Intelligent fire hydrant water pressure change monitoring system

A change monitoring and fire hydrant technology, applied in water supply devices, water outlet devices, buildings, etc., can solve the problem that monitoring probes are easy to absorb dirt or dirt, cannot realize remote and short-range alarms, and do not have water pressure monitoring functions, etc. problem, to achieve the effect of convenient viewing, simple structure and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

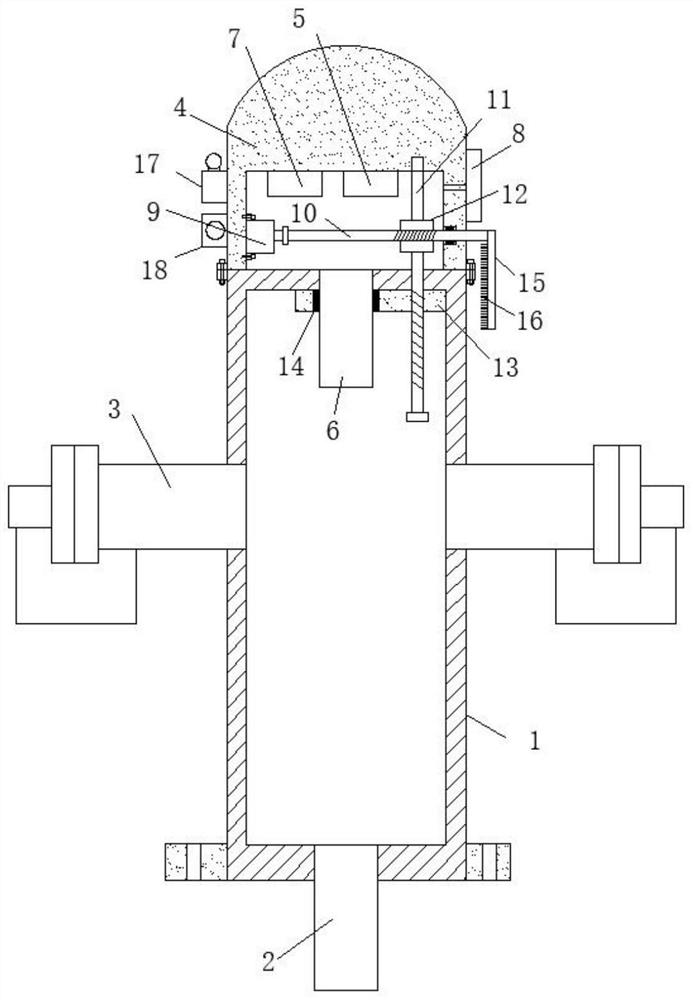

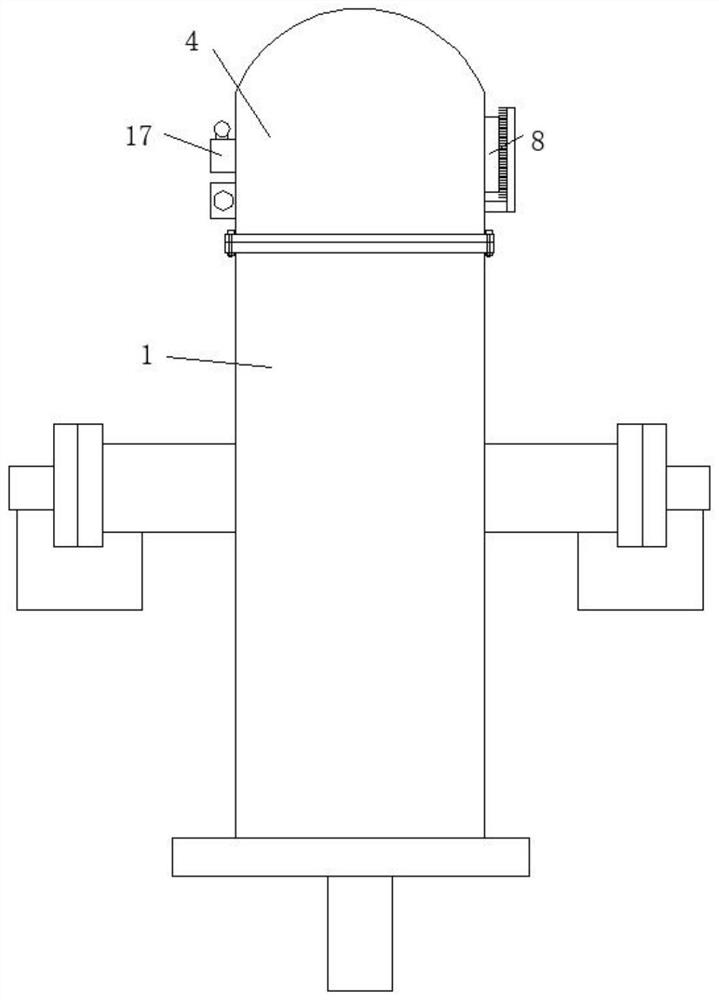

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

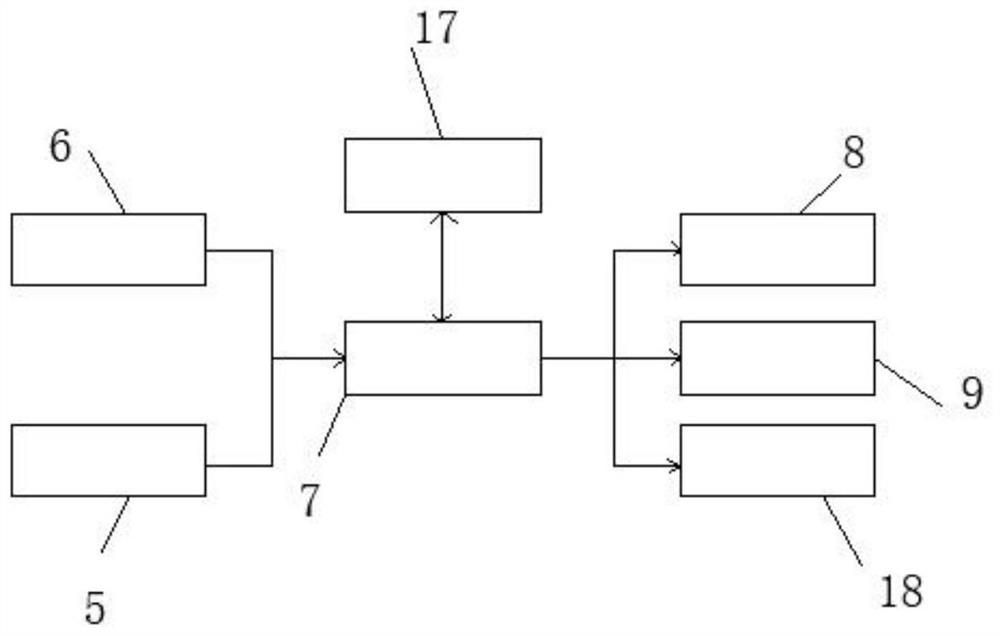

[0021] refer to Figure 1-4 , an intelligent fire hydrant water pressure change monitoring system, comprising a fire hydrant main body 1, the upper end of the fire hydrant main body 1 is fixed with a water pressure monitoring module 6 located in the fire hydrant main body 1, and the top of the fire hydrant main body 1 is detachably fixed with End cover 4, the right side of end cover 4 upper end is fixed with display module 8, the left side of end cover 4 upper end is fixed with alarm module 18 and network communication module 17, the inner side of end cover 4 is fixed with timing module 5, control module 7 and drive motor 9;

[0022] The water pressure monitoring mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com