Thyristor driving circuit

A technology of thyristor drive and thyristor, which is applied in the field of circuit electronics, can solve the problems of large loss and low efficiency of the drive circuit, and achieve the effects of reducing the area, improving reliability, and reducing the loss of the drive circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

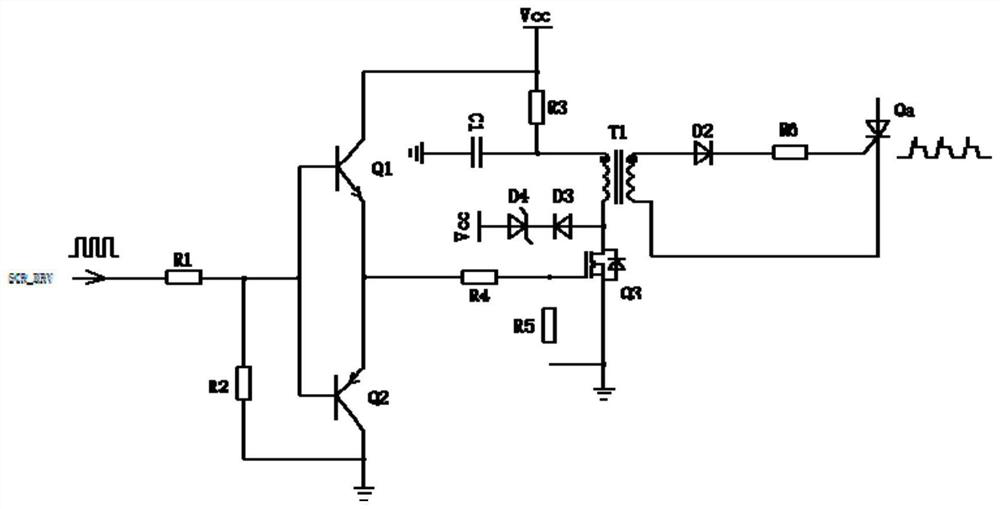

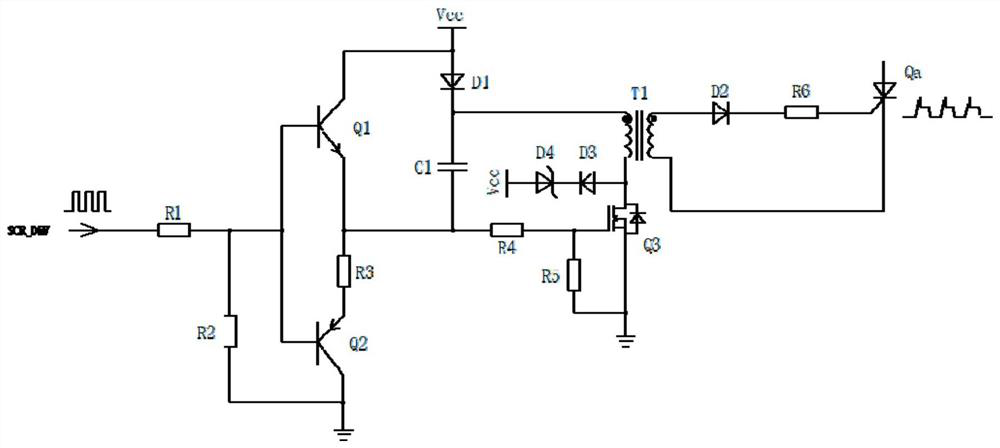

[0030] The present invention provides a thyristor drive circuit, comprising a power supply Vcc, a drive signal input terminal, an auxiliary switch circuit, a main switch circuit, a remagnetic circuit, an energy storage capacitor C1, a diode D1 and a thyristor Qa; the drive signal input terminal is connected to the auxiliary switch circuit , the drive signal input terminal is used to input the drive signal SCR_DRV to control the opening / closing of the auxiliary switch circuit. One terminal node of the energy storage capacitor C1 is divided into two routes, the first route is connected to the power supply Vcc through the diode D1, and the second route is connected to the transformer One end of the primary side of T1 and the other end node of the energy storage capacitor C1 are divided into two paths, the first path is connected to the auxiliary switch circuit, the second path is connected to the other end of the primary side of the transformer T1 through the main switch circuit, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com