Method for detecting a roughness in an abradable layer in a fan casing

A roughness and wear layer technology, applied in coatings, safety devices, machines/engines, etc., can solve problems such as wear layer degradation, avoid unreasonable returns, save time and money, and speed up inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

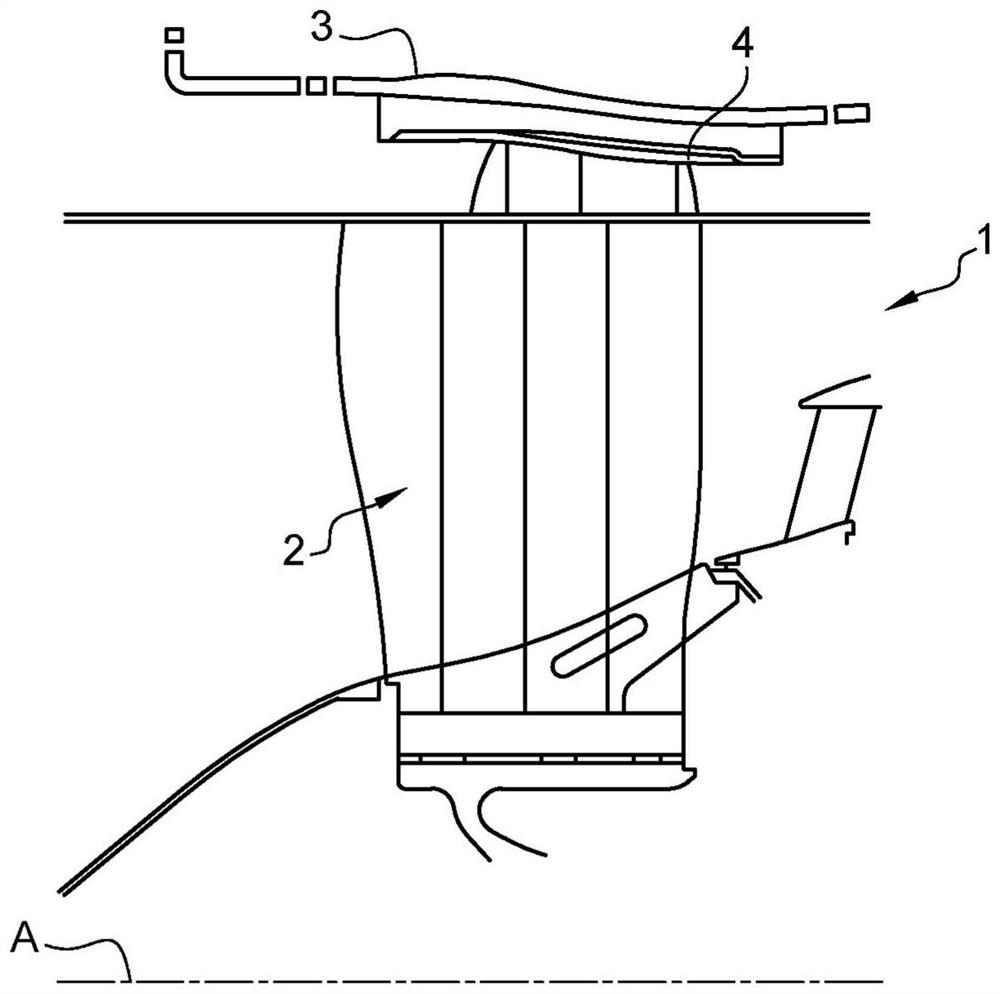

[0055] figure 1 is a partial schematic diagram of a fan of an aircraft turbine.

[0056] In a conventional manner, a turbomachine comprises, from upstream to downstream, i.e. in the direction of flow of the gas flow, a fan, one or more compressors, a combustor, one or more turbines and nozzles for injecting the combustion gases leaving the one or more turbines .

[0057] The fan 1 comprises a blade wheel 2 surrounded by a fan casing 3 which is also called a holding casing since the function of this fan casing is to hold the blades if they break or if debris enters the fan.

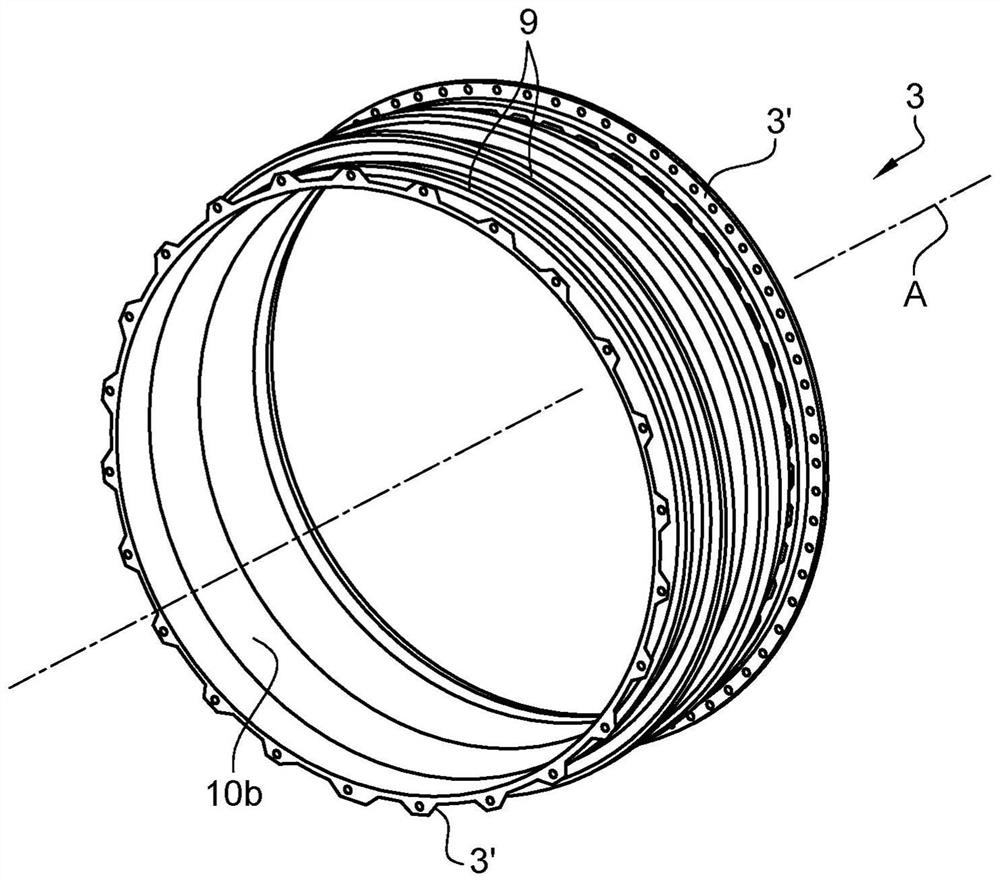

[0058] Such as figure 2 As shown, the fan housing 3 has a substantially cylindrical shape with an axis A of rotation.

[0059] The fan casing comprises at each of its axial ends an annular fixing flange 3'. These flanges 3' are used to fix the casing 3 to the annular wall of the nacelle of the turbine.

[0060] as it should figure 2 As shown, a layer 10b of abradable material is present inside the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com