Biodegradation and purification system for VOCs produced during spraying of water-based paint

A biodegradation and purification system technology, which is applied in the field of water-based paint spraying VOC biodegradation purification system, can solve problems such as air pollution, poor adsorption effect, VOC air pollution, etc., achieve equipment manufacturing cost reduction, no fire safety hazards, and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

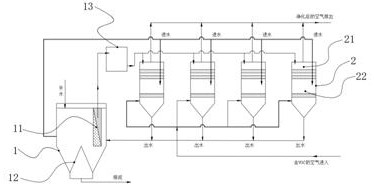

[0028] see figure 1 , in the embodiment of the present invention, the water-based paint spraying VOC biodegradation purification system includes an aerobic biochemical pool 1, several water spray biodegradation adsorption towers 2 and is located between the aerobic biochemical pool 1 and the water spray biodegradation adsorption tower 2 Between the clean water tank 13, the interior of the water spray biodegradation adsorption tower 2 is provided with an upper spray area 21 and a lower spray area 22 sequentially from top to bottom, and the inner bottom of the aerobic biochemical pool 1 is arranged as a cone 12, An MBR membrane group 11 is provided on the upper end side of the inside of the aerobic biochemical tank 1 .

[0029] Preferably, both the upper spraying area 21 and the lower spraying area 22 are provided with 2-3 layers of biological filtration membranes.

[0030] Preferably, the upper end of the aerobic biochemical pool 1 is provided with a water supply device, and o...

Embodiment 2

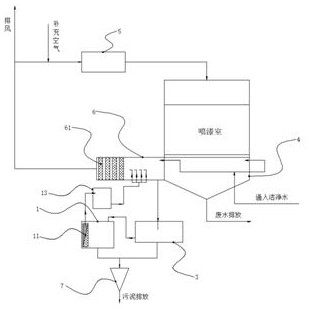

[0038] see figure 2 , in the embodiment of the present invention, the water-based paint spraying VOC biodegradation purification system includes paint aerobic biochemical tank 1, anaerobic treatment tank 3, fog treatment system 4, air supply air conditioner 5, spray chamber 6, sludge discharge tank 7 , one side of the inside of the spray chamber 6 is provided with a water retaining plate 61, the bottom of the aerobic biochemical pool 1 and the anaerobic treatment pool 3 are equipped with a sludge discharge tank 7, and the upper end side of the aerobic biochemical pool 1 is An MBR membrane group 11 is provided, and a clean water tank 13 is provided at the upper end of the MBR membrane group 11 .

[0039] Preferably, the implementation method includes the following steps:

[0040]S21. The paint mist generated during the spraying process of the spray booth is sent to the paint mist treatment system 4 through the air supply air conditioner 5, and the purified clean water is intr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com