Indwelling needle connector disinfection cap

A technology of disinfection cap and indwelling needle, which is applied in the directions of disinfection, connecting pipe, water supply device, etc., can solve the problems of misoperation, time-consuming, and inconvenient use, etc., and achieve the effect of preventing misoperation and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

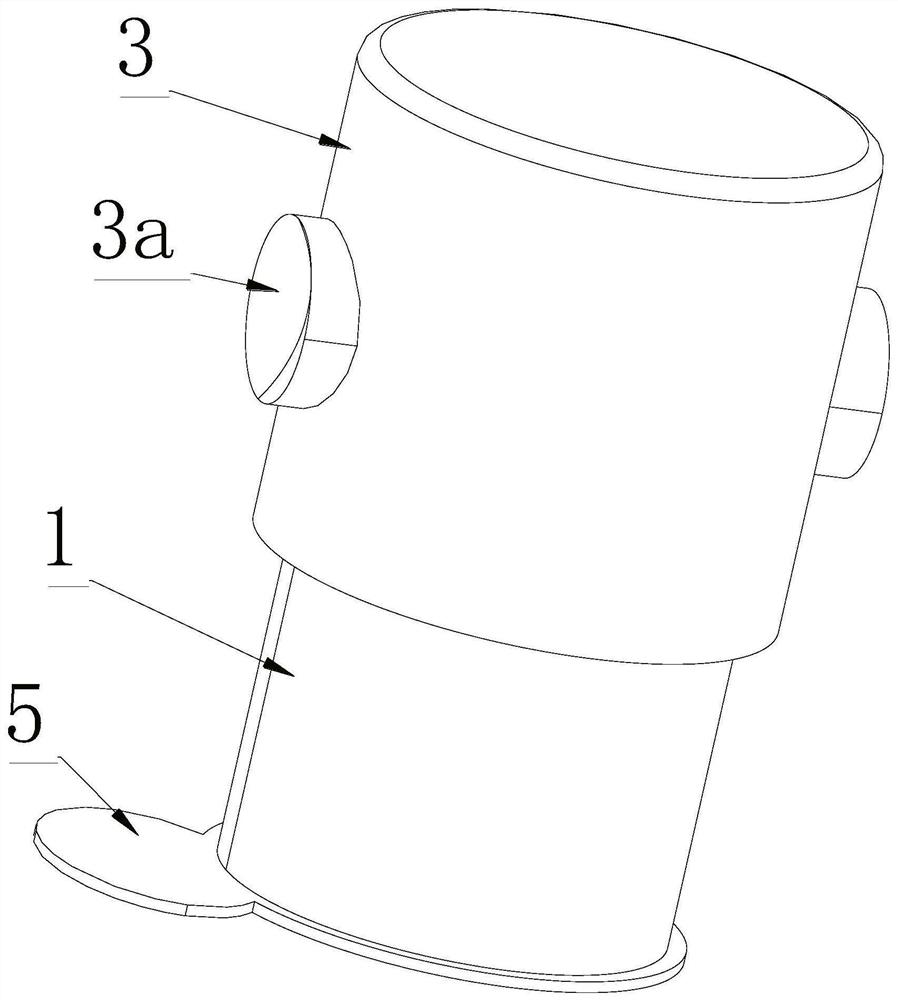

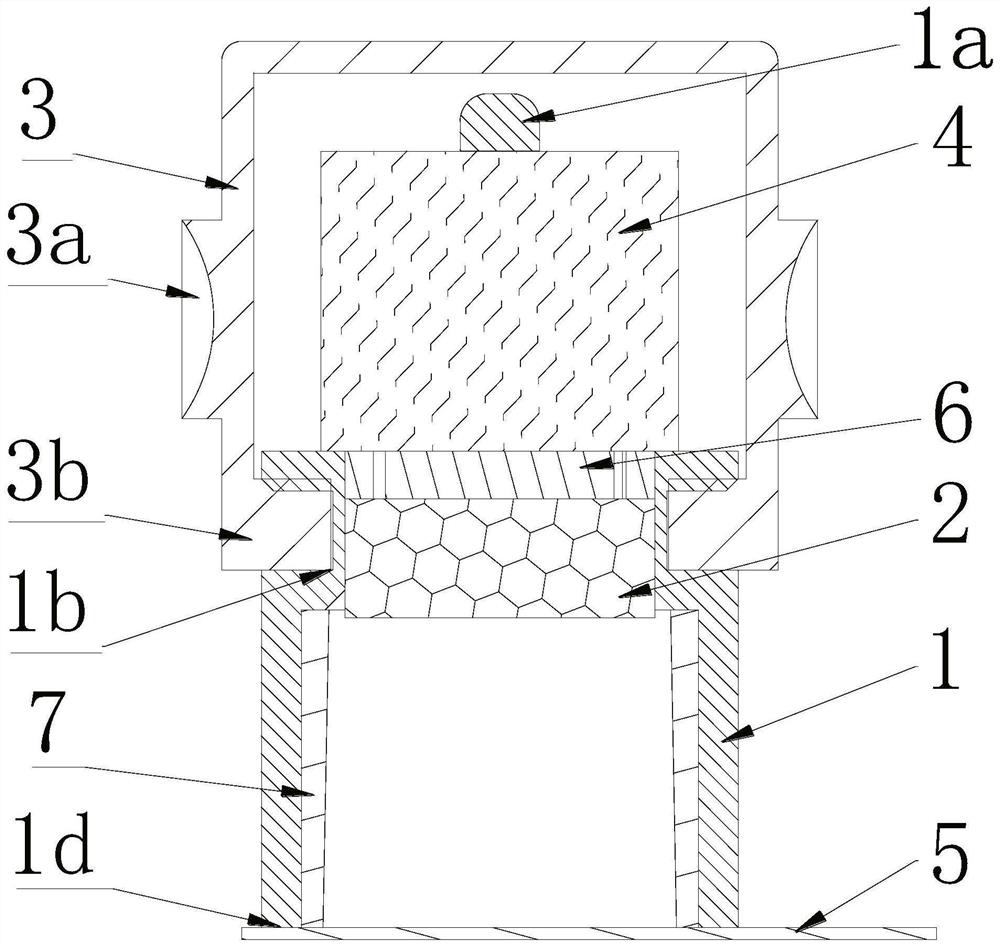

[0024] Such as Figure 1~3 As shown, an indwelling needle connector disinfection cap includes a cylindrical cap body 1, and the openings at both ends of the cap body 1 respectively form a disinfection cap mouth 1d and a disinfectant liquid outlet. The cap body 1 is provided with a disinfectant solution carrier 2 . The mouth of the disinfection cap 1d is sealed and covered with a sealing sticker 5 .

[0025] Said disinfectant liquid mouth cover of said cap body 1 is provided with extruding sleeve 3, and said extruding sleeve 3 is connected with the outer wall of said cap body 1 sealingly to form a closed extruding sleeve lumen, and said extruding sleeve lumen is Connected with the disinfectant through the mouth, the extrusion sleeve 3 has both rigidity and elasticity, which can not only maintain the shape of its inner cavity in a free state and withstand a certain extrusion force, but also deform when subjected to a large extrusion force So that its inner cavity is flattened ...

Embodiment 2

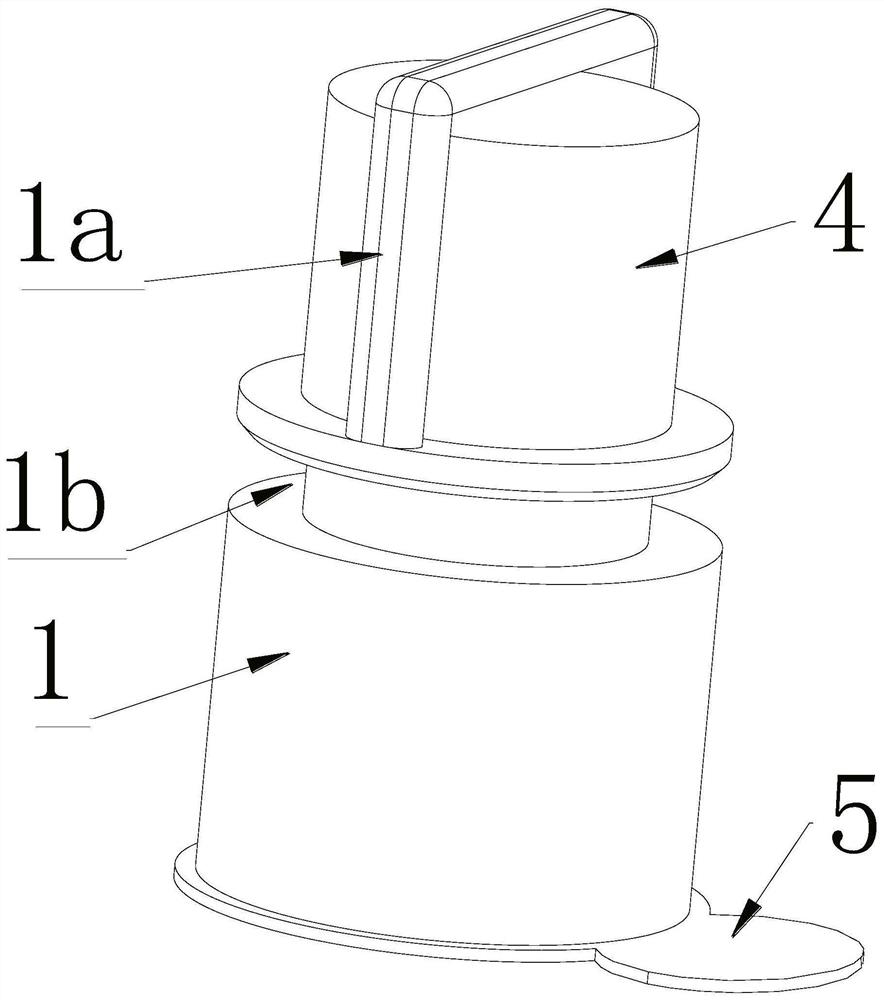

[0040] The disinfection cap structure of this embodiment is similar to Example 1, the difference is that, as Figure 4 In this embodiment, the cap body 1 is hollow cylindrical, and one end of the cap body 1 is open to form a disinfection cap opening 1d, and the center of the other end end plate 1g of the cap body 1 is provided with a disinfectant solution opening. The side is gradually inclined towards the direction of the mouth of the disinfection cap 1d from its edge to the mouth of the disinfectant to form a diversion surface 8 . The outer surface of the end plate 1g of the cap body 1 is vertically provided with a hidden twist handle 1a, and a liquid storage rod is arranged between the hidden twist handle 1a and the end plate of the cap body 1 .

[0041] An internal thread 1c is processed on the inner wall of the cap body 1 close to the disinfection cap opening 1d for sealing connection with the infusion connector with external thread.

Embodiment 3

[0043] The disinfection cap structure of this embodiment is similar to Example 1, the difference is that, as Figure 5 , The middle section of the operating twist handle 1a is integrally formed with a pressing plate 1e, and the pressing plate 1e and the cap body 1 have the same center line. The purpose of setting the pressing plate 1e is to put the cap body 1 on the infusion joint when installing the disinfection cap on the infusion joint, and then push the pressing plate 1e by hand to facilitate the installation of the cap body 1 in place.

[0044] In this embodiment, the installation method between the extrusion sleeve 3 and the cap body 1 is different from that in Embodiment 1: as Figure 6 , The middle part of the outer wall of the cap body 1 is integrally formed with a mounting ring 1f. The extrusion sleeve 3 is in the shape of a hollow cylinder with one end open, and the extrusion sleeve 3 is set outside the end where the disinfectant solution of the cap body 1 is passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com