Preparation method of waterproof adhesive

A waterproof adhesive and mixture technology, applied in the direction of adhesive additives, adhesive types, polymer adhesive additives, etc., can solve problems such as easy mildew, affecting adhesive bonding performance, breeding bacteria, etc., to achieve improved The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

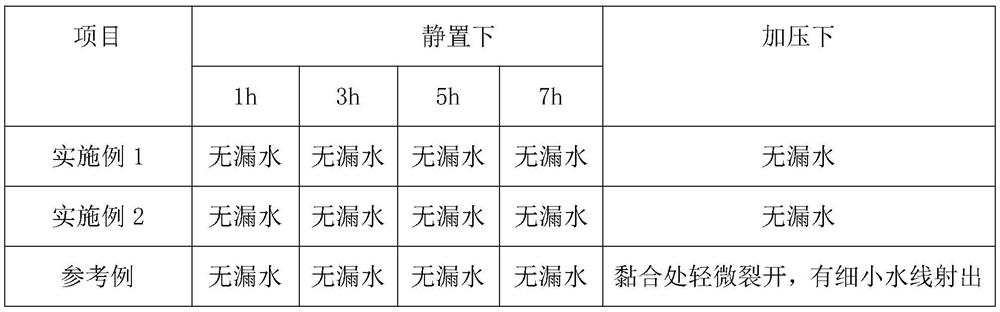

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a waterproof adhesive includes the following components in parts by weight: 70 parts of epoxy resin, 48 parts of epoxy resin curing agent, 9 parts of emulsifier, 5 parts of pH regulator, and 12 parts of anti-mold and antibacterial agent , Anti-aging agent 12 parts, antifreeze agent 11 parts, filler 11 parts, defoamer 9 parts, dispersant 10 parts.

[0019] Further, a preparation method of a waterproof adhesive, comprising the steps of:

[0020] S1: Put epoxy resin, anti-mold and antibacterial agent, anti-aging agent, antifreeze agent and plasticizer into the reaction kettle, heat up to 55 °C at a rate of 3 °C / min, add emulsifier and continue stirring for 30 min, and then Degassing under vacuum;

[0021] S2: adjusting the pH value of the vacuum-degassed epoxy resin to 7 with a pH value regulator to prepare an adhesive;

[0022] S3: Put the adhesive, dispersant, filler, epoxy resin curing agent, and defoamer into a mixer and mi...

Embodiment 2

[0029] A waterproof adhesive, comprising the following components by weight: 60 parts of epoxy resin, 40 parts of epoxy resin curing agent, 7 parts of emulsifier, 3 parts of pH regulator, 9 parts of anti-mold and antibacterial agent, 7 parts of anti-aging agent , 9 parts of antifreeze, 10 parts of plasticizer, 12 parts of defoamer, 12 parts of dispersant;

[0030] Further, a preparation method of a waterproof adhesive, comprising the steps of:

[0031] S1: Put epoxy resin, anti-mold and antibacterial agent, anti-aging agent, antifreeze agent and plasticizer into the reaction kettle, heat up to 60°C at a rate of 4°C / min, add emulsifier and continue stirring for 30min, and then Degassing under vacuum;

[0032] S2: adjusting the pH value of the vacuum-degassed epoxy resin to 7 with a pH value regulator to prepare an adhesive;

[0033] S3: Put the adhesive, dispersant, filler, epoxy resin curing agent, and defoamer into a mixer and mix to prepare a waterproof adhesive.

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com