Electric spark machining device and method for three-degree-of-freedom spherical gear

A processing device and processing method technology, which is applied to electric processing equipment, attachments, metal processing equipment, etc., can solve the problems of difficult finishing of local tooth surfaces, and achieve the effects of efficient processing, simple processing path, and improved pulse utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

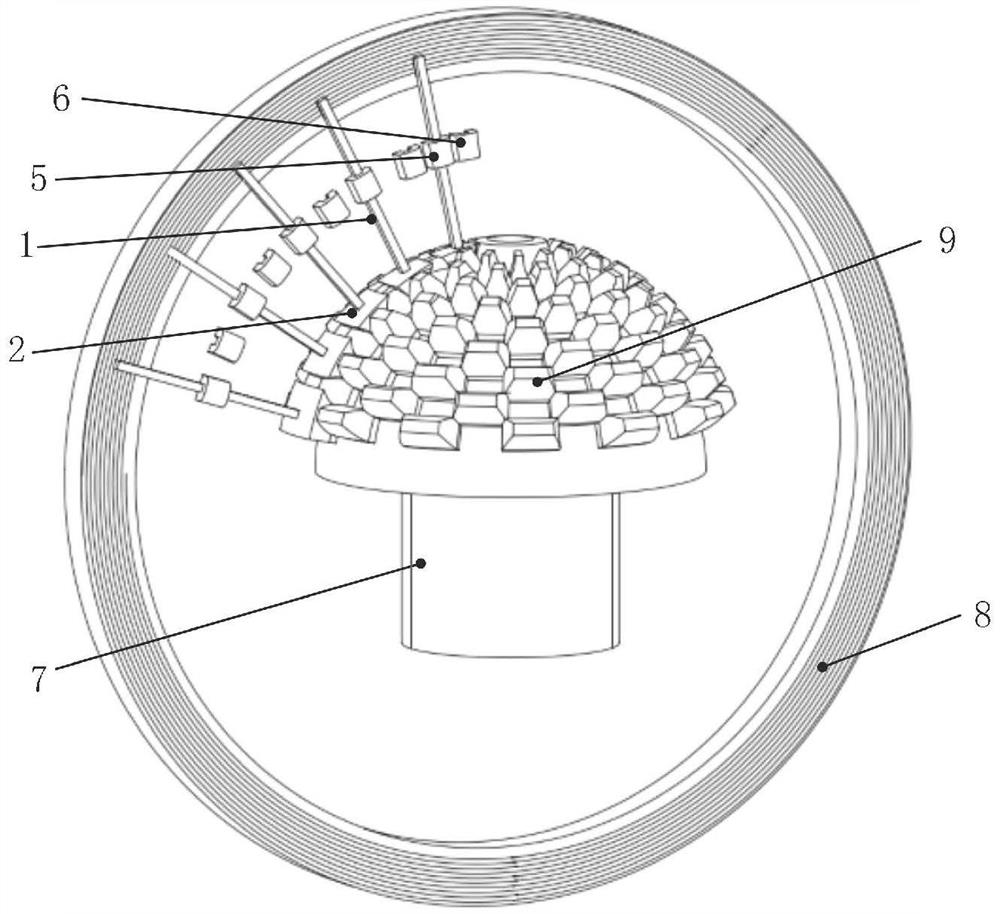

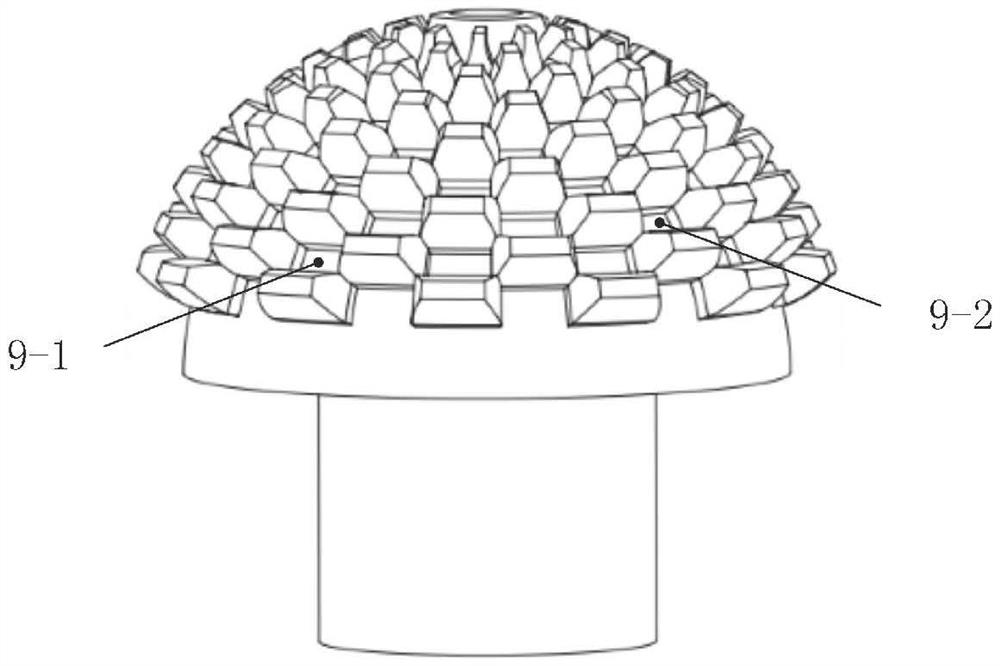

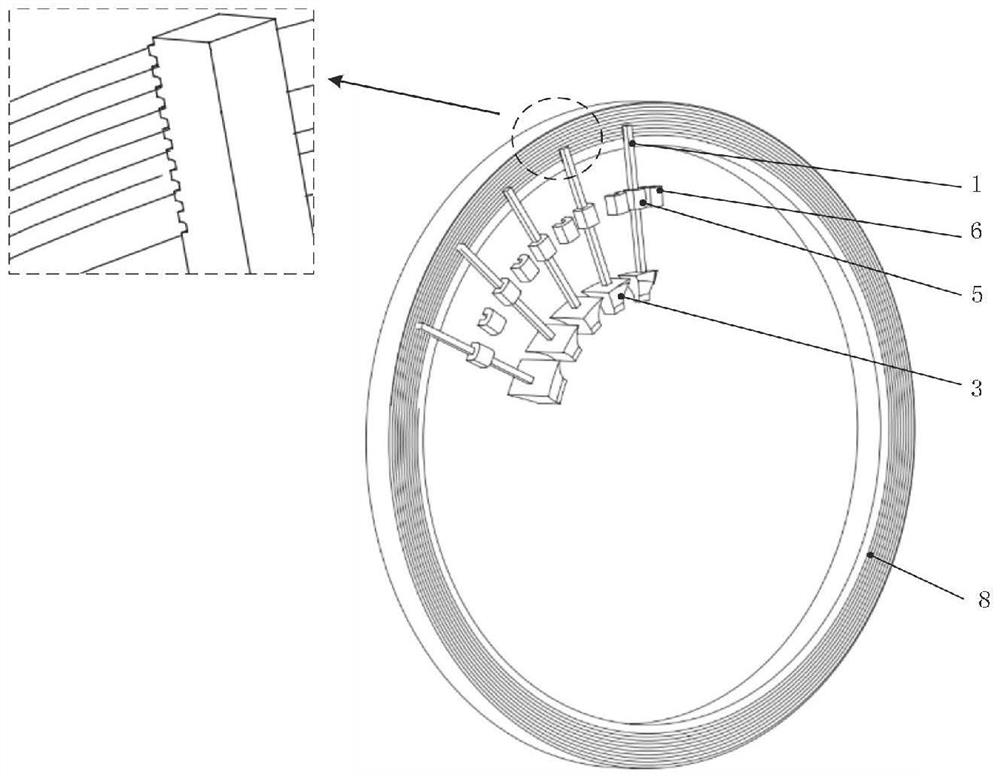

[0023] Such as Figure 1-4 As shown, a three-degree-of-freedom spherical gear electric discharge machining device includes a plurality of profiling electrode rods 1, a plurality of profiling electrode rods 2, a plurality of profiling electrode tool heads 1, and a plurality of profiling electrodes Tool head two 4, a plurality of guide grooves one 5, a plurality of guide grooves two 6, a rotating shaft 7 and a feed plate 8.

[0024] The plurality of profiling electrode rods one 1 and the plurality of profiling electrode rods two 2 have threads on their backs, and both threads can cooperate with the plane threads on the front of the feed plate 8;

[0025] The shapes of the plurality of profiling electrode tool heads 1 and the plurality of profiling electrode tool heads 2 and 4 are all different, and the plurality of profiling electrode tool heads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com