Welding tracking device and tracking method thereof

A tracking device and welding torch technology, which is applied in welding equipment, electrode characteristics, arc welding equipment, etc., can solve the problems of poor real-time tracking of welding seams, etc., and achieve the effect of high system operating frequency, high natural frequency and good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

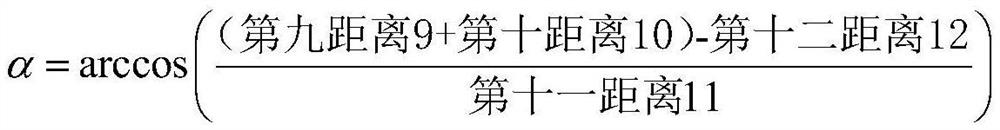

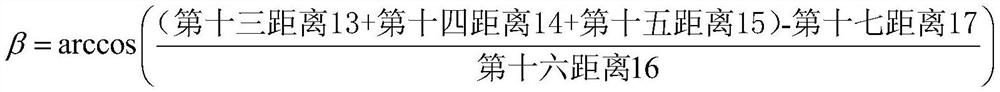

[0051] Such as Figure 1~5 As shown, the present invention includes a welding robot 1, a base plate 2, a vertical plate 3, a welding seam 4, a welding wire 5, a welding torch 6, a capacitor patch 7, an eighth distance 8, a ninth distance 9, a tenth distance 10, and an eleventh distance Distance 11, twelfth distance 12, thirteenth distance 13, fourteenth distance 14, fifteenth distance 15, sixteenth distance 16, seventeenth distance 17, working angle α, travel angle β.

[0052]The capacitor patch 7 on the welding torch 6 is laid out as eight equal parts of the circular array of the welding torch, and the length direction of the welding torch is a linear array of nine arrays. One purpose of the plurality of arrays is that the shape of the workpiece has uncertainty due to the uncertainty of the welding posture and position of the welding torch 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com