Full-automatic datamation constant-tension tailing-free automatic roll changing and unwinding control system

A control system and data-based technology, applied in thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problem that the feeding and unwinding tension cannot be kept constant, and achieve the effect of avoiding material breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

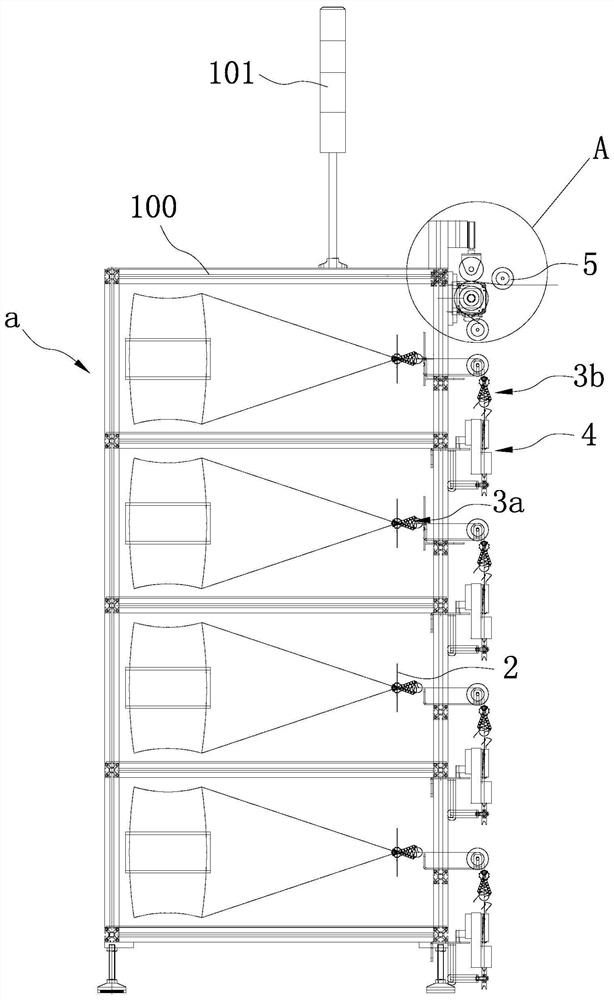

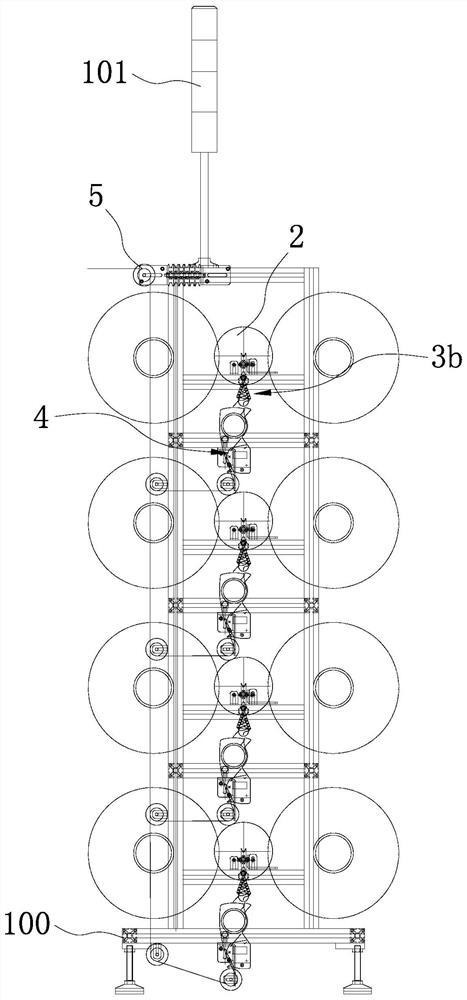

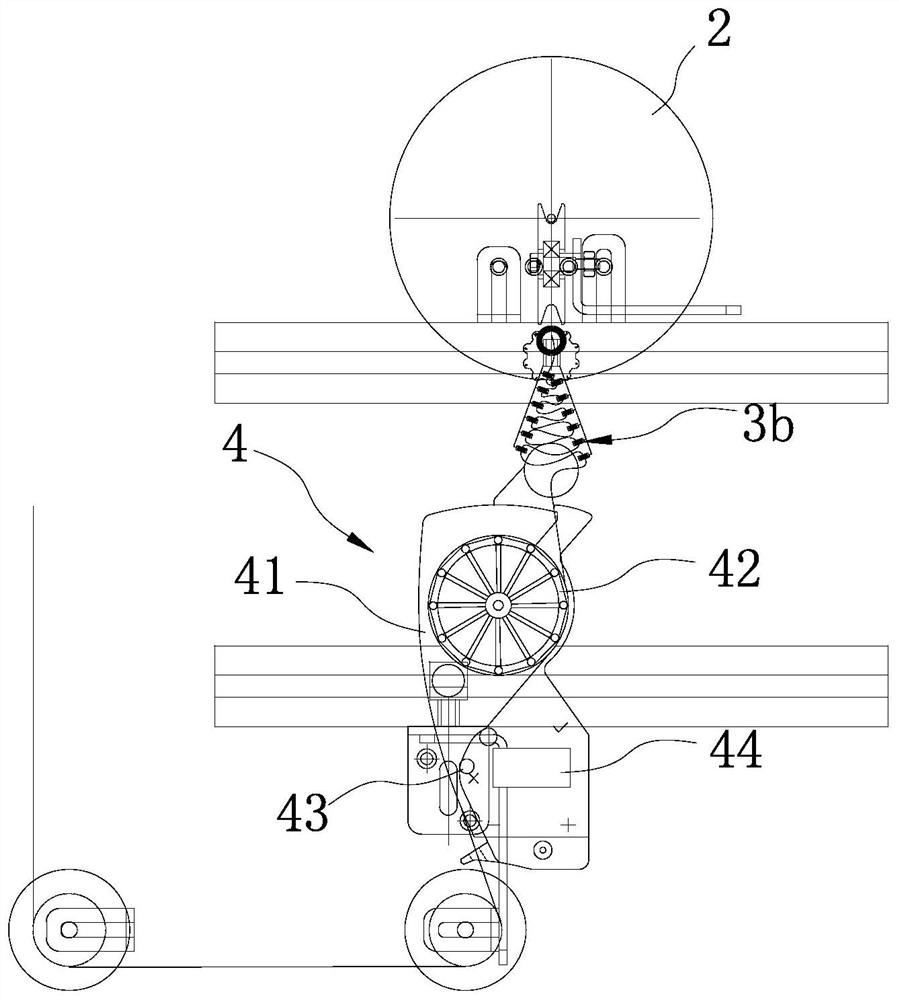

[0034] refer to Figure 1 to Figure 7 , a fully automatic data-based constant tension and tailless automatic roll changing and unwinding control system, including a frame 100, and four feeding stations a are stacked on the frame 100, and the number of feeding stations a can be determined according to requirements And change increase and decrease, on each described feeding station a, be provided with two symmetrically arranged hanging racks 1 for placing material rolls, according to the feeding process of the elastic, the feeding station a is successively provided with a yarn retaining plate 2, The primary buffer mechanism 3a, the secondary buffer mechanism 3b, the digitized elastic force control mechanism 4 and a number of guide wheels for guiding each component are arranged on the frame 100 at the delivery rear end of the digitized elastic force control mechanism 4 for Gather the outlet guide wheel group 5 of the rubber bands conveyed on each feeding station a;

[0035] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com