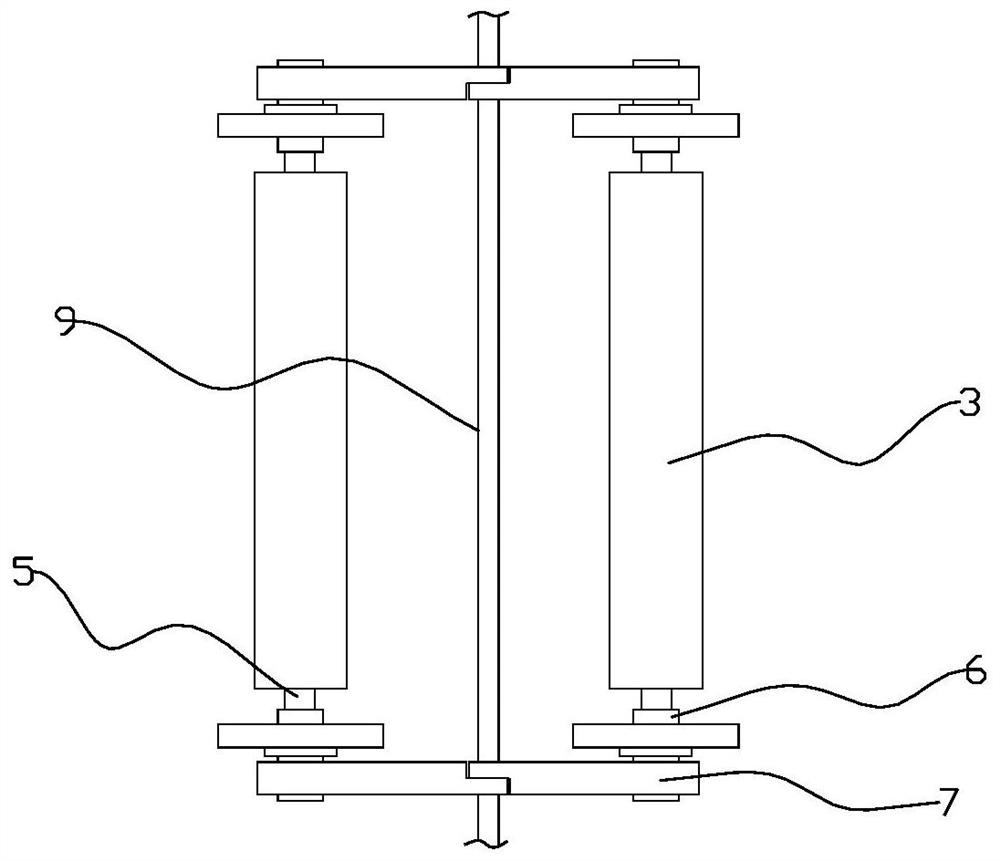

[0033] (3) Send the processed gray cloth into the dyeing pool for dyeing, wherein, please refer to figure 1 As shown, there is a defoaming roller in the middle dyeing tank to push the cloth to vibrate up and down.

[0034] Among them, singeing can be carried out in the singeing machine, mainly to remove the burrs of the gray cloth and the hair balls on the gray cloth;

[0035] Desizing is to remove the previous sizing on the warp yarns so as not to affect the dyeing. Desizing can be done with alkali desizing or enzyme desizing. The state becomes a sol state and loosens and falls off, but the stacking time is too long, which is not convenient for continuous production. Relatively speaking, enzymatic desizing can greatly increase the desizing speed without caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com