Hydropower station gate gliding lifting and alarming method

A technology for hydropower stations and gates, applied in water conservancy projects, program control, sea area engineering, etc., can solve the problems of main equipment loss, unfavorable manual intervention, smashing of passing vehicles, etc., and achieve the effect of avoiding misoperation and abnormal opening of gates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

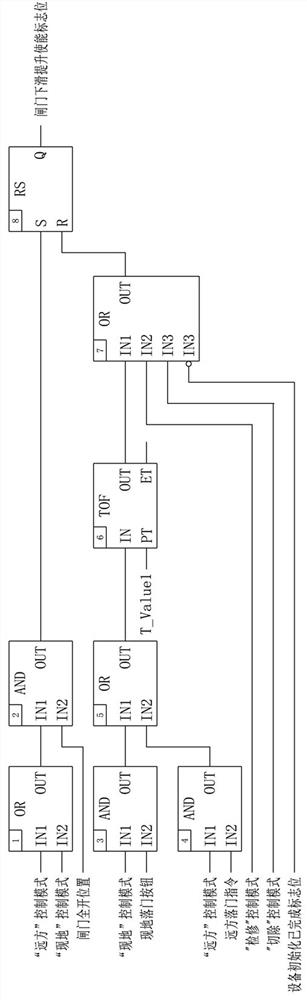

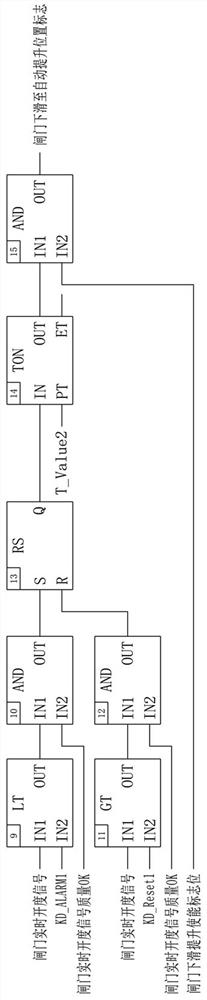

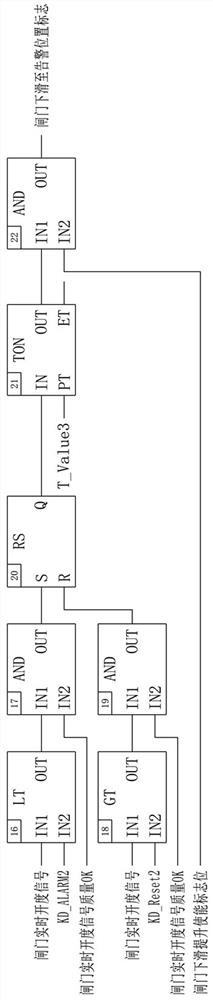

[0042] Such as Figure 1~Figure 4 Among them, a method for lifting and alarming the gate of a hydropower station, which includes three gate opening alarm action value variables KD_ALARM1, KD_ALARM2, and KD_ALARM3, and three gate opening alarm reset value variables KD_Reset1, KD_Reset2, and KD_Reset3, and T_Value1 and T_Value2 , T_Value3, T_Value4 four timer time variables;

[0043] Step 1, put in the "gate slide lift enable flag";

[0044] Step 1-1, through the output of the first output module 1 or the second output module 5, the first computing module 2 and the second output module 5, the first bistable module 8 is triggered, and the bistable function with priority is reset to realize the on-site switching of the gate. Or after the remote side is normally lifted to the fully open position, the gate control system will automatically put into the "gate slide lift enable flag";

[0045] Step 1-2, through the second operation module 3 and the second output module 5, the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com