State feedback monitoring system in activated carbon injection system

A technology of injection system and feedback monitoring, applied in sequence/logic controller program control, general control system, control/regulation system, etc., can solve problems such as reducing work efficiency, increasing wiring difficulty and error rate, and obsolescence, etc. Achieve the effect of meeting the needs of logic control, realizing adjustment and optimization, and eliminating the waste of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

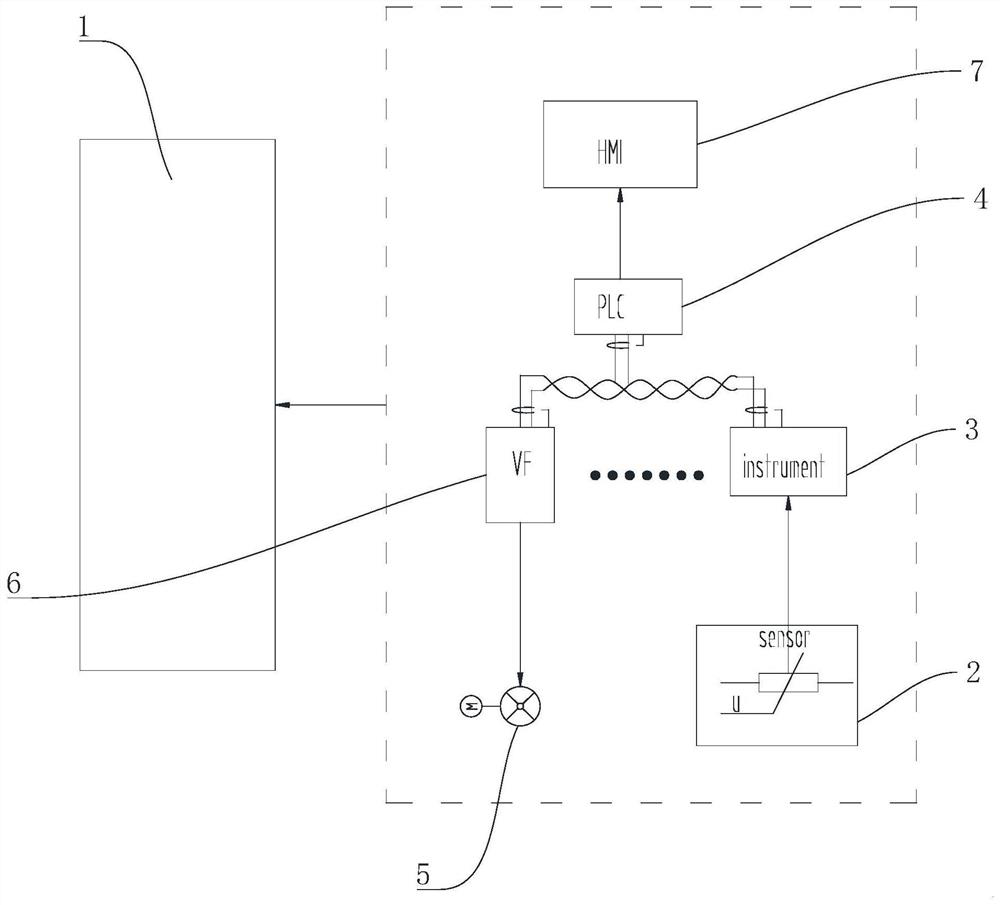

[0023] This embodiment provides a condition feedback monitoring system in an activated carbon injection system, the structure of which is as follows Figure 1 to Figure 2 As shown, including the control cabinet 1, it is characterized in that: also includes

[0024] A number of weighing sensors 2 are respectively used for real-time monitoring of the weight of materials in a single activated carbon injection system;

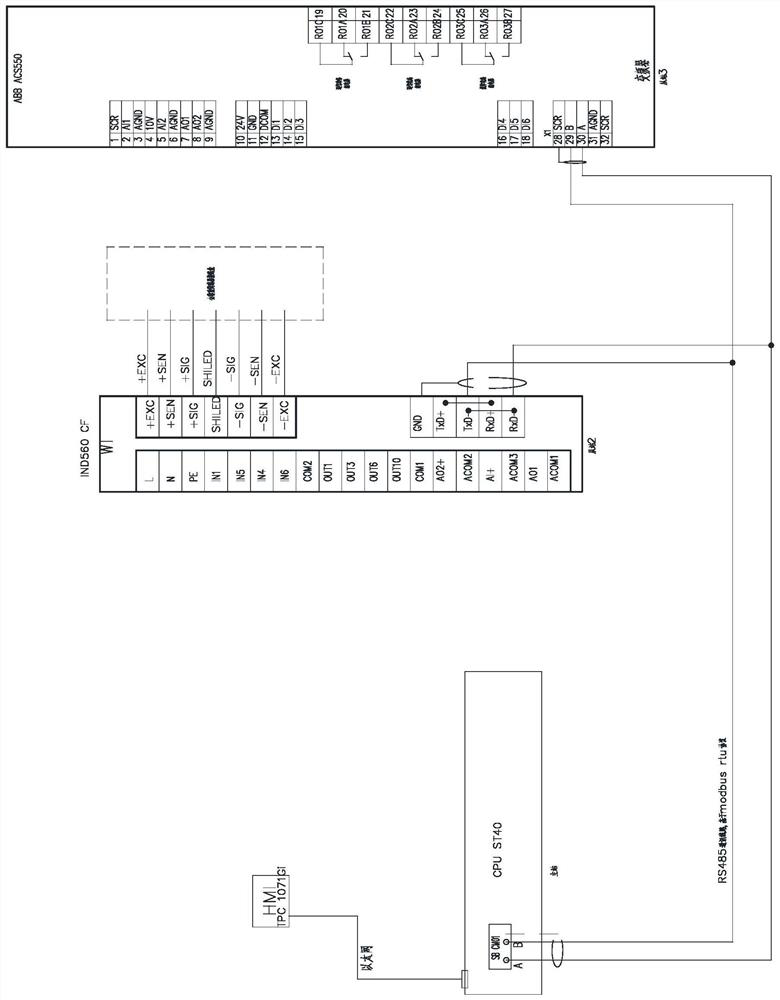

[0025] The control instrument 3 is electrically connected to each corresponding load cell 2, and is used to receive the data monitored by the load cell 2 and output the data signal to the outside, and the model of the control instrument 3 is set to IND560 CF;

[0026] The PLC system 4 is connected to the control instrument 3 through RS485, and the two communicate based on the modbus rtu communication protocol, receive the data signal transmitted by the control instrument 3, and output control commands to the outside through the processing of the data signal, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com