Assembling equipment and method for assembling flat cables on earphone shells

A technology for assembling equipment and assembling devices, applied in the field of headphones, can solve the problems of increasing waiting time, unstable product quality, and increasing labor costs, and achieve the effects of reducing waiting time consumption, shortening production takt, and improving installation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

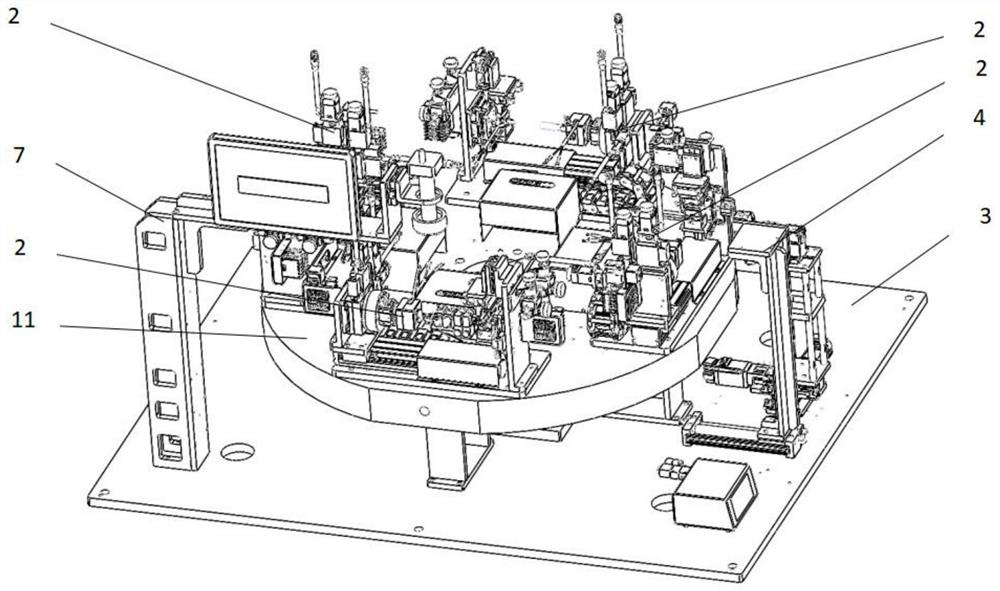

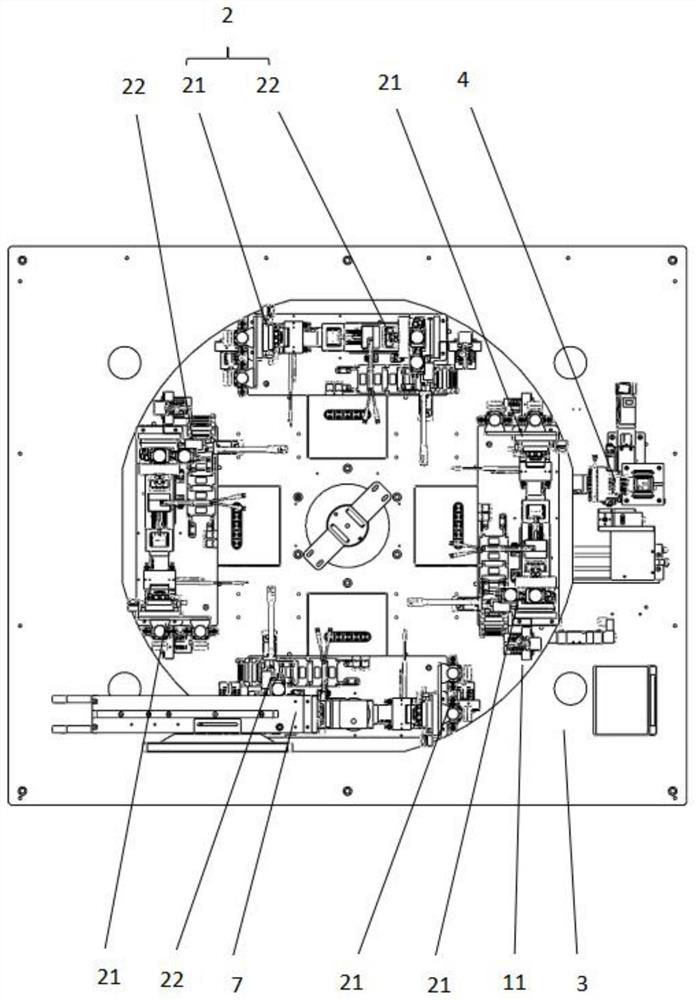

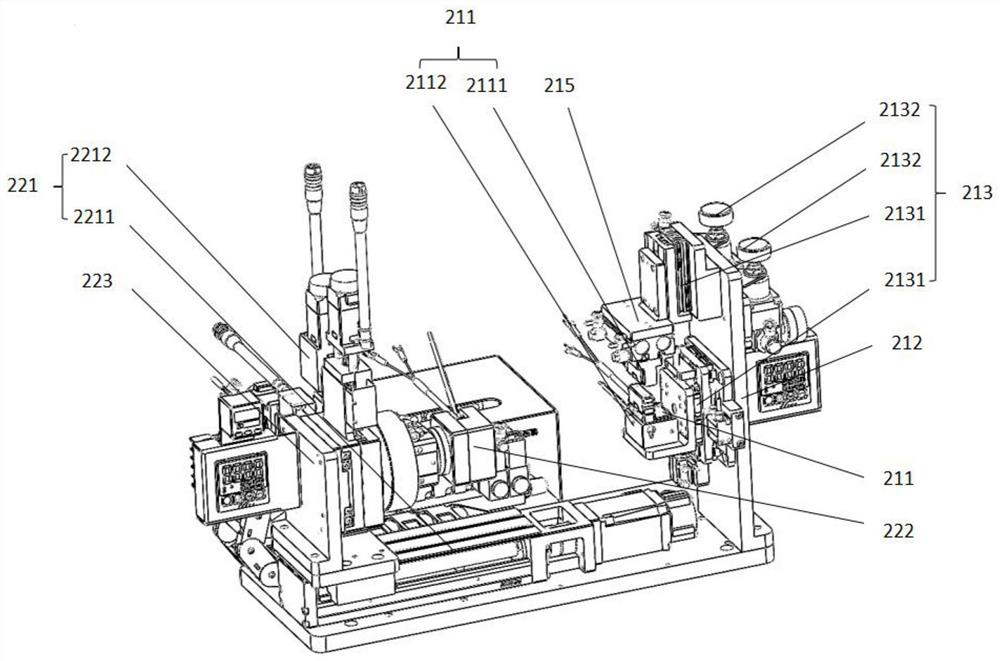

[0070] See attached Figure 1 to Figure 12 , this embodiment provides an assembly device for assembling the cables on the earphone casing, including a controller, a mounting plate 3, a rotating device 1, an image acquisition device 4 and at least three assembly devices 2;

[0071] The controller is electrically connected to the image acquisition device 4 and the assembly device 2 respectively;

[0072] The rotating device 1 includes a rotating disk 11 and a driving mechanism 12, at least three assembly devices 2 are evenly arranged on the rotating disk 11 along the circumferential direction, and the driving mechanism 12 can drive the rotating disk 11, and then Drive the assembly device 2 to rotate around the axis of the rotating disk 11;

[0073] The mounting plate 3 is provided with a loading and unloading station, an alignment installation station and at least one assembly and pressure holding station, and the loading and unloading station, the alignment installation statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com