Creasing machine and creasing and cementing machine

An indentation machine and indentation glue technology, which is applied in the directions of transportation and packaging, machining/deformation, object supply, etc., can solve the problems of defective products with reduced glue binding accuracy, relative position movement, and indentation position offset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

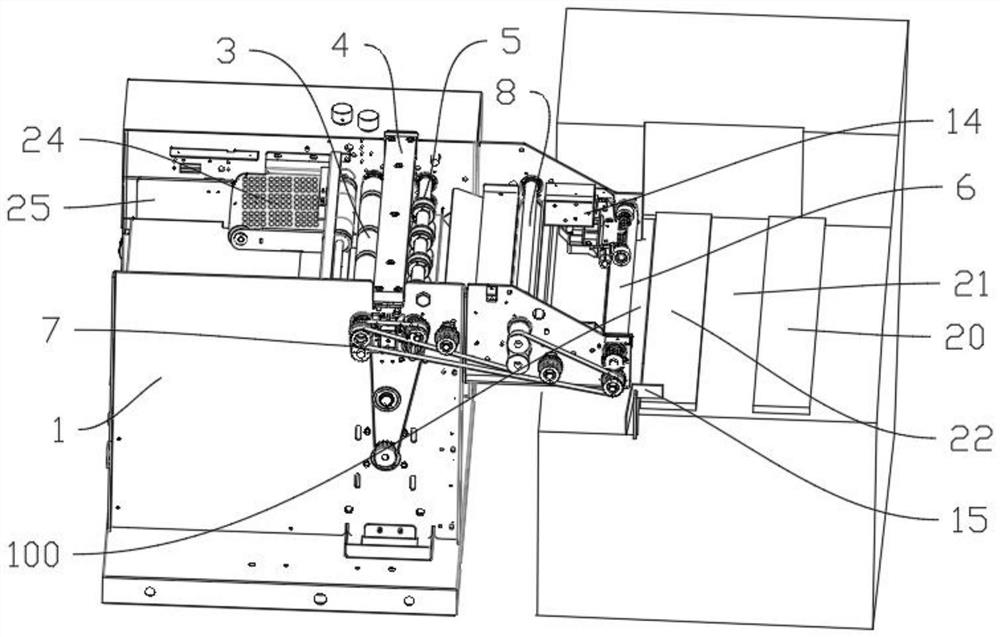

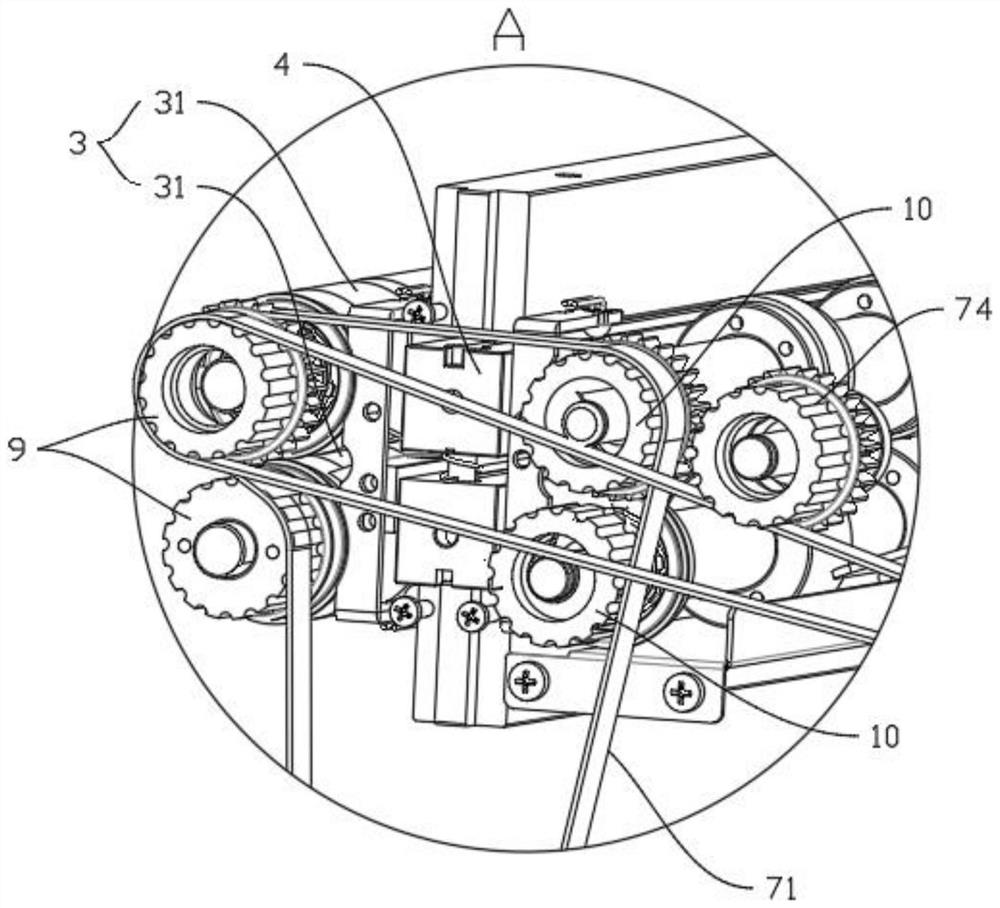

[0039] Such as Figures 1 to 11 As shown, a creasing machine is provided in this embodiment, which includes a creasing frame 1, and also includes a transmission mechanism 7 and a control module. The creasing frame 1 is sequentially provided with a paper backing plate 25, The suction paper assembly 24, the first rubber roller assembly 3, the creasing assembly 4, the second rubber roller assembly 5, the third rubber roller assembly 8 and the paper feeding roller 6, the paper feeding roller 6 is arranged on the paper output of the creasing frame 1 end 100, the creasing frame 1 is also provided with a motor 2, the first rubber roller assembly 3 is provided with a first transmission member, the second rubber roller assembly 5 is provided with a second transmission member, and the third rubber roller assembly 8 is provided with a A third transmission part is provided, and a fourth transmission part is provided on the paper feed roller 6. The motor 2 drives the transmission mechanism...

Embodiment 2

[0047] Such as Figure 12 , 13 As shown, in this embodiment, a creasing and perfecting machine is provided, including the creasing machine in Embodiment 1, and also includes a glue-binding frame 27, and a magnet block 29 is passed between the creasing frame 1 and the glue-binding frame 27 Connection; the indentation frame 1 is provided with a screw 30, the screw 30 is a positive and negative thread screw, that is, the thread at one end of the screw 30 is left-handed, and the thread at the other end is right-handed. The protrusion 31 of the distance between the magnet blocks 29, the shape of the protrusion 31 can preferably be a nut type; one end of the screw rod 30 is threadedly connected to the indentation frame 1 and can be inserted into the indentation frame 1, and the other end is threadedly connected with a U-shaped The casing 28 and the magnet block 29 are connected in the casing 28 by bolts, and the screw rod 30 is connected to the magnet block 29 by connecting the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com