Oilless air compressor with circulating cooling function

An oil-free air compressor and circulating cooling technology, which is applied to the control mechanism of the wing fan, mechanical equipment, power control mechanism, etc., can solve the problems of limited heat dissipation and easy damage of the cooling fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

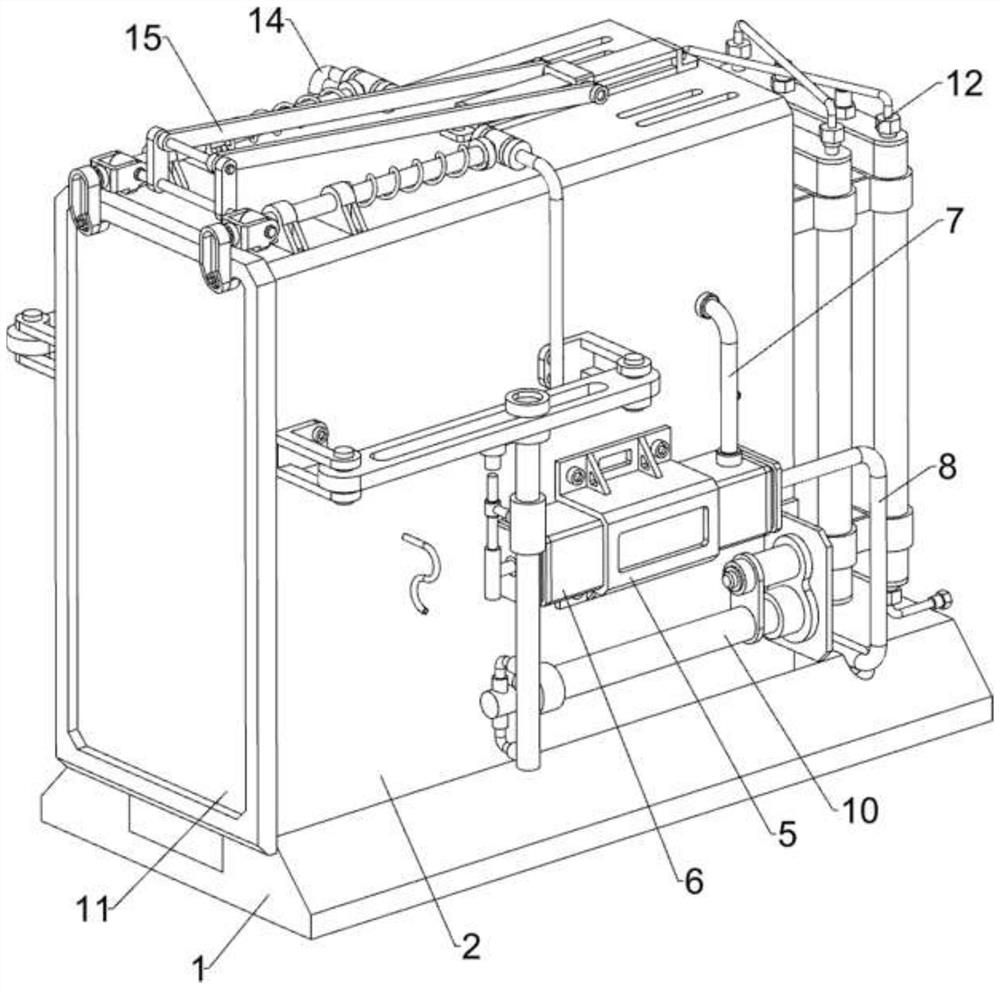

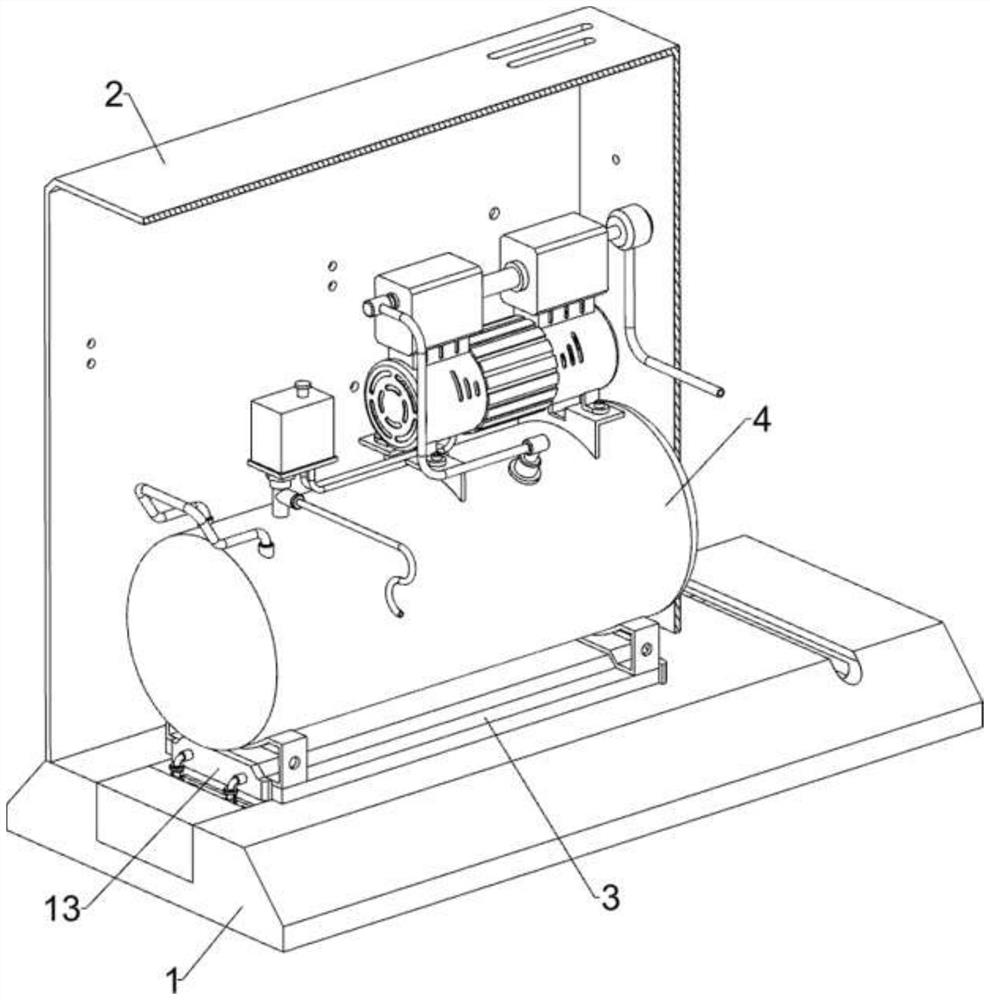

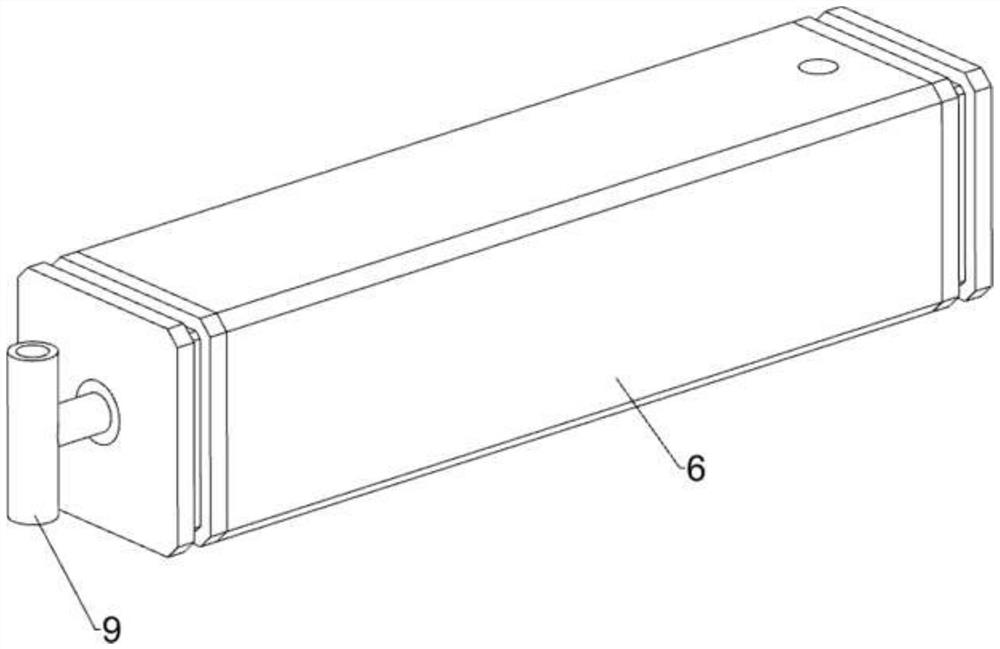

[0035] An oil-free air compressor with circulating cooling function, such as Figure 1-7 As shown, it includes a base 1, a housing 2, a guide block 3, an air compressor 4, a fixed frame 5, a cylinder body 6, an air outlet pipe 7, an air suction pipe 8, a piston rod 9, a push assembly 10 and a cover assembly 11, There is a groove on the left side of the base 1, a housing 2 is provided on the top of the base 1, four through holes are opened on the right side of the top of the housing 2, and the through holes are used for heat dissipation, and a guide block 3 is welded on the left side of the top of the base 1, and the guide block 3 is located in the housing 2, and the air compressor 4 is slidingly installed on the guide block 3, and the lower and right sides of the front and rear sides of the housing 2 are fixed with a fixed frame 5 by bolts, and a cylinder body 6 is set inside the fixed frame 5 , the air outlet pipe 7 is connected between the right side of the top of the cylind...

Embodiment 2

[0042] On the basis of Example 1, such as figure 1 , figure 2 , Figure 4 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, cooling assembly 12 is also included, and cooling assembly 12 can produce cold air. Vent pipe 128, the upper and lower sides on the right side of housing 2 are all connected with support plates 121 by bolts, two processing frames 122 are arranged between the upper and lower support plates 121, and the suction pipe 8 is connected with the processing frame 122 of the inner side. The bottom is connected, and the front and rear sides of the outer processing frame 122 are provided with air intake pipes 123, and the processing frame 122 is provided with cooling pipes 124, which are used to make cold air, and the outer processing frame 122 is provided with water inlet pipes at the bottom and front side 125, the water inlet pipe 125 is connected to the cooling pipe 124 on the outside, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com