Adjustable circular tube energy absorption/energy storage mechanism based on paper-cut structures

A technology of energy storage mechanism and circular tube, applied in mechanical equipment, springs/shock absorbers, springs made of plastic materials, etc., can solve the problems that impact-resistant structures cannot be recycled and energy cannot be recovered, and achieve stable and repeatable performance. Usability, light weight, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

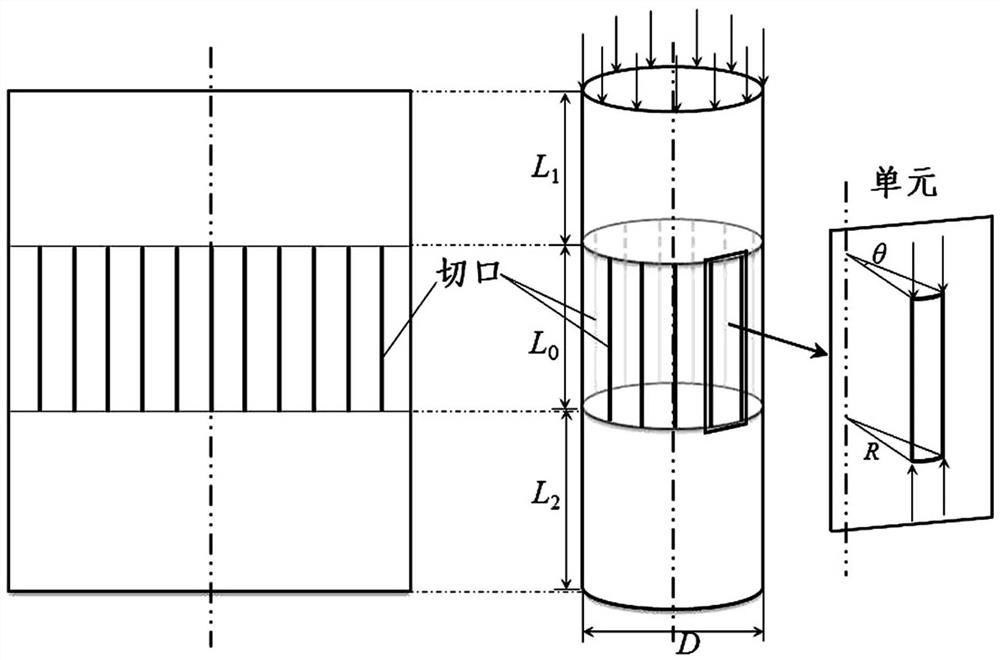

Method used

Image

Examples

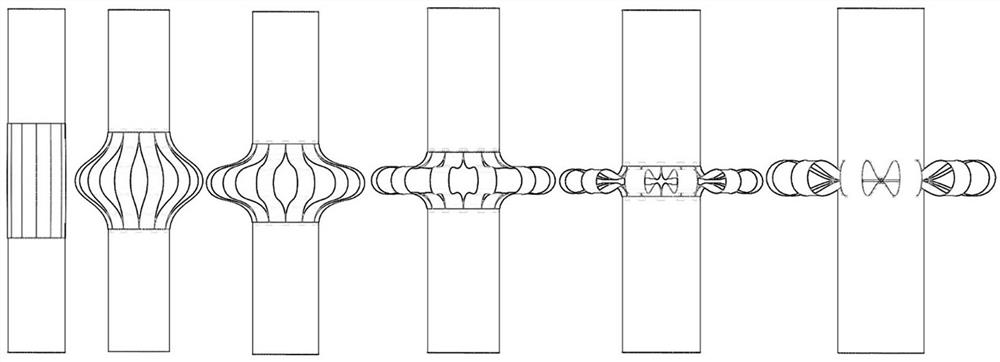

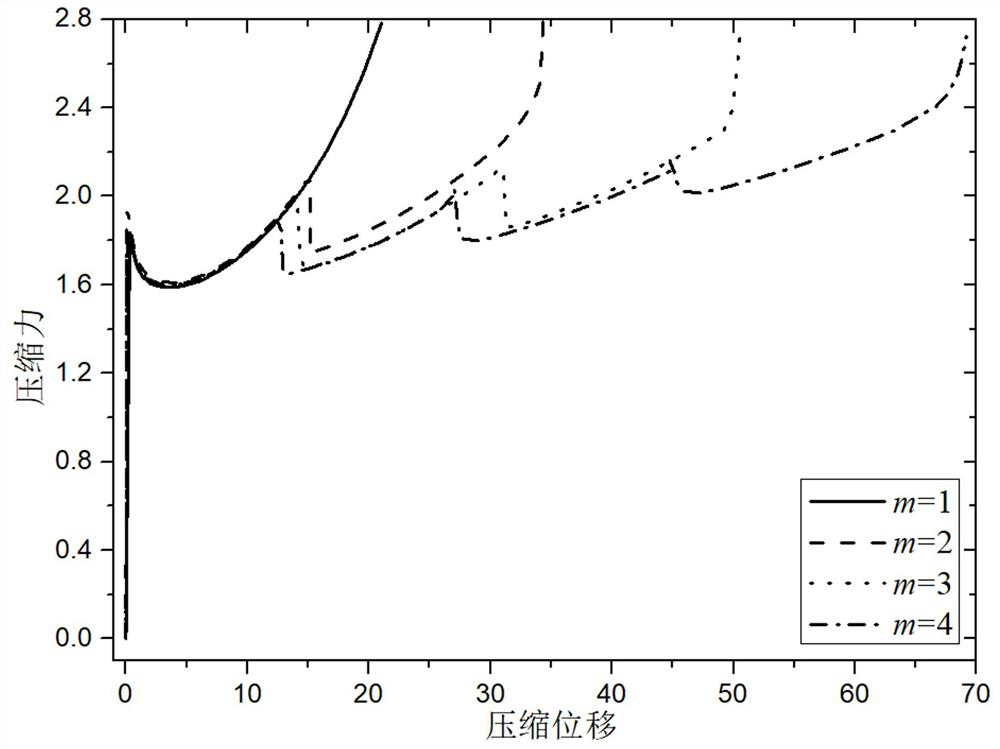

Embodiment 1

[0022] Take the number m of different paper-cut sections, which are 1, 2, 3, and 4 respectively. The height of the paper-cut section and the uncut section are both 20 mm, and the number of support arms of the paper-cut section is 12. The static displacement compression load of 20×m mm is applied to the number m of different paper-cut sections, and the force-displacement response curves of different structures are obtained, as shown in the attached image 3 shown. attached Figure 4 The deformation simulation diagrams corresponding to different stages of the circular tube are given when the quantity m=4. For the number m of paper-cut segments, m times of instability will occur during the whole deformation process, that is, there will be m critical buckling stresses. As the number m increases, the force-displacement response curve becomes longer and smoother, which means that its deformation stroke is longer, which will provide a reference for a structure with good energy abs...

Embodiment 2

[0024] as attached Figure 5 As shown, take the 11×11 circular tubes in Example 1 and make a square array with equal spacing between the circular tubes. The circular tubes are placed in the perforated plate as shown in the figure (the number of plates can be increased appropriately) Fix the tube position. The total height of the circular tubes, the distance between each circular tube and the position of the paper-cut section can be arbitrarily selected according to the actual situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com