Non-corrosive and non-irritant disinfectant as well as preparation method and application thereof

A disinfectant, non-corrosive technology, applied in the chemical field, can solve the problems of high precision equipment, high corrosion, etc., and achieve excellent killing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The following non-corrosive and non-irritating disinfectants are all prepared according to the following preparation method, including the steps:

[0019] Step 1, prepare materials according to the formula;

[0020] Step 2, feeding the materials into the reactor for stirring to obtain a disinfectant.

[0021] As an example, the application of the present invention can quantitatively add the disinfectant to the non-woven non-woven fabric to obtain a disinfectant wet wipe, or it can be sprayed or added to other chemicals, and the application methods can be various, as long as All disinfectants that have utilized the formula of the present invention are within the protection scope of the present invention.

Embodiment 1

[0053] Example 1, 2, the sample 1-3 that 3 obtains acts 0.5min, 1min, 1.5min to E. coli suspension quantitative killing test result as follows table 1-3;

[0054] Example 1 formula: 0.1008% of didecyl dimethyl ammonium chloride, 0.0792% of octyl decyl dimethyl ammonium chloride, 0.072% of dodecyl ammonium chloride with a purity of 99%, and 0.072% of a purity of 99% Fatty alcohol polyoxyethylene ether 0.018%, glycerin with a purity of 99% 1.10%, sodium nitrite with a purity of 99% 0.088%, purified water 98.542%;

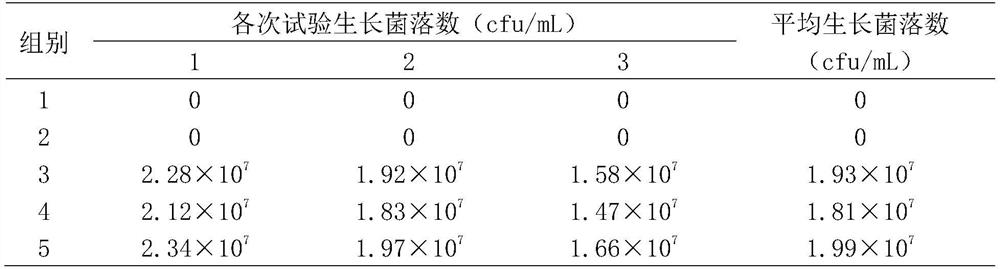

[0055] Table 1 Sample 1 acts on 0.5min, 1min, 1.5min to Escherichia coli suspension quantitative killing test result

[0056]

Embodiment 2

[0057] Example 2 formula: 0.1148% of didecyl dimethyl ammonium chloride, 0.0902% of octyl decyl dimethyl ammonium chloride, 0.079% of dodecyl ammonium chloride with a purity of 99%, and 0.079% of a purity of 99% 0.02% of fatty alcohol polyoxyethylene ether, 1% of glycerin with a purity of 99%, 0.08% of sodium nitrite with a purity of 99%, and 98.616% of purified water;

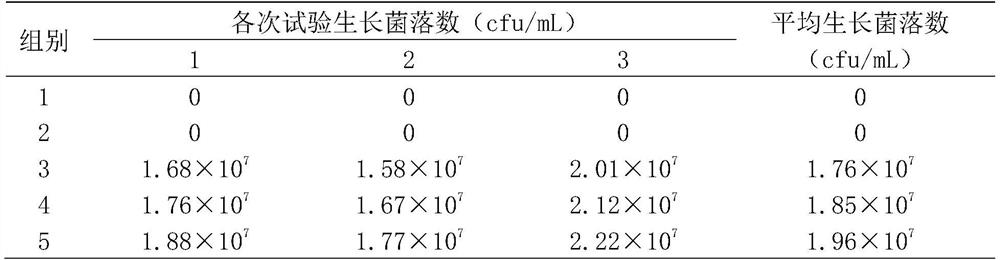

[0058] Table 2 Sample 2 acts on 0.5min, 1min, 1.5min to Escherichia coli suspension quantitative killing test result

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com