Damping mechanism and mixer truck

A shock-absorbing mechanism and shock-absorbing technology, applied in springs/shock absorbers, cement mixing devices, mechanical equipment, etc., can solve the problem that the reducer cannot achieve any angle, so as to ensure stability and safety, and improve service life. , Improve the effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

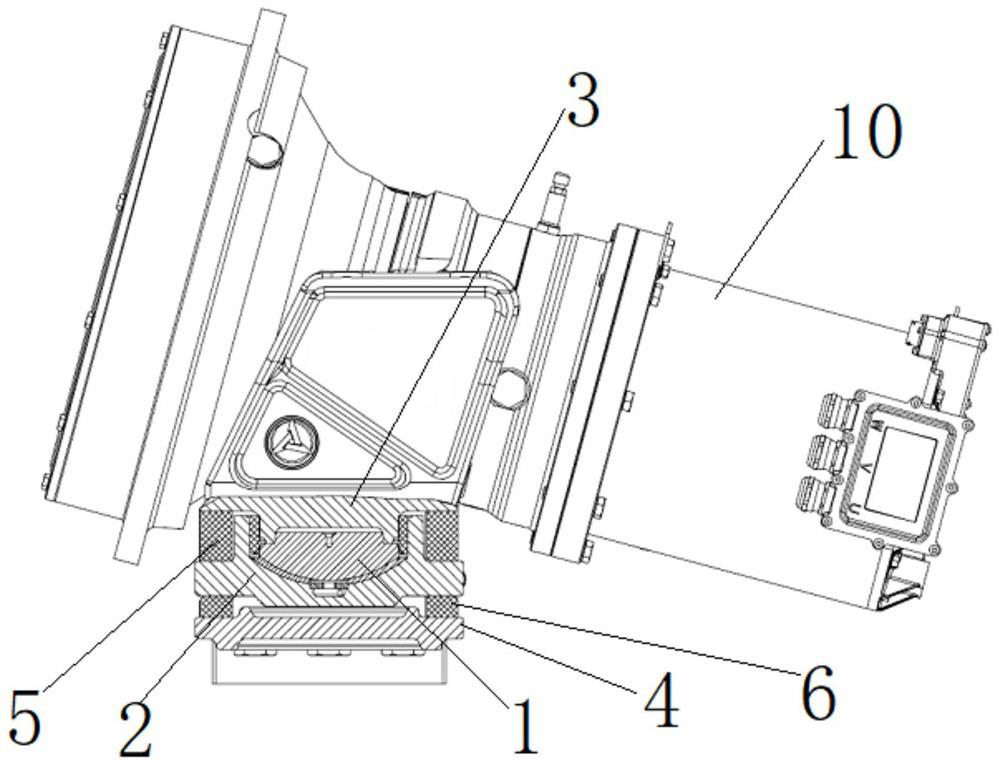

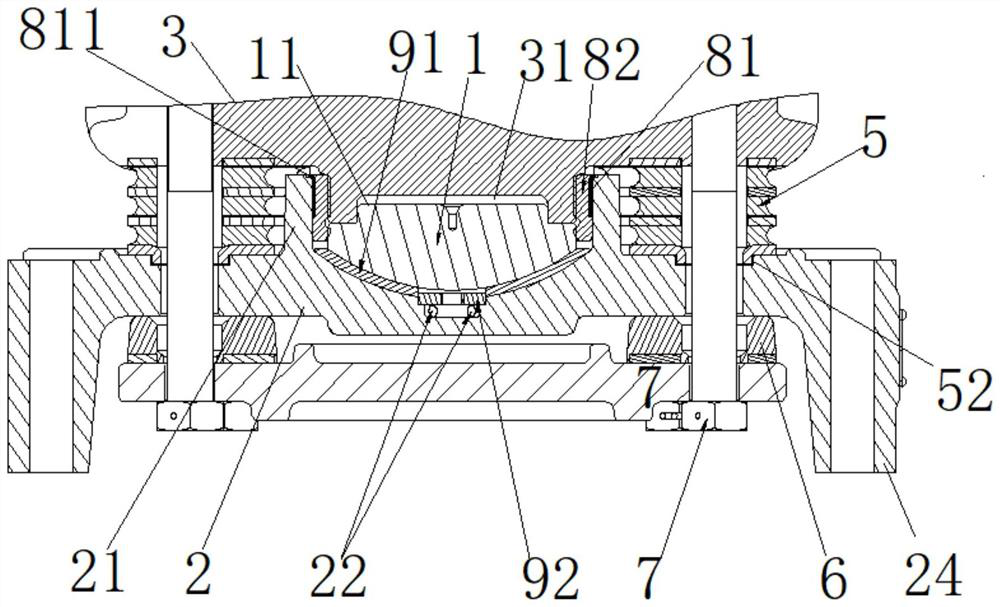

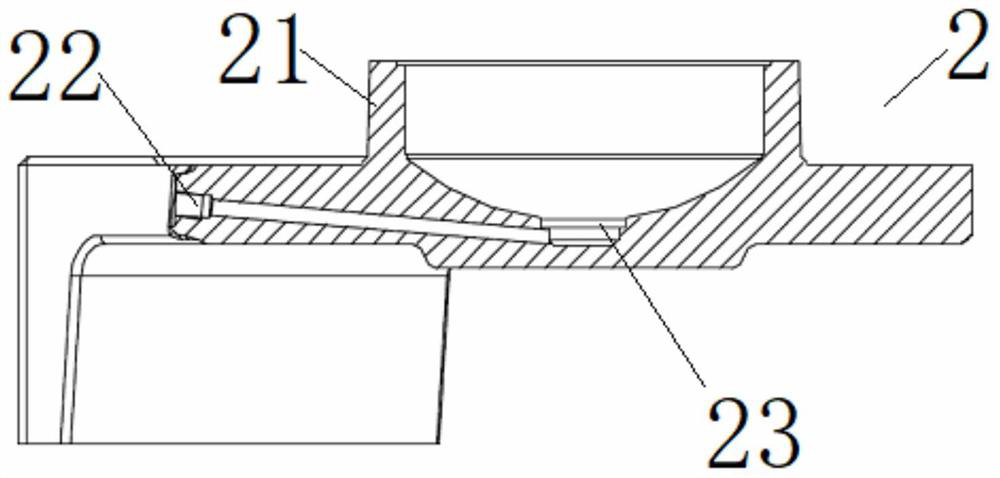

[0060] This embodiment provides a shock absorbing mechanism, such as figure 1 and figure 2 As shown, it includes a deflection part 1 , a support seat 2 , a fixed seat 3 , a bottom plate 4 , a first shock absorber 5 , a second shock absorber 6 and a fastener 7 . Wherein, the bottom surface of the swing part 1 is an arc surface; the support seat 2 has a mounting groove matching the shape of the bottom surface of the swing part 1, and the swing part 1 is rotatably arranged in the mounting groove; The outer circumference of the top of the installation groove is protrudingly provided with an annular sleeve part 21; the fixed seat 3 is arranged on the top of the support seat 2 and is fixedly connected with the swing part 1; the bottom plate 4 is arranged at the bottom of the support seat 2; The shock element 5 is arranged between the fixed seat 3 and the support seat 2; the second shock absorber 6 is arranged between the support seat 2 and the bottom plate 4; the fasteners 7 are t...

Embodiment 2

[0076] This embodiment provides a mixer truck, which includes the shock absorbing mechanism and the speed reducer 10 in Embodiment 1, the speed reducer 10 is arranged on the shock absorbing mechanism, and the outer edge of the support seat 2 is provided with a downwardly bent installation portion 24, The mounting part 24 is provided with a plurality of threaded holes, and bolts pass through the threaded holes on the mounting part 24 and the vehicle frame to fix the support base 2 on the vehicle frame.

[0077] In the mixer truck with this structure, the fixed seat 3 on it is fixedly connected with the swing part 1, and the speed reducer 10 is arranged on the swing part 1. The pendulum part 1 swings at any angle in the installation groove of the support seat 2 to absorb the vibration and impact force of the mixing tank. The shock-absorbing mechanism has good impact resistance and improves the stability and safety of the mixer truck.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com