Power battery test system and method

A power battery and test system technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of short circuit of cells or modules, insufficient cooling liquid testing process, etc., and achieve comprehensive safety evaluation and simple system structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

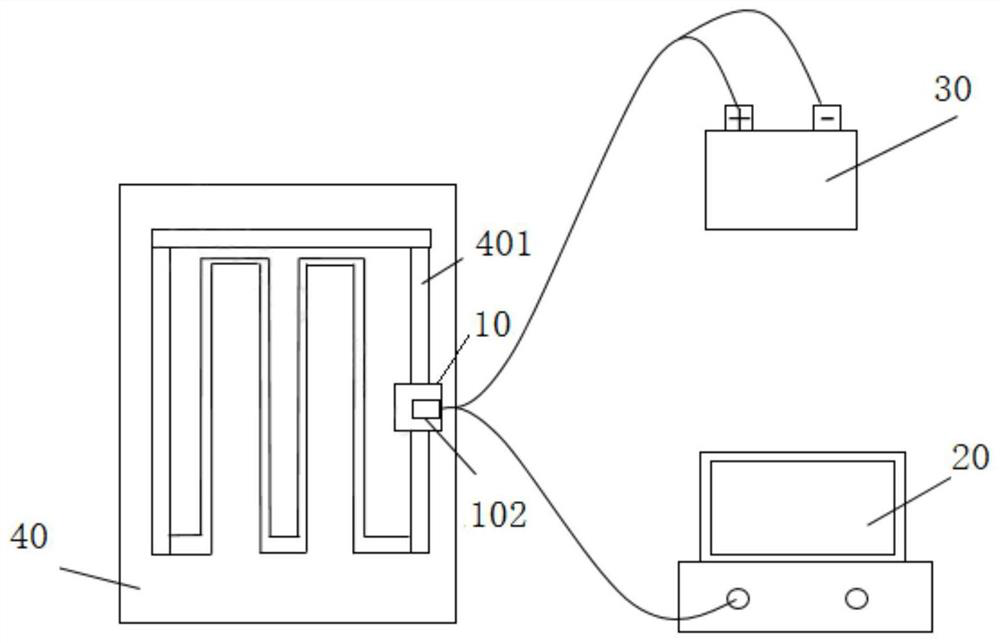

[0026] Embodiments of the present application by providing a battery test system and method, the system can verify the specific leak points condition, the battery power system simulation in the course of cooling liquid into the cooling circuit of the internal battery power more scene conditions, in order to achieve battery power system coolant leak scenario, the performance parameters of the battery pack more comprehensive safety assessment.

[0027] To better understand the above technical solutions, in conjunction with the following drawings and specific embodiments of the above technical solutions described in detail.

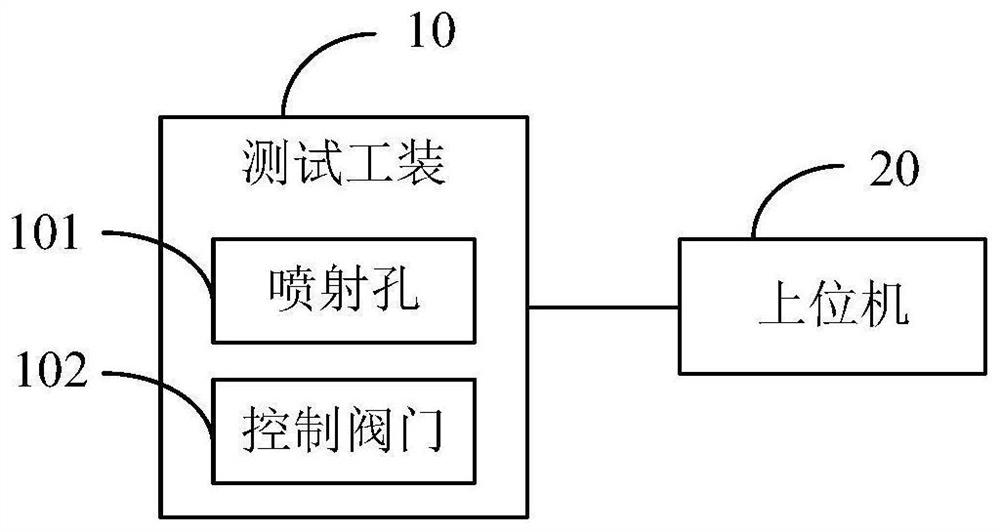

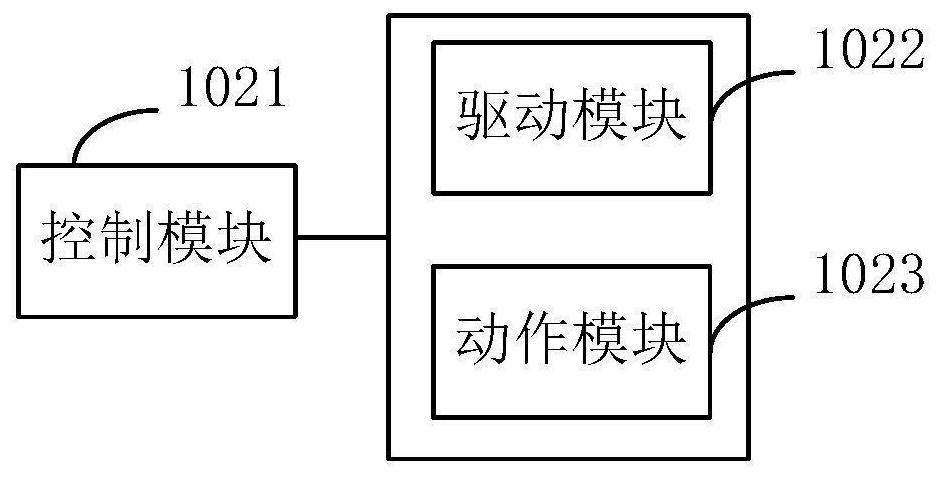

[0028] A first aspect, the present invention embodiment of a power provided by a battery testing system, specifically, such as figure 1 Shown, the system comprising: a test fixture 10. The test fixture 10 is attached to the cooling pipeline system battery test member corresponding to a target, comprising a test fixture 101 and a plurality of injection holes for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com