Porous carbon material with B-N Lewis acid-base pair structure as well as preparation method and application of porous carbon material

A technology of Lewis acid-base pairs and porous carbon materials, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of poor formaldehyde capture ability, poor effect, complex transformation methods, etc., and achieve good application Potential, low equipment requirements, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] In another specific embodiment, the present invention provides a method for preparing a porous carbon material based on a B-N Lewis acid-base pair structure that adsorbs formaldehyde, and the preparation method specifically includes the following steps:

[0071] Melamine, L-cysteine and boric acid are mixed and ground for 5-60min according to the mass ratio of (1-6):(1-4):(0.5-3) to obtain a solid mixture precursor, the solid mixture precursor In a tube furnace, N 2 Under the atmosphere, heat up to 500-700°C at a rate of 2-15°C / min for 1-4h, then heat up to 900-1000°C at a rate of 2-15°C / min for 1-4h, and obtain the obtained A porous carbon material based on B-N Lewis acid-base pair structure for adsorbing formaldehyde is described.

[0072] It should be clear that the adoption of the processes provided by the embodiments of the present invention or the replacement or change of conventional data all fall within the scope of protection and disclosure of the present in...

Embodiment 1

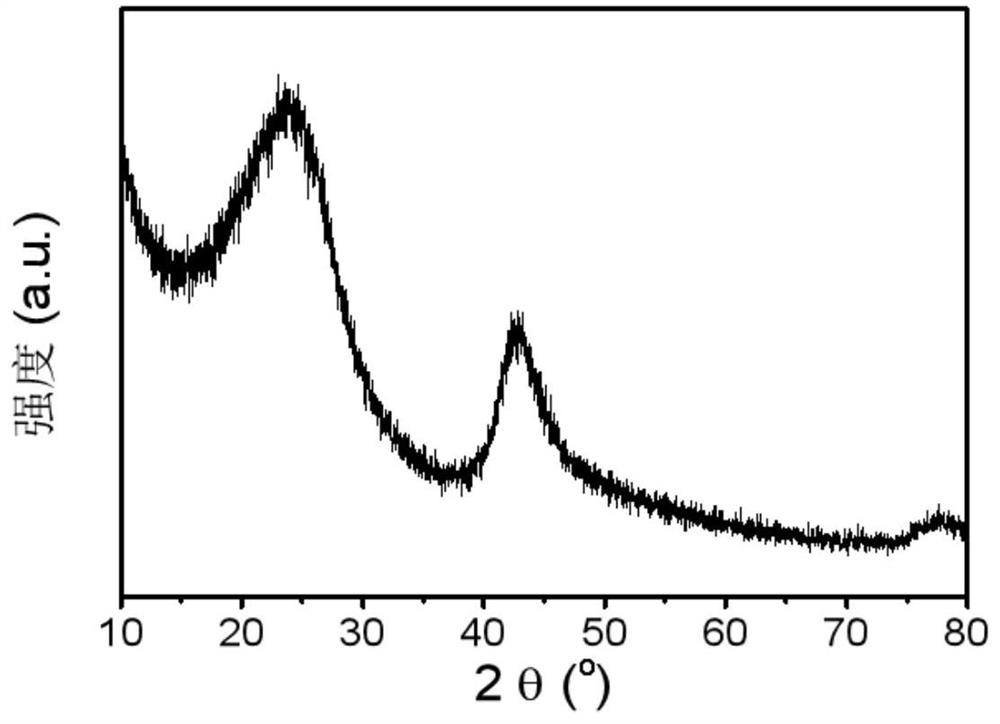

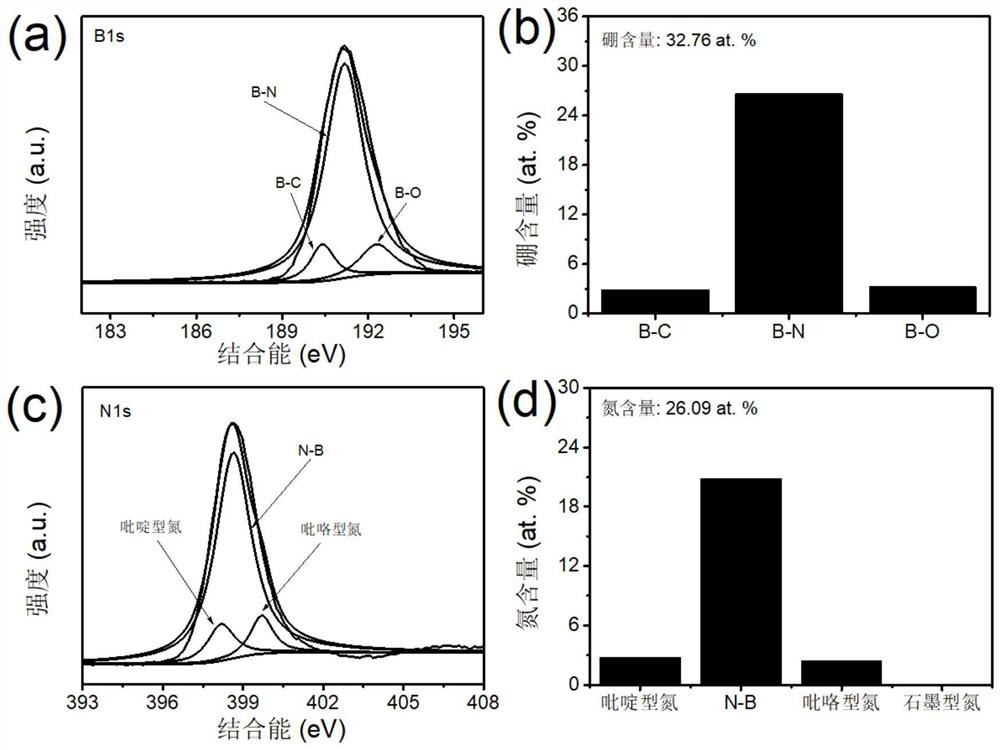

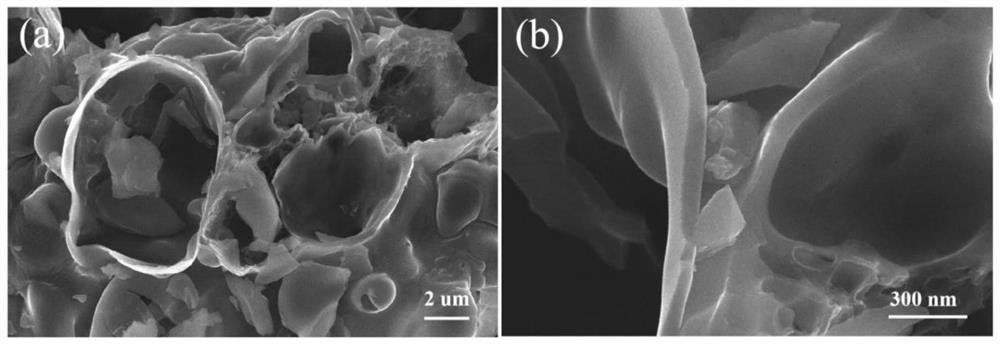

[0074] This embodiment provides a porous carbon material with a B-N Lewis acid-base pair structure, and the BET surface area of the porous carbon material is 860.2m 2 g -1 , the pore diameter range is 1-500nm, and the pore diameter is mainly concentrated at 2.0-5.0nm; the surface B content of the porous carbon material is 32.76at.%, and the N content is 26.09at.%.

[0075] This embodiment also provides a preparation method of the porous carbon material with the B-N Lewis acid-base pair structure, and the preparation method specifically includes the following steps:

[0076] Melamine, L-cysteine and boric acid are mixed according to mass ratio 2:1:1, grind 15min, obtain solid mixture precursor, described solid mixture precursor is in tube furnace, N 2 Under atmosphere, heat up to 600°C at a rate of 10°C / min and calcinate for 2 hours, then heat up to 1000°C at a rate of 10°C / min and calcinate for 2 hours, and then cool down at a rate of 10°C / min to obtain the B-N Lewis acid...

Embodiment 2

[0085] This embodiment provides a porous carbon material with a B-N Lewis acid-base pair structure. The surface B content of the porous carbon material is 28.19 at.%, and the N content is 21.31 at.%.

[0086] This embodiment also provides a preparation method of the porous carbon material with the B-N Lewis acid-base pair structure, and the preparation method specifically includes the following steps:

[0087] Melamine, L-cysteine and boric acid were mixed and ground for 15min according to the mass ratio of 4:2:1 to obtain a solid mixture precursor, and the solid mixture precursor was in a tube furnace, N 2 Under atmosphere, heat up to 600°C at a rate of 10°C / min and calcinate for 2 hours, then heat up to 1000°C at a rate of 10°C / min and calcinate for 2 hours, and then cool down at a rate of 10°C / min to obtain the B-N Lewis acid-based Alkali pair structure to adsorb formaldehyde on porous carbon materials.

[0088] Figure 8 For the X-ray diffraction spectrum of the porous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Bet surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com