Three-dimensional packaging machine for transparent film

A transparent film and packaging machine technology, applied in the direction of packaging machines, packaging, transportation packaging, etc., can solve the problems of troublesome feeding of roll film and composite unsealing line, complicated processing of machine parts, and inconvenient assembly of the main platform, etc., to achieve improved Review the effects of efficiency and management convenience, convenient installation and positioning, and convenient and quick modular assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

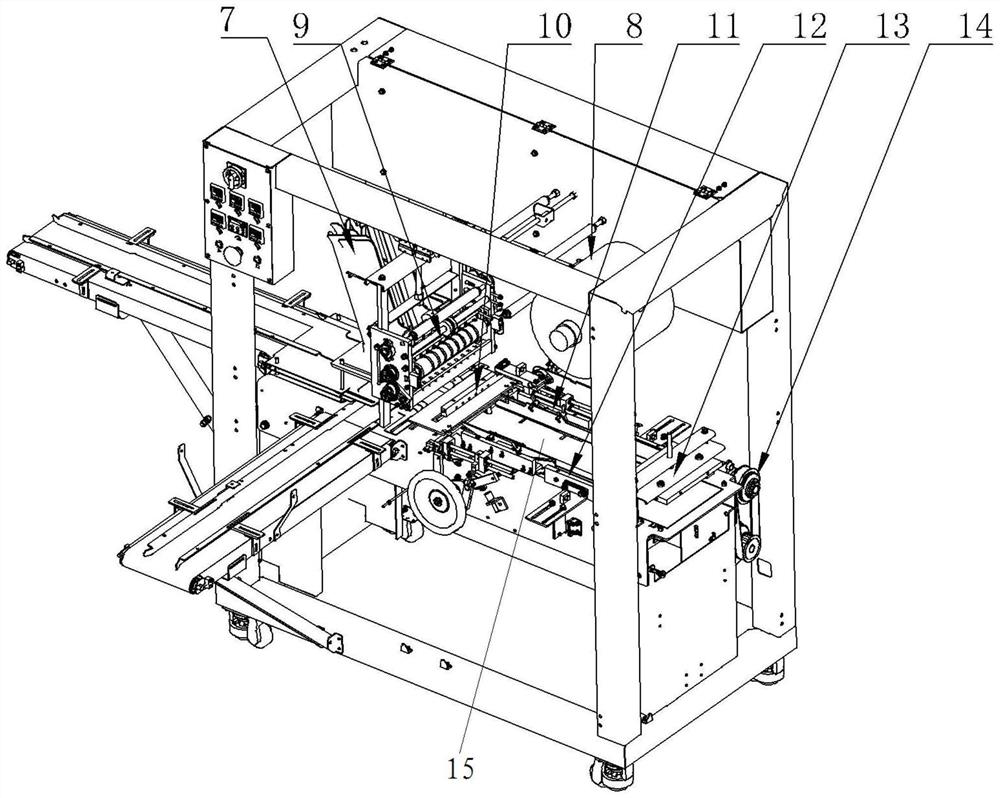

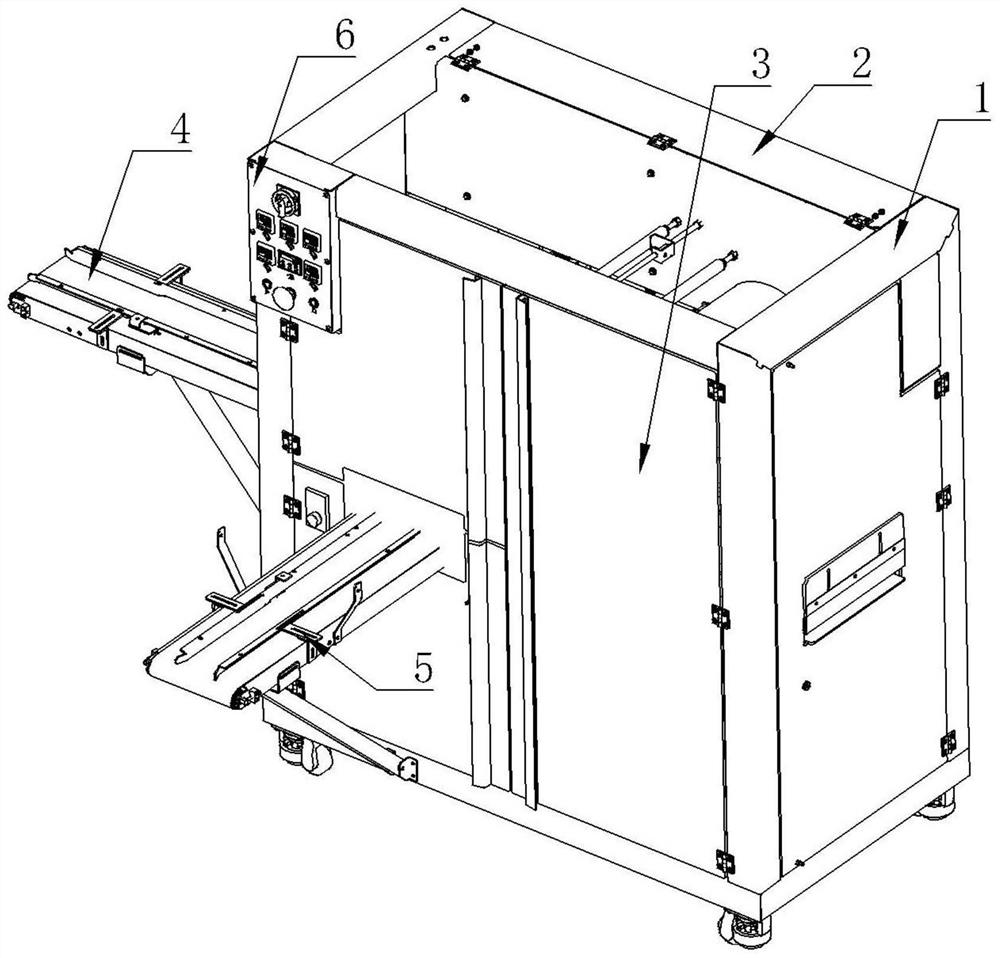

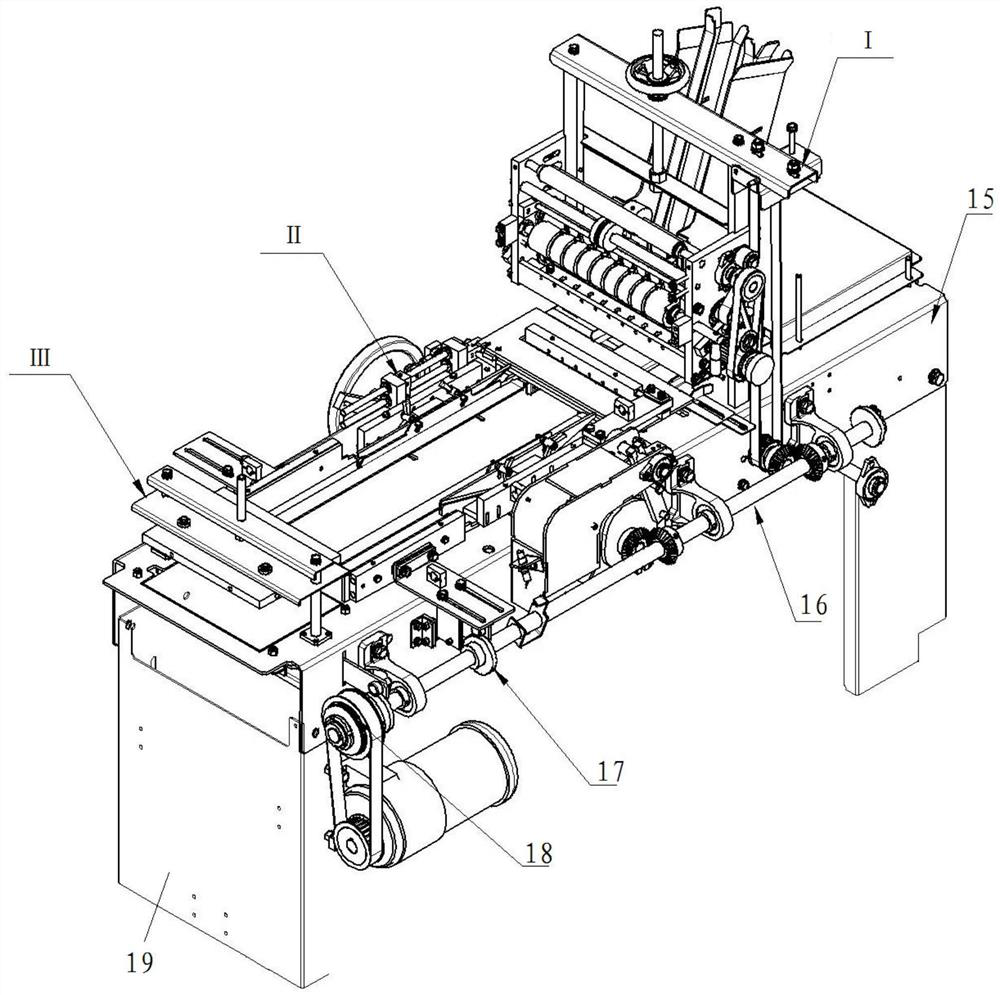

[0033] see Figure 1-2 , the transparent film three-dimensional packaging machine of the present embodiment includes the following parts:

[0034] Frame 1, car tailgate electrical box 2, acrylic door 3, straight feed conveyor 4 / forward feed conveyor 5 / manual unloading hopper 7, operation panel 6, film release and compound wire removal mechanism 8, film cutting mechanism 9, Long sealing mechanism 10 , hemming mechanism 11 , side sealing mechanism 12 , shaping mechanism 13 , main transmission shaft part 14 .

[0035] The frame 1 is welded with square tubes, the operation box is located in the upper left corner of the frame, and it can be used as a column to install the operation panel, which saves observation space. The switch of the car tailgate type electric box 2 is convenient and saves space;

[0036] There are all transparent acrylic doors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com