Multipurpose high-performance woolen fabric and preparation method

A multi-purpose, high-performance technology, applied in the field of fabric production, can solve the problems of poor tear resistance and tensile performance, time-consuming and labor-intensive cleaning, and lower fabric quality, so as to enhance skin affinity, speed up cleaning and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0043] Example 1:

[0044] A multi-purpose high-performance fabric, formulation includes: silk fiber, polyester fiber, organic conductive fiber, polyester fiber and cotton fiber, weight parts of each component are: 100 parts of silk wool fiber, 20 parts Polyester fibers, 5 parts of organic conductive fibers, 15 parts of polyester fibers and 5 parts of moiner fibers, and polyester fibers are DTY, FDY, 50D24F, and 75D114F, organic conductive fibers are poly One or more mixtures of acetylene fibers, polyaniline fibers and polypyrrolers.

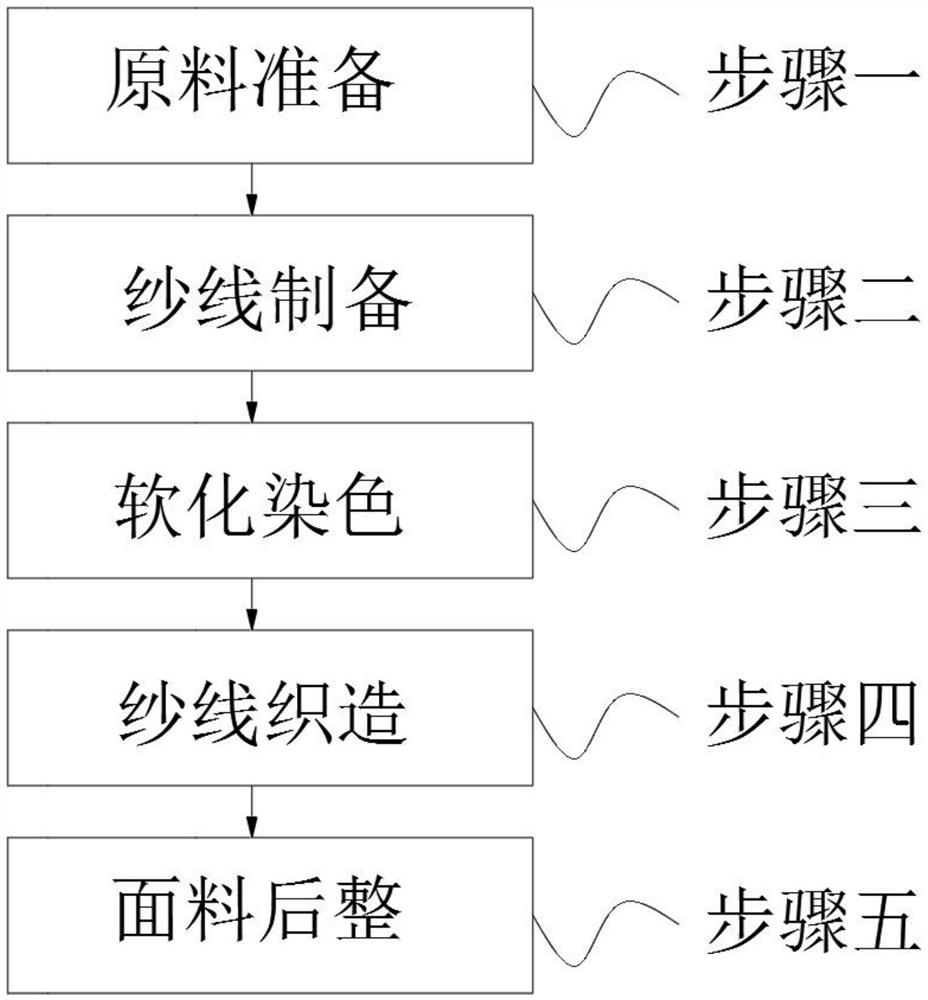

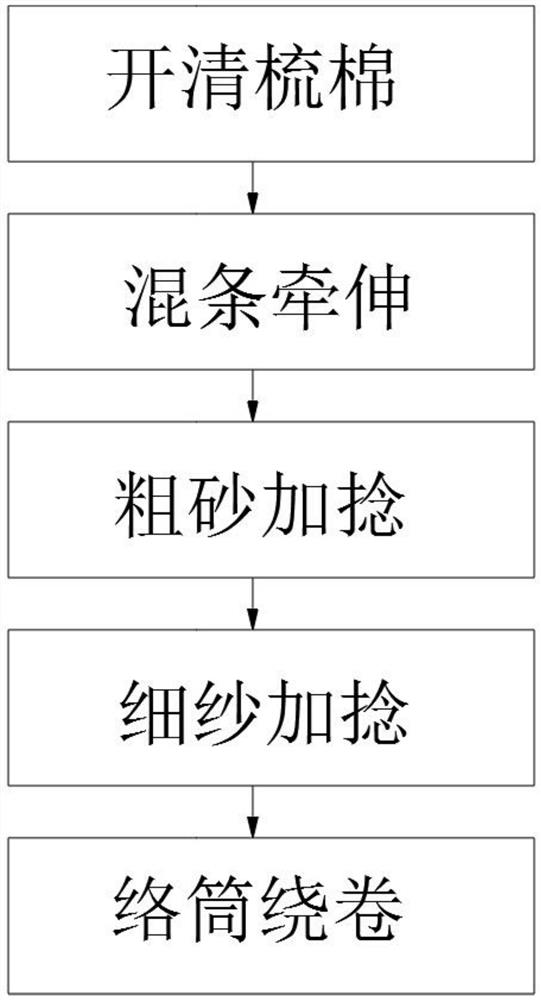

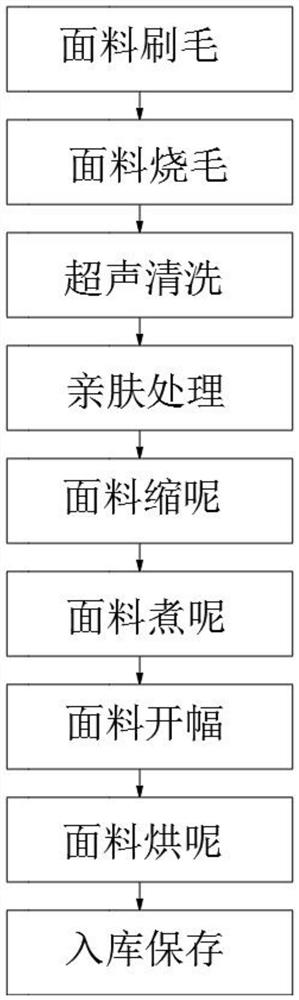

[0045] A method of preparing a multi-purpose high-performance fabric, including the following steps, step 1, raw material preparation; step two, yarn preparation; step three, softening staining; step four, yarn woven; step five, fabric back;

[0046] In the above steps, in the above-described steps, 100 parts of the meter fiber, 20 parts of polyester fiber, 5 parts of organic conductive fibers, 15 parts of polyester fibers and 5 parts of cotton were...

Example Embodiment

[0065] Example 2:

[0066] A multi-purpose high-performance fabric, formulation includes: silk fiber, polyester fiber, organic conductive fiber, polyester fiber and cotton fiber, weight parts of each component are: 120 wire wool fibers, 30 parts Polyester fibers, 10 parts of organic conductive fibers, 20 parts of polyester fibers and 10 parts of cotton fibers, and the polyester fibers are DTY, FDY, 50D24F, and 75D114F, organic conductive fibers are poly One or more mixtures of acetylene fibers, polyaniline fibers and polypyrrolers.

[0067] A method of preparing a multi-purpose high-performance fabric, including the following steps, step 1, raw material preparation; step two, yarn preparation; step three, softening staining; step four, yarn woven; step five, fabric back;

[0068] In the above steps, 120 copies of moisture wool fibers, 30 parts of organic conductive fibers, 20 parts of polyester fibers, 20 parts of polyester fibers, and 10 parts of coat were carried out in the abov...

Example Embodiment

[0087] Example 3:

[0088] A multi-purpose high-performance fabric, formulation including: silk wool fiber, polyester fiber, organic conductive fiber, polyester fiber, and cotton fiber, weight parts of each component are: 110 silk wool fibers, 25 parts Polyester fibers, 8 parts of organic conductive fibers, 18 parts of polyester fibers and 8 parts of cotton fibers, and polyester fibers are DTY, FDY, 50D24F, and 75D114F, organic conductive fibers are poly One or more mixtures of acetylene fibers, polyaniline fibers and polypyrrolers.

[0089] A method of preparing a multi-purpose high-performance fabric, including the following steps, step 1, raw material preparation; step two, yarn preparation; step three, softening staining; step four, yarn woven; step five, fabric back;

[0090] In the above steps, in accordance with the weight of the components, 110 parts of silk wool fibers, 25 parts of polyester fibers, 8 parts of organic conductive fibers, 18 parts of polyester fibers and 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com