Automatic packaging equipment and packaging method for building boards

A technology of automatic packaging and building boards, applied in packaging and other directions, can solve the problems of inability to achieve independent palletizing, insufficient improvement of board packaging efficiency, and interruption of continuous packaging of boards, so as to achieve the effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

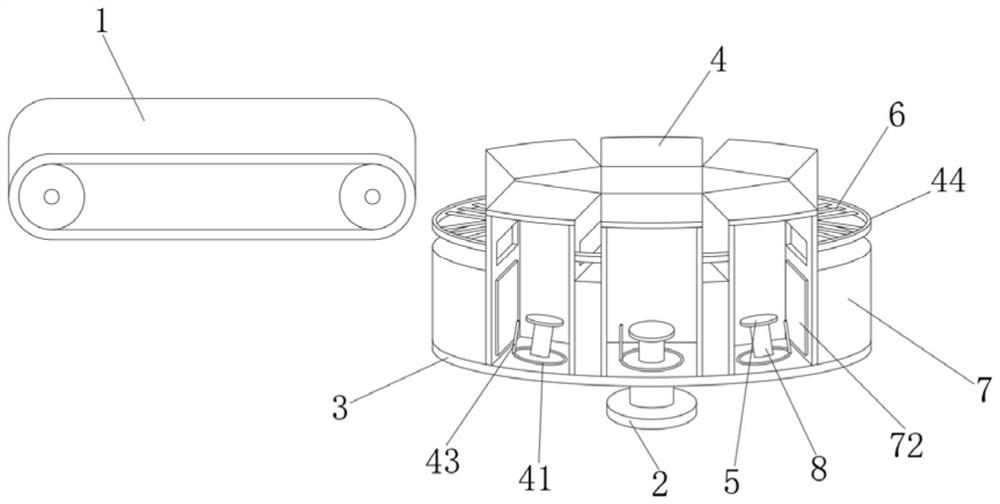

[0027] see Figure 1-7 , this embodiment provides an automatic packaging equipment for building boards, including a conveyor belt 1 for transporting boards, one end of the conveyor belt 1 is connected to the board production equipment and processing equipment, and the other end is facing the turntable 3, and the turntable 3 can make temporary The storage bin 4 is in turn facing the end of the conveyor belt 1 , and the plates can be transported to the interior of the temporary storage bin 4 one by one by the conveyor belt 1 .

[0028] In order to realize the rotation of the turntable 3, the end of the conveyor belt 1 is provided with a fixed pile 2, and the top surface of the fixed pile 2 is rotatably connected with the turntable 3 through a rotating shaft.

[0029] Among them, in order to make the rotation of the turntable 3 more stable, a servo motor is installed on the top surface of the fixed pile 2 close to the center of the circle. Power rod 21, the end of power rod 21 a...

Embodiment 2

[0042] see figure 2 , on the basis of Embodiment 1, a further improvement is made: after the temporary storage bin 4 and the conveyor belt 1 are successively facing each other, the stability and accuracy of sheet material transmission are ensured.

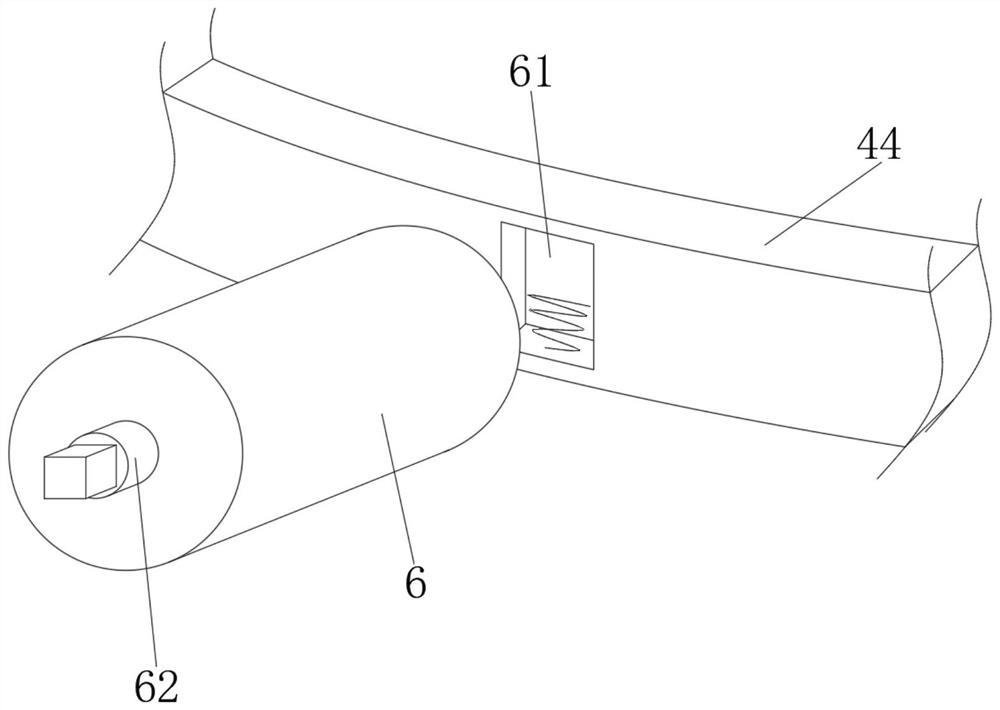

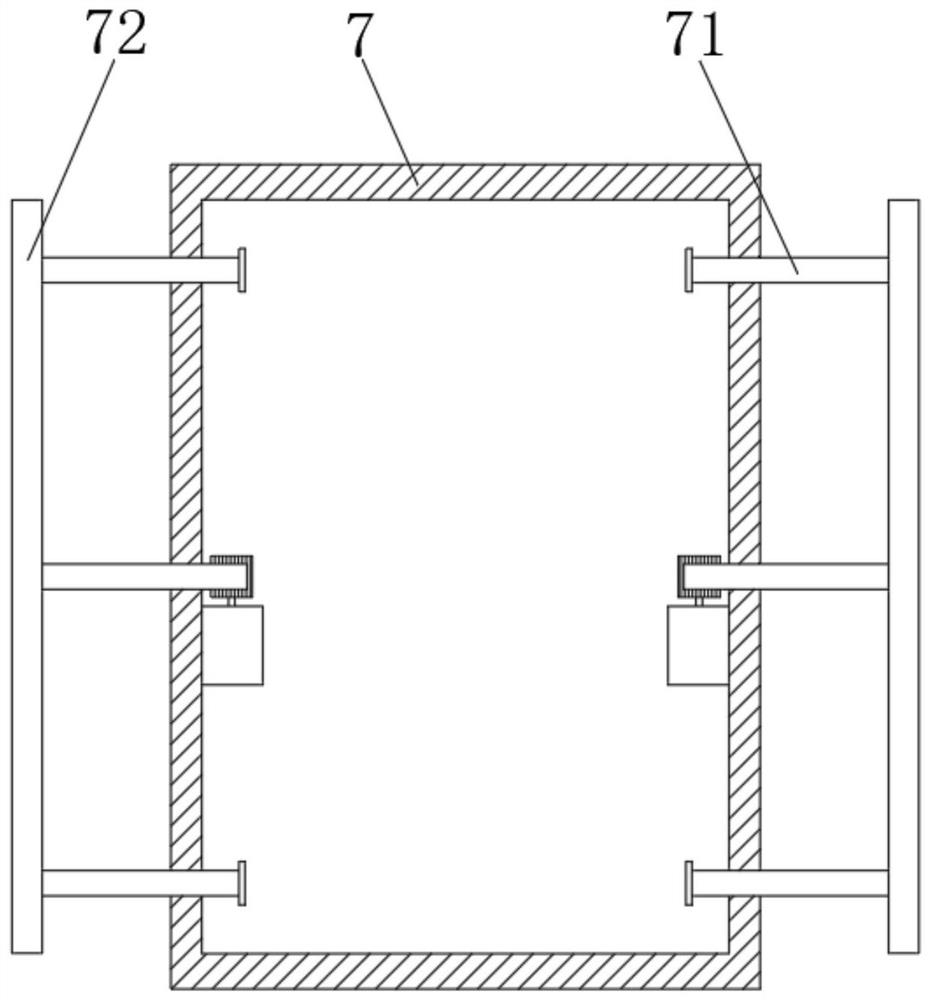

[0043] Preferably, a plurality of transmission rollers 6 are installed between adjacent temporary storage bins 4 through a connecting frame 44, and a plurality of transmission rollers 6 are connected by a chain, the transmission rollers 6 can rotate synchronously, and the side of the connecting frame 44 is installed with The motor powered by the conveying roller 6 can change the direction of rotation of the conveying roller 6, so as to realize the transmission of the plates in two directions, and then when the temporary storage bin 4 is changed, it will not cause the plate to be transported and packaged. interruption.

[0044] In order to reduce the impact force between the plate and the conveying roller 6, a chute 61 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com