Corn cob positioning robot arm for corn seed testing

A technology of corn cob and robot hand, applied in the direction of manipulator, claw arm, chuck, etc., can solve the problems of inability to meet requirements, slow speed, affecting photography, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

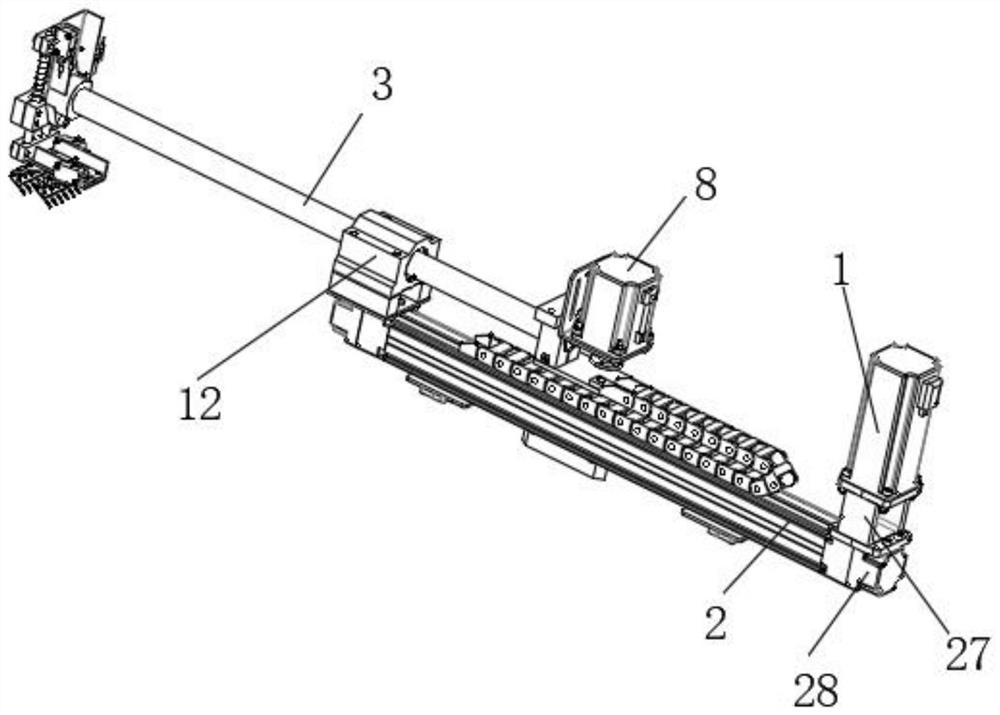

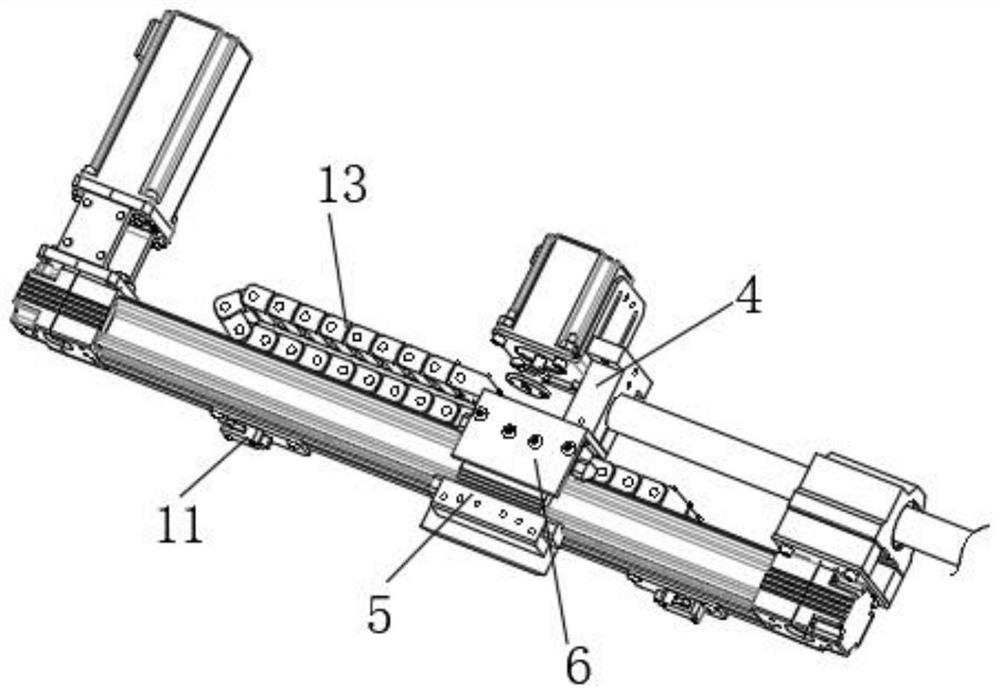

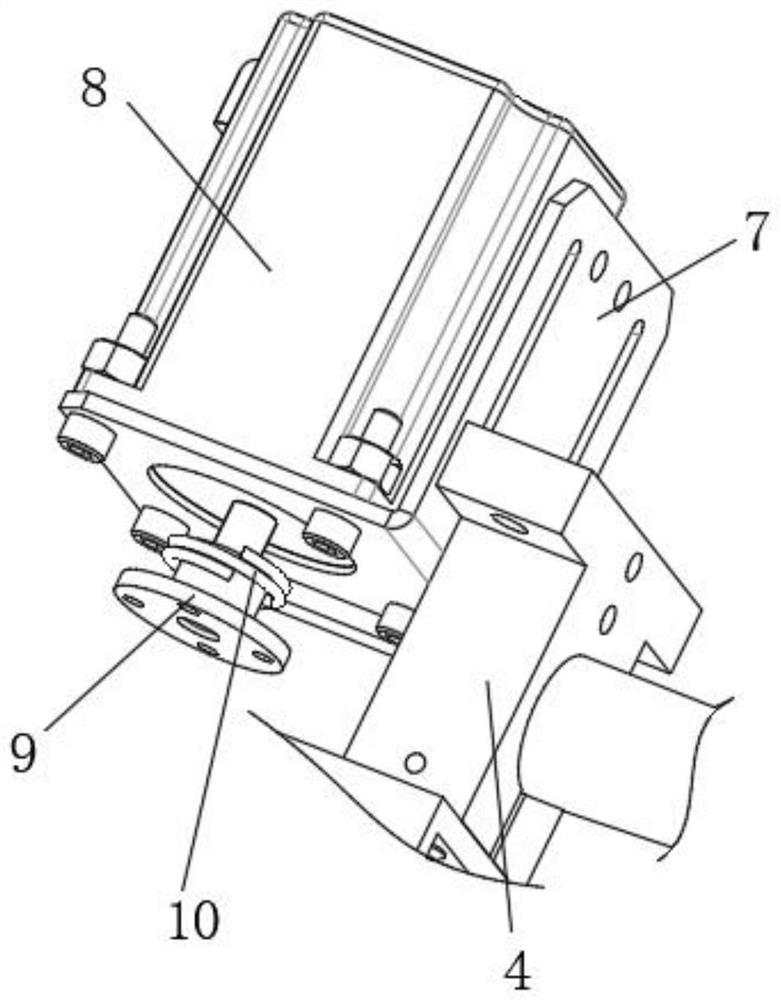

[0025] refer to Figure 1-6 , a corn cob positioning robot hand for corn seed testing, including a horizontally driven stepping motor 1, a slide rail 2 is provided below the horizontally driven stepping motor 1, and a motor is installed between the slide rail 2 and the horizontally driven stepping motor 1 Both ends of the bracket 27 and the slide rail 2 are equipped with a rear cover 28, the slide rail 2 is provided with a linear bearing 12, the linear bearing 12 is provided with a hollow optical shaft 3, and the slide rail 2 is provided with an optical shaft T-shaped sleeve 4, One end of the hollow optical axis 3 is installed on the optical axis T-shaped sleeve 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com