Active noise reduction device and range hood

An active noise reduction and noise reduction technology, applied in active noise control, oil fume removal, lighting and heating equipment, etc., can solve problems such as oil accumulation and affecting noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

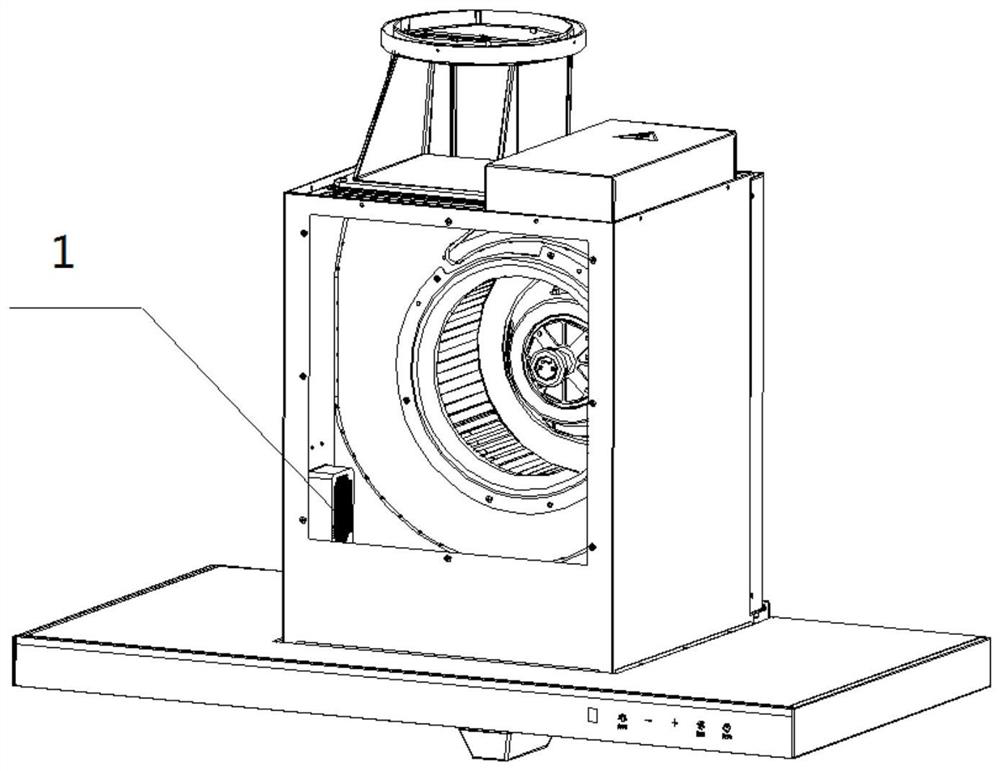

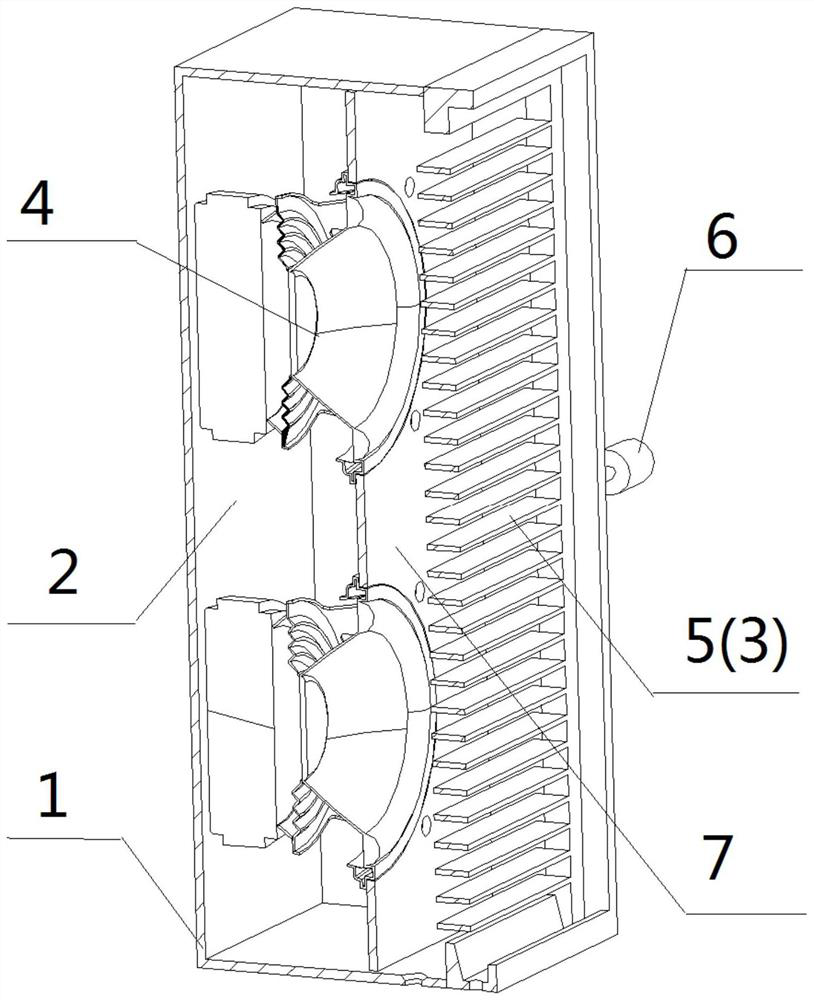

[0045] Such as figure 1 - image 3 , the present embodiment provides an active noise reduction device, including: a housing 1, a dust collecting part and a noise reducing part.

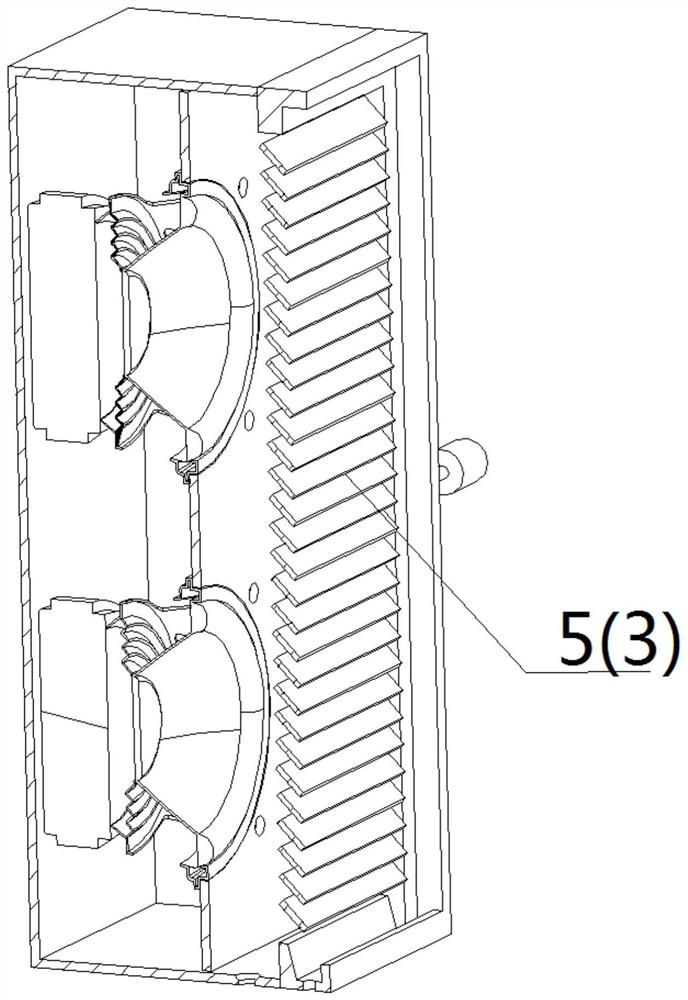

[0046] The housing 1 is arranged in a square shape, with a housing chamber 2 inside the package, and an opening 3 is provided on one side of the housing chamber 2. The position of the opening 3 is not limited, and can be arranged on the top side or the bottom side of the housing 1. As a preferred embodiment, The opening 3 is arranged on the side wall of the housing chamber 2 , and at the same time, the opening 3 is arranged in a square shape, which is convenient for the subsequent installation and operation of the electrode plate 5 .

[0047] The dust collection part is set on the opening 3, including several electrode plates 5, the electrode plates 5 are connected to the external power supply through the power cord, after the power is turned on, the electrode plates 5 are charged with static electrici...

Embodiment 2

[0065] On the basis of Embodiment 1, in this embodiment, the electrode plate 5 is not completely a conductor, and its two sides are an adsorption surface and an insulating surface, wherein the adsorption surface is arranged as a conductor, which is suitable for adsorbing dirt particles on the surrounding side. It is an insulating surface, which is set as an insulator. In the closed state, the adsorption surface is set towards the outside of the opening 3, and the insulating surface is set towards the inside of the opening 3.

[0066] By being provided with an insulator on one side of the electrode plate 5, avoiding the adsorption of greasy dirt, so that the side adsorption surface of the greasy dirt is adhered on the electrode plate 5, and faces the outside of the opening 3 when in the closed state, so that the greasy dirt adhering to the electrode plate 5 It can fall to the outside of the housing 1 or into the oil holding chamber, avoiding entering the housing 1 and affecting ...

Embodiment 3

[0068] Such as Figure 4 - Figure 5 As shown, on the basis of Embodiment 1, in this embodiment, an outer pole plate 8 is provided outside the opening 3, and a number of sound passing holes are evenly arranged on it, and the setting of the sound passing holes can be used for collecting or The emitted sound waves pass through, and at the same time endow the particles or dust flowing through the sound hole with the same electrical properties as the outer plate 8 itself, and at the same time, the two sides of the electrode plates 5 have different electrical properties, so that each electrode plate 5 exists Single side for dust absorption. In this embodiment, the opposite sides of the electrode plate 5 and the outer electrode plate 8 are electrically opposite.

[0069] By setting the outer pole plate 8, the side of the electrode plate 5 facing the outside of the opening attracts dust and dirt with different charges, avoiding the side of the accommodating cavity from absorbing oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com