Tea leaf fermentation device and dynamic fermentation process

A technology of tea fermentation and dynamic fermentation, which is applied in the field of tea fermentation, can solve the problems of incomplete, uneven fermentation, uneven fermentation, etc., and achieve the effects of improving production efficiency, high fermentation temperature, and high humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as Figure 1~2 As shown, the present embodiment provides a tea fermentation device, which includes a first fermentation unit 15 and a second fermentation unit 16, and the first fermentation unit 15 and the second fermentation unit 16 both include a feeder and a fermentation unit. Body 6, the first fermentation unit 15 and the second fermentation unit 16 are connected in series through a feeder, specifically, the fermentation body 6 in the first fermentation unit 15 and the fermentation body in the second fermentation unit 16 6 are connected in series through a feeder.

[0046] The feeder includes a tea conveyor belt 1 and a motor, and the motor is connected to the tea conveyor belt 1 to drive the tea conveyor belt 1 to move forward. The material opening is on the top, so that the tea leaves can be delivered to the fermentation body 6 . A uniform leaf mechanism 2 is arranged on the tea conveyor belt 1 , and the tea leaves can be evenly distributed on the tea conve...

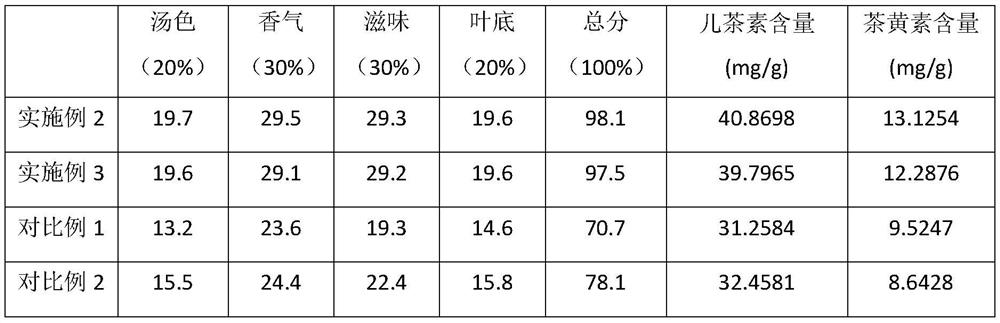

Embodiment 2

[0066] This embodiment provides a dynamic tea fermentation process using the device of Embodiment 1, comprising the following steps:

[0067] S1. The spring buds and leaves of a tea garden in Wuyuan in late March 2021 are used as raw materials. The fermentation temperature in the first fermentation room is 33°C, the fermentation humidity is 90%, and the fermentation time is 2.5 hours;

[0068]S2, the time of transporting the tealeaves after the first fermentation on the feeding machine is 4 minutes;

[0069] S3. The fermentation temperature of the spring tea after the first fermentation in the second fermentation chamber is 29°C, the fermentation humidity is 87%, the fermentation time is 1.5h, and the fermentation is completed.

Embodiment 3

[0071] This embodiment provides a dynamic tea fermentation process using the device of Embodiment 1, comprising the following steps:

[0072] S1. Using summer buds and leaves from a tea garden in Wuyuan in late May 2021 as raw material, the fermentation temperature of summer tea in the first fermentation room is 31°C, the fermentation humidity is 88%, and the fermentation time is 2 hours;

[0073] S2, the time for conveying the tealeaves after the first fermentation on the feeding machine is 5 minutes;

[0074] S3. The fermentation temperature of the summer tea after the first fermentation in the second fermentation chamber is 28° C., the fermentation humidity is 85%, and the fermentation time is 1 hour and 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com