Control method and control system for dynamic-humidity-control baking of tobacco leaves

A control method and technology of tobacco leaves, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of tobacco leaf yellowing and water loss, incoordination, etc., achieve improvement of leaf softness and structural porosity, and solve tobacco leaf yellowing and water loss Incongruity, the effect of reducing the loss of tobacco leaves during curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0039] Method example:

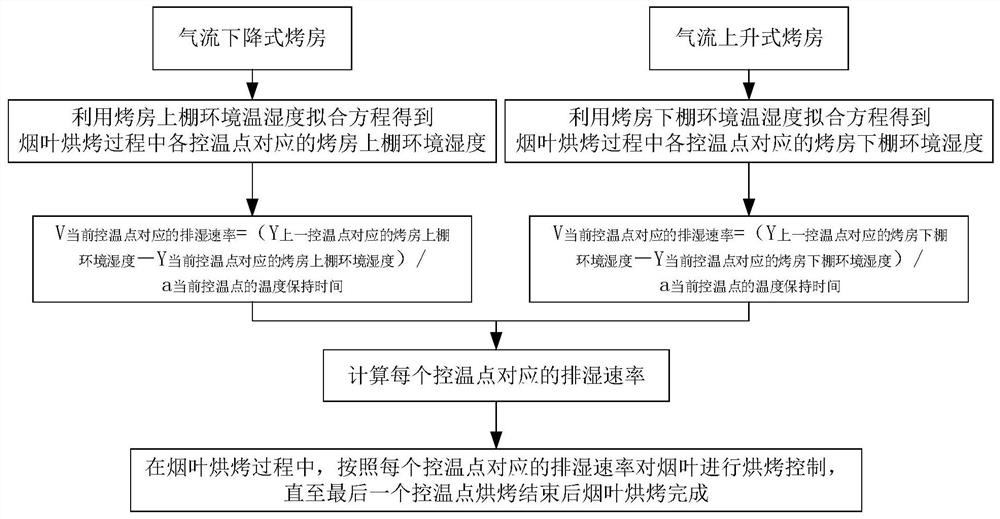

[0040] Such as figure 1 As shown, the tobacco leaf dynamic humidity control curing method of the present embodiment includes the following steps:

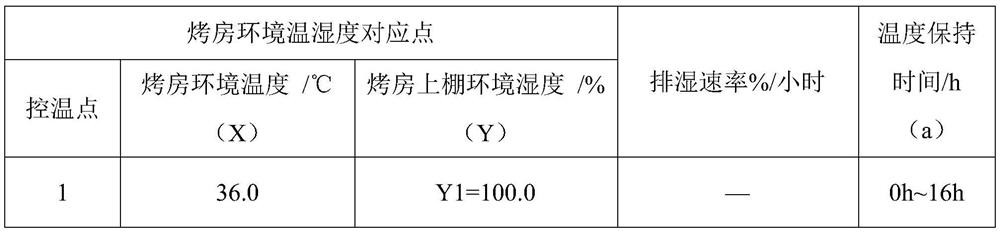

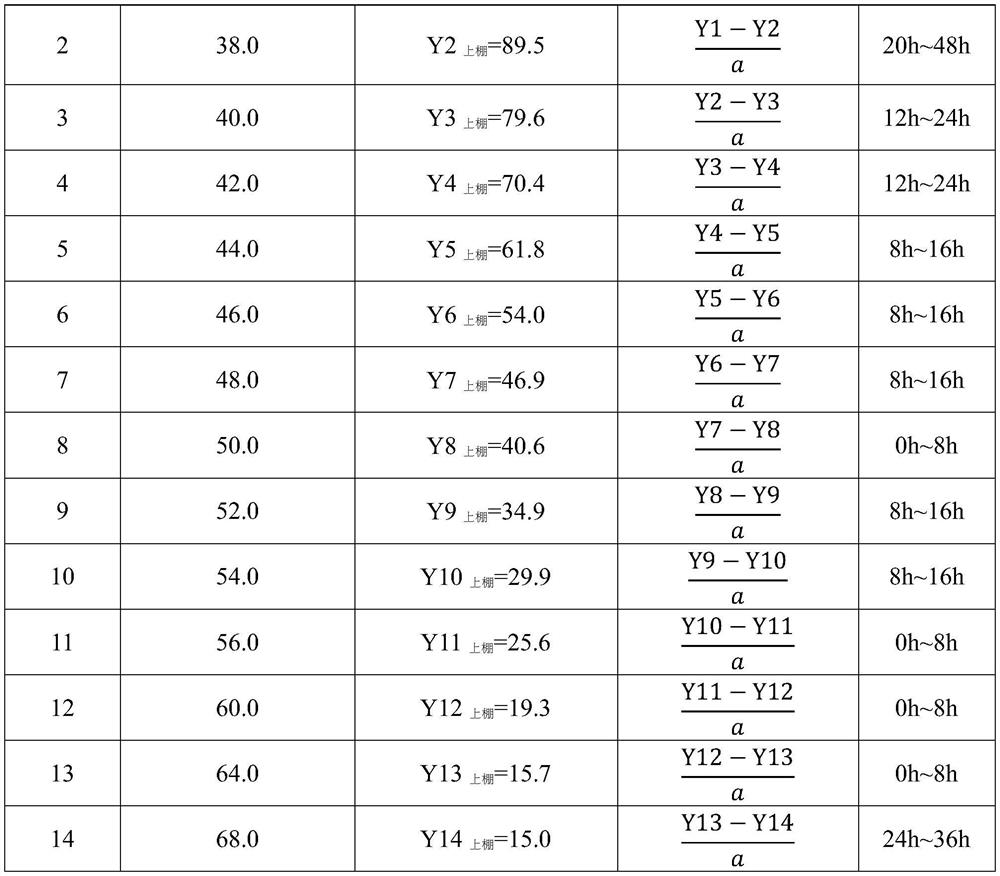

[0041] For the air-flow descending barn, by substituting the ambient temperature of the barn corresponding to each temperature control point in the tobacco leaf curing process into the previously determined temperature and humidity fitting equation of the upper barn of the barn, the environmental humidity of the upper barn of the barn corresponding to each temperature control point is obtained ; For the air-flow ascending barn, by substituting the ambient temperature of the barn corresponding to each temperature control point in the tobacco leaf curing process into the previous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com