Metal oxide modified battery diaphragm with self-assembled three-dimensional structure as well as preparation method and application of metal oxide modified battery diaphragm

A three-dimensional structure, battery separator technology, applied in structural parts, battery pack parts, circuits, etc., can solve problems such as low exposure rate, and achieve the effect of promoting transmission, improving cycle stability, and improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

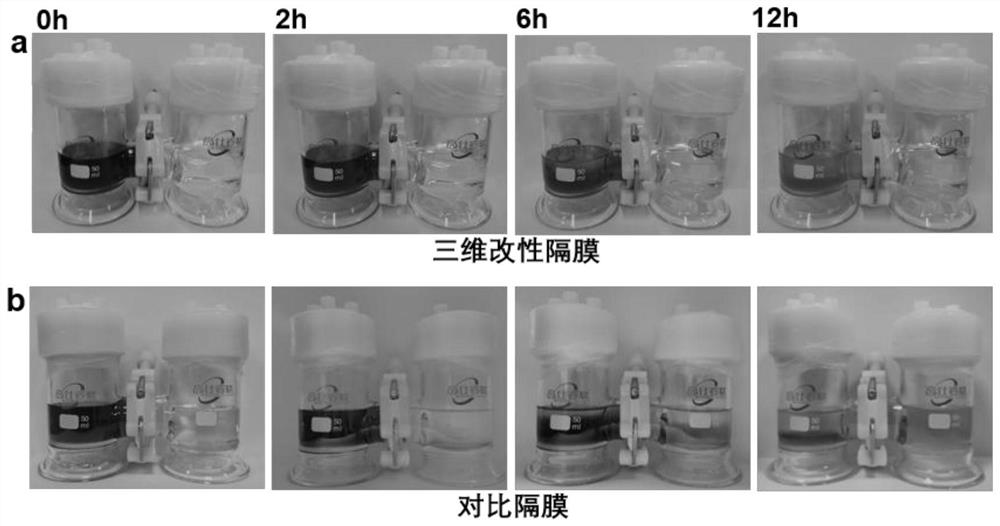

[0048] In this embodiment, a self-assembled three-dimensional structure of a metal oxide-modified battery separator (hereinafter referred to as a modified separator) and a preparation method thereof are described in detail, including the following steps:

[0049] (1) Preparation of metal-organic framework precursors: Cobalt nitrate hexahydrate and 2-methylimidazole were dissolved in 30 mL and 60 mL of methanol, respectively (the molar ratio of cobalt nitrate hexahydrate and 2-methylimidazole was 1:5) , mixed the above two solutions and ultrasonically reacted at 25 ° C for 1 h, after centrifugation, washing and drying, the cobalt-based metal organic framework precursor (hereinafter referred to as ZIF-67) was obtained;

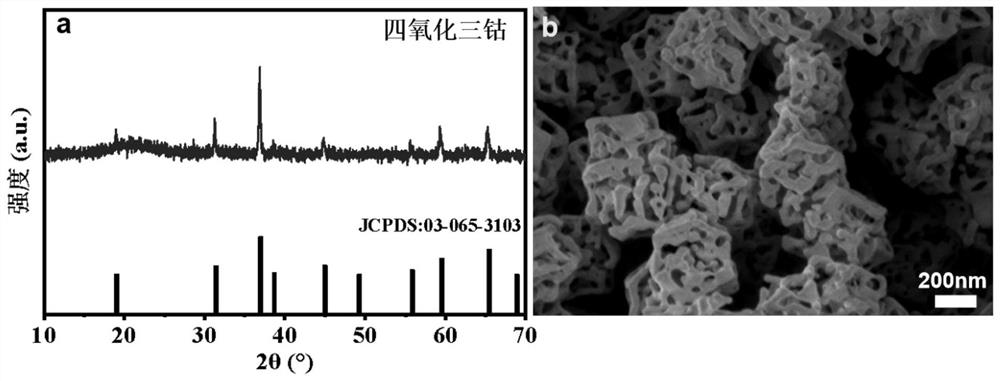

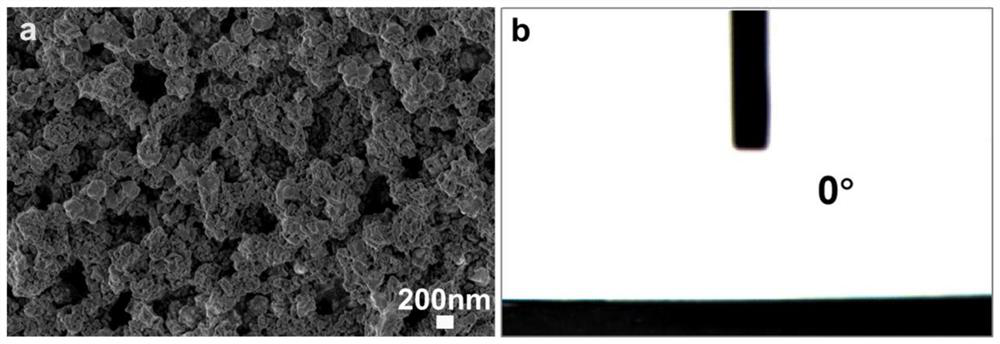

[0050] (2) Preparation of local three-dimensional cross-linked metal oxide: ZIF-67 was annealed at 470 °C for 1 h at a heating rate of 5 °C / min in an air atmosphere to synthesize local three-dimensional cross-linked cobalt tetroxide (hereinafter referred to as co...

Embodiment 2

[0061] In this embodiment, a self-assembled three-dimensional structure of a metal oxide-modified battery separator (hereinafter referred to as a modified separator) and a preparation method thereof are described in detail, including the following steps:

[0062] (1) Preparation of metal-organic framework precursors: zinc nitrate hexahydrate and 2-methylimidazole were dissolved in 30 mL and 60 mL of methanol, respectively (the molar ratio of zinc nitrate hexahydrate and 2-methylimidazole was 1:5) , mixed the above two solutions and ultrasonically reacted at 25 °C for 1 h, and after centrifugal washing and drying, the zinc-based metal organic framework precursor (hereinafter referred to as ZIF-8) was obtained;

[0063] (2) Preparation of local three-dimensional cross-linked metal oxides: ZIF-8 was annealed at 470 °C for 1 h at a heating rate of 5 °C / min in an air atmosphere to synthesize local three-dimensional cross-linked zinc oxide (hereinafter referred to as ZnO). Zinc oxid...

Embodiment 3

[0066] In this embodiment, a self-assembled three-dimensional structure of a metal oxide-modified battery separator (hereinafter referred to as a modified separator) and a preparation method thereof are described in detail, including the following steps:

[0067] (1) Preparation of metal-organic framework precursor: Dissolve ferric chloride hexahydrate and terephthalic acid in 30 mL of N,N-dimethylformamide (wherein the molar ratio of ferric chloride hexahydrate and terephthalic acid is 2:1), stirred for 30min, then put the above solution into the reaction kettle and reacted at 110°C for 12h, after centrifugal washing and drying, the iron-based metal organic framework precursor (hereinafter referred to as Fe-MOF) was obtained;

[0068] (2) Preparation of local three-dimensional cross-linked metal oxides: Fe-MOF was annealed at 400 °C for 2 h at a heating rate of 2 °C / min in an air atmosphere to synthesize local three-dimensional cross-linked ferric oxide ( hereinafter referred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com