Molten pool retainer of continuous casting billet flame cleaning machine

A technology of flame cleaning and retainer, which is applied in the field of metallurgy, can solve the problems of harsh working environment, dense staff, and large metal loss of billet cutting corners, etc., and achieve the effect of improving oxygen utilization rate, increasing oxygen concentration, and stabilizing cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

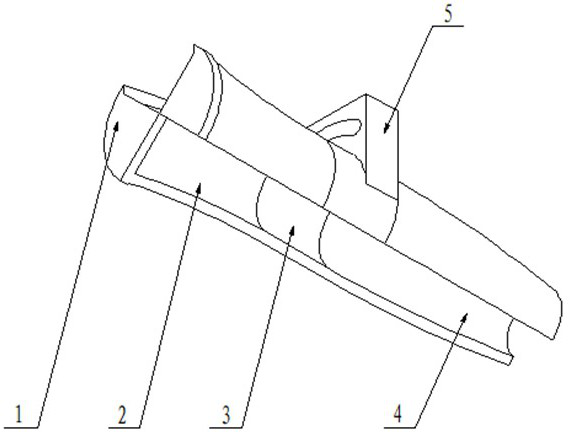

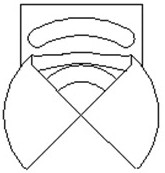

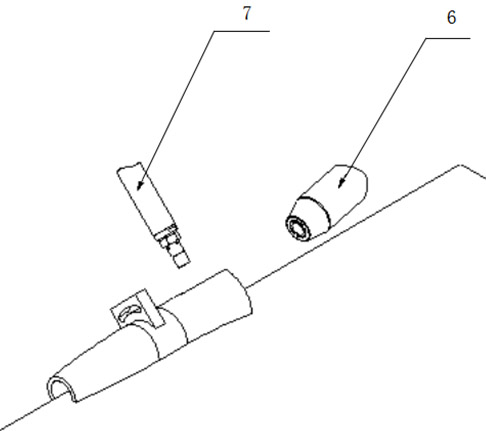

[0016] Such as figure 1 and figure 2 As shown, the structure schematic diagram of the invention is given. The device is composed of retainer front retaining wall 1, retainer front 2, retainer middle 3, retainer rear 4 and installation rib 5, wherein: retainer front retainer Wall 1, holder front 2, holder middle 3, holder rear 4 are coaxially arranged; holder front 2, holder middle 3, holder rear 4 are in the direction opposite to the top opening of holder front 2 A 90° opening is opened on the top; the retaining wall 1 at the front of the retainer is two 1 / 4 round structures, connected to the front 2 of the retainer; the front 2 of the retainer is contracted, and the opening at the top of the front 2 of the retainer is equal The combination of waist trapezoid and semicircle, the opening angle is 25°-35°; the middle part 3 of the cage is cylindrical, and there is a mounting rib 5 on it; the rear part 4 of the cage is contracted, and the length is 210mm-240mm; Welding sealing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com