Steel wire rope cabin penetrating sealing device and method

A sealing device and wire rope technology, which is applied in the field of piercing and sealing, can solve the problems of wire rope wear, low service life, and the wire rope cannot provide buffering, etc., and achieve the effects of increasing volume, quick installation and disassembly, and tight sealing connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]At present, there are many kinds of submarine cable penetration sealing structures, but they are generally used in shallow sea areas. Among them, the most common way is to fix the submarine cable by clamping the armored steel wire with the inner and outer cones, and seal it with the sealing ring. This method can withstand tension, but not axial pressure.

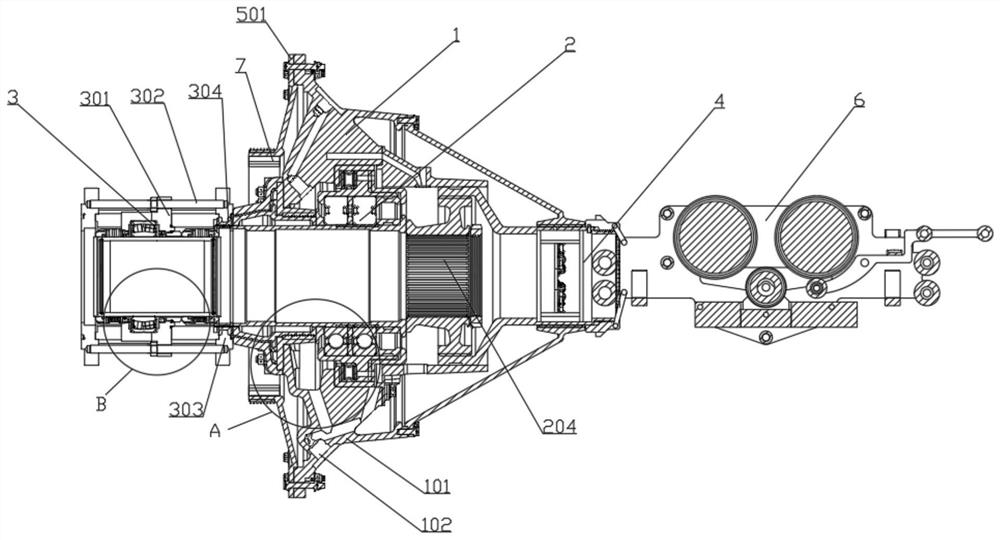

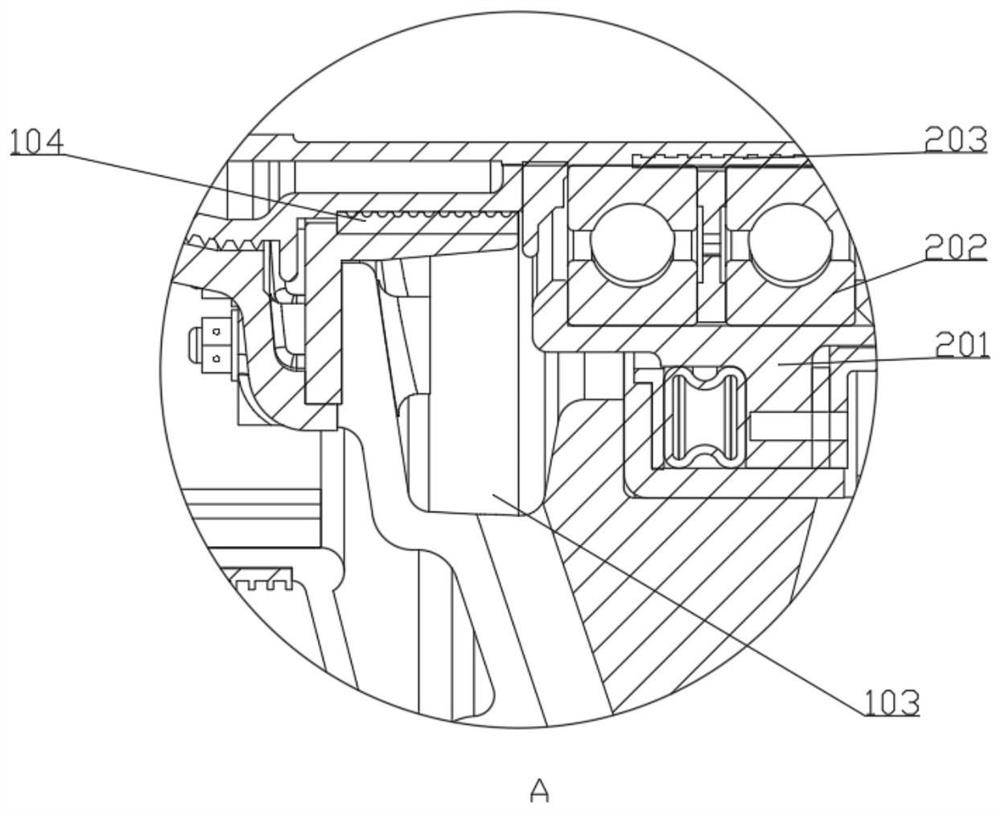

[0042] Such as Figure 1-6 As shown, the present invention provides a steel wire rope penetration sealing device, which includes a penetration portion 1, a transfer portion 3, a fastening guide portion 4 and a plurality of sealing portions 7, and the fastening guide portion 4 is placed at the front end of the penetration portion 1 , the piercing part 1 includes a housing 101, an oil filling port 102, a lubrication chamber 103 and a sealing ring 104, the oil filling port 102 is placed on the side of the housing 101, the lubrication warehouse 103 is placed inside the housing 101, the oil filling port 102 and the lubrica...

Embodiment 2

[0051] At present, there are many kinds of submarine cable penetration sealing structures, but they are generally used in shallow sea areas. Among them, the most common way is to fix the submarine cable by clamping the armored steel wire with the inner and outer cones, and seal it with the sealing ring. This method can withstand tension, but not axial pressure.

[0052] Such as Figure 1-6 As shown, the present invention provides a steel wire rope penetration sealing device, which includes a penetration portion 1, a transfer portion 3, a fastening guide portion 4 and a plurality of sealing portions 7, and the fastening guide portion 4 is placed at the front end of the penetration portion 1 , the piercing part 1 includes a housing 101, an oil filling port 102, a lubrication chamber 103 and a sealing ring 104, the oil filling port 102 is placed on the side of the housing 101, the lubrication warehouse 103 is placed inside the housing 101, the oil filling port 102 and the lubric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com