A forced ignition type supercritical hydrothermal combustion device

A combustion device and supercritical water technology, applied in the direction of burners, combustion chambers, combustion methods, etc., can solve problems such as ignition failure, enlargement, and blockage of reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

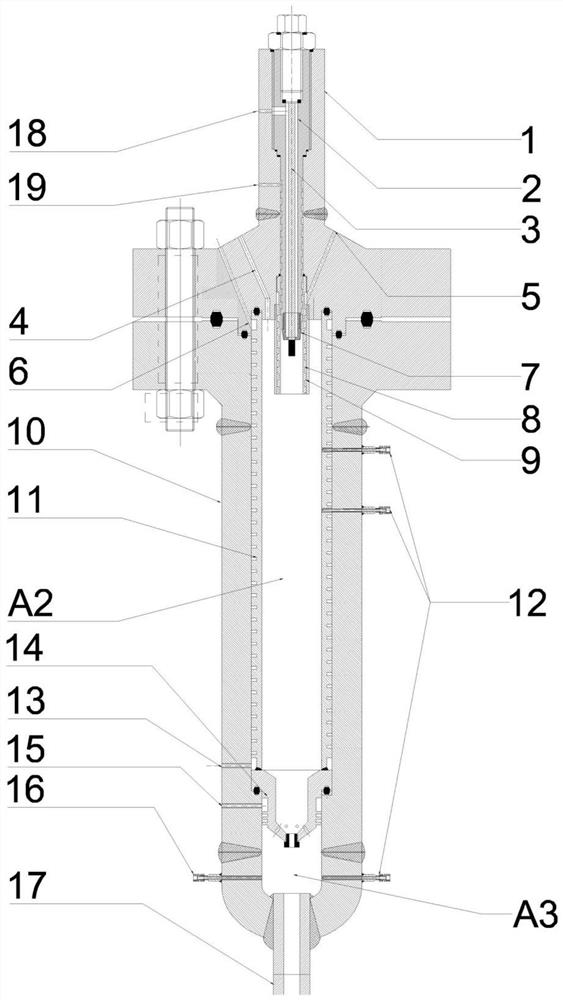

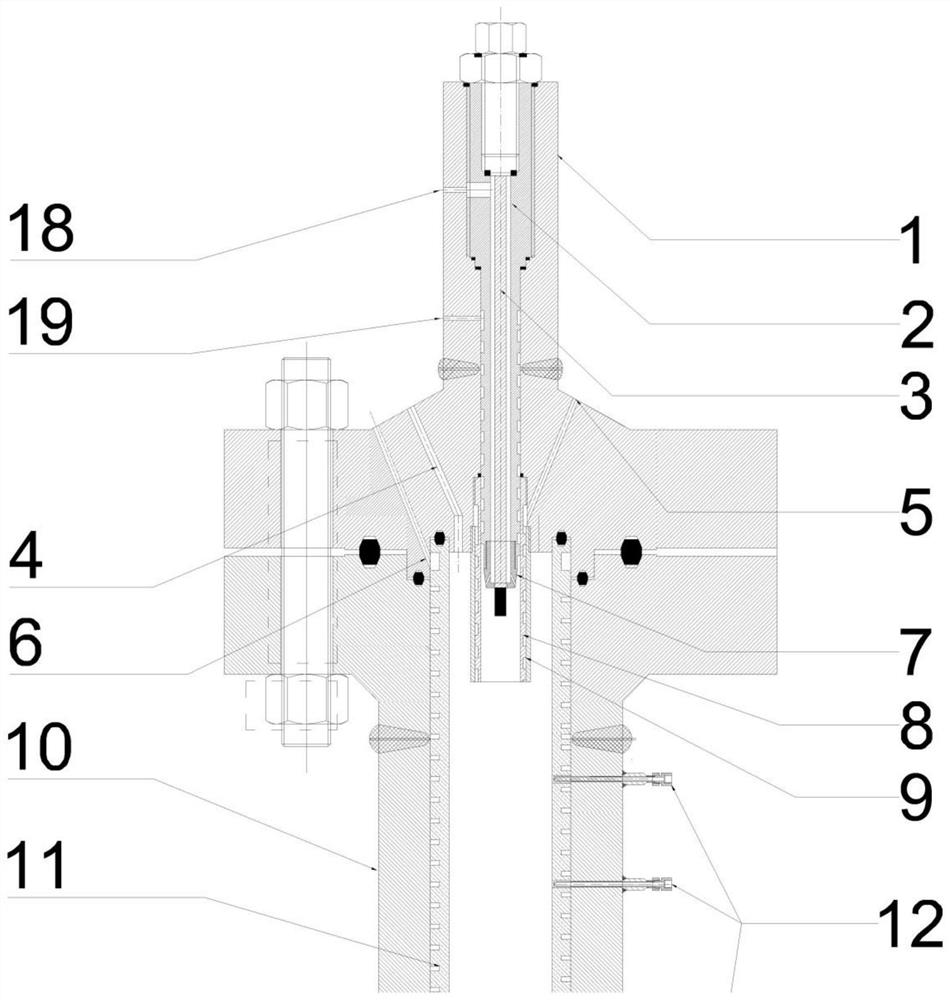

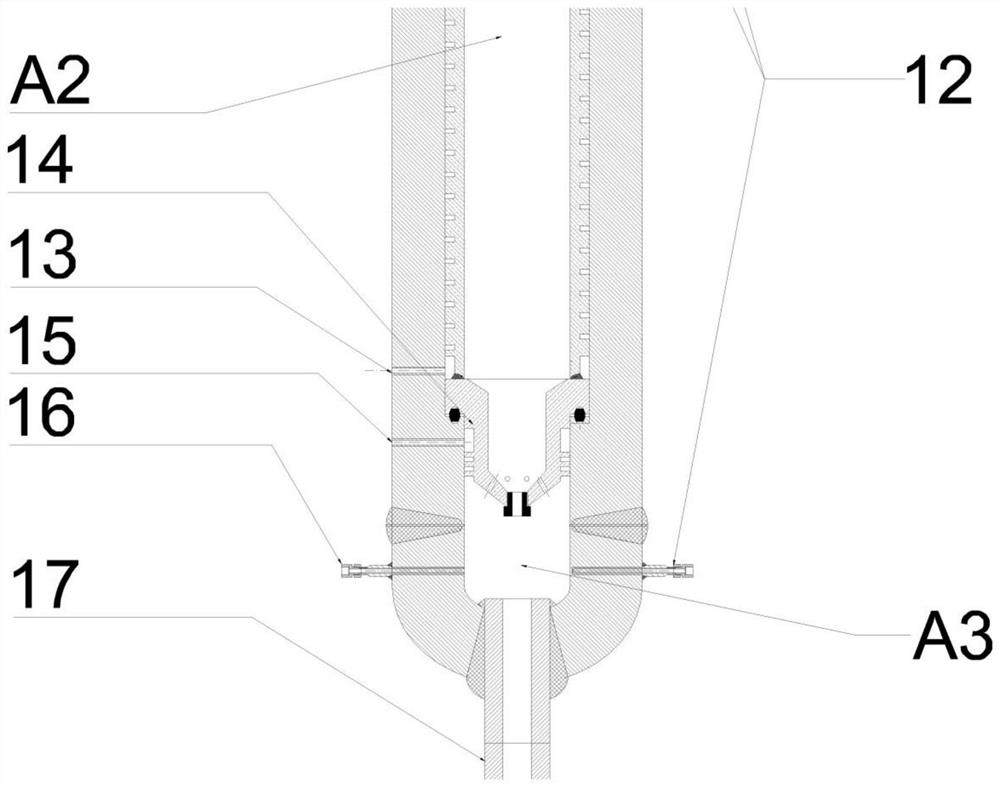

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings and examples.

[0032] like figure 1 , figure 2 and image 3 As shown, the present invention is a forced ignition type supercritical hydrothermal combustion device, comprising a main casing 10, and a top end cover 1 is installed on the top of the main casing 10.

[0033] In one embodiment, the main body shell 10 has a cylindrical shape, but those skilled in the art can understand that its shape is not limited to a cylindrical shape, and can also be other shapes that are convenient for industrial realization.

[0034] In one embodiment, the top end cover 1 is mounted on the main body casing 10 through a bolt group, and a high temperature resistant sealing ring can be provided on the contact surface.

[0035] In the present invention, a dividing block 14 is installed inside the main body casing 10, and the dividing block 14 divides the interior of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com