Double-side-squeezing water squeezing device, cleaning tool and self-squeezing foamed cotton mop

A water squeezing device and side extrusion technology, applied in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve problems such as tearing of the bonding surface of foamed cotton, product damage, and relatively large extrusion force, and achieve The extrusion distance is small, the water extrusion resistance is reduced, and the effect of protecting the adhesion is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

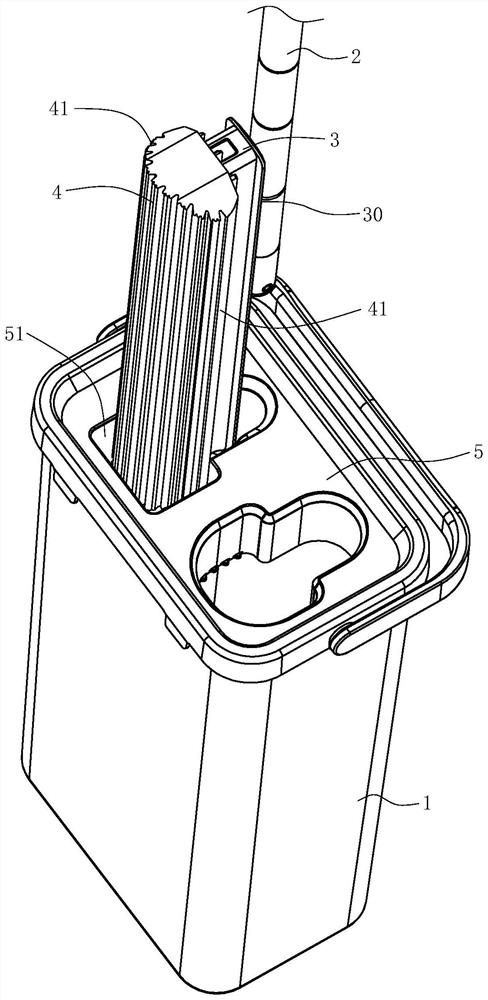

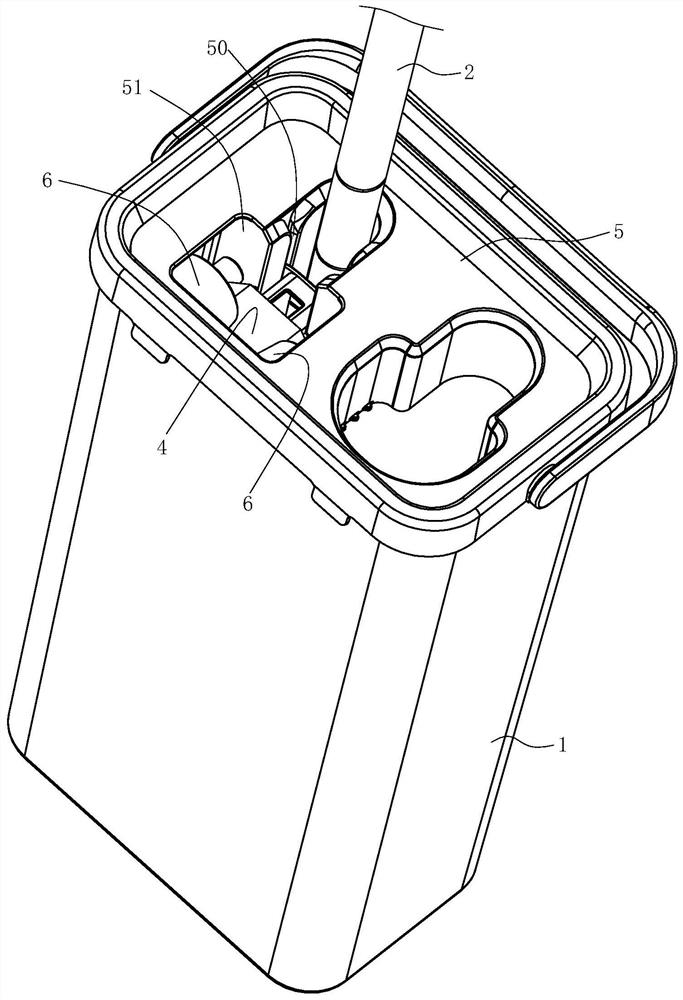

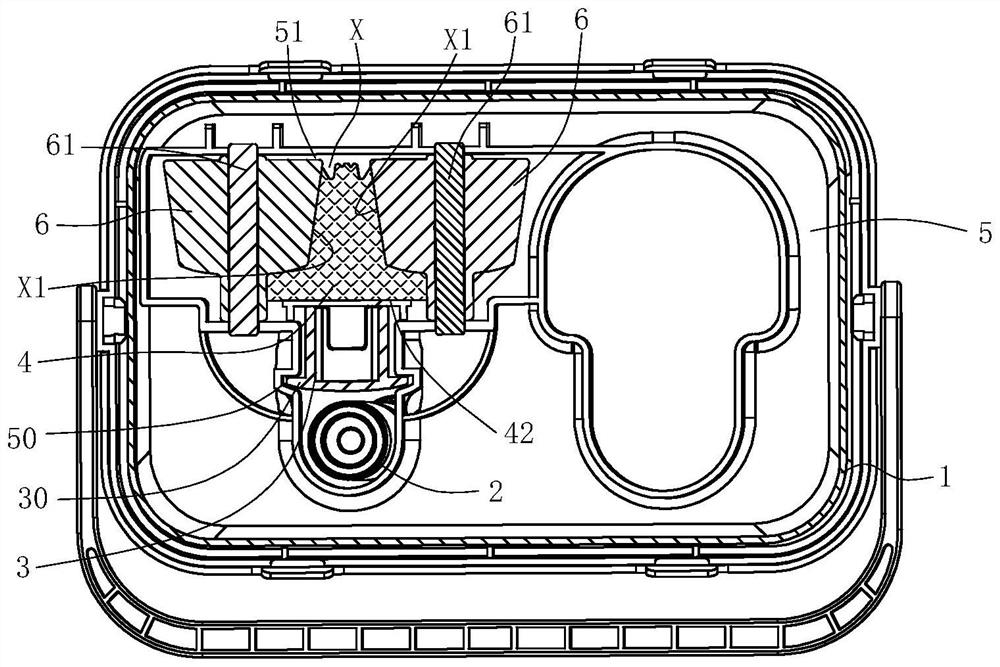

[0040] Such as Figure 1-7 , 12, 15, and 16 show the first preferred embodiment of the cleaning tool of the present invention.

[0041] A double-sided extruded foamed cotton mop cleaning tool, comprising a cleaning barrel 1 and a mop head 3 that is rotatably connected to the lower end of a mop rod 2, the bottom surface of the mop head 3 is directly or indirectly bonded with foamed cotton 4, such as Figure 12 As shown, the mop head 3 with the foamed cotton 4 directly bonded to the bottom surface refers to the foamed cotton 4 directly bonded to the base plate of the mop head 3, and the mop head 3 with the foamed cotton 4 indirectly bonded to the bottom surface refers to The foamed cotton 4 is bonded to the mounting plate first, and then the mounting plate is detachably connected to the bottom plate of the mop head 3 . The mop rod 1 can only s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com