Assembly type building safety monitoring device

A safety monitoring and assembly technology, which is applied in the direction of TV, supporting machines, supporting structures of photovoltaic modules, etc., can solve the problems affecting the monitoring of the construction site, the angle of the monitoring device, the inconvenient adjustment of the height, and the poor flexibility of the monitoring device, so as to improve the collection The effect of lighting, improving the power supply life time, improving the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

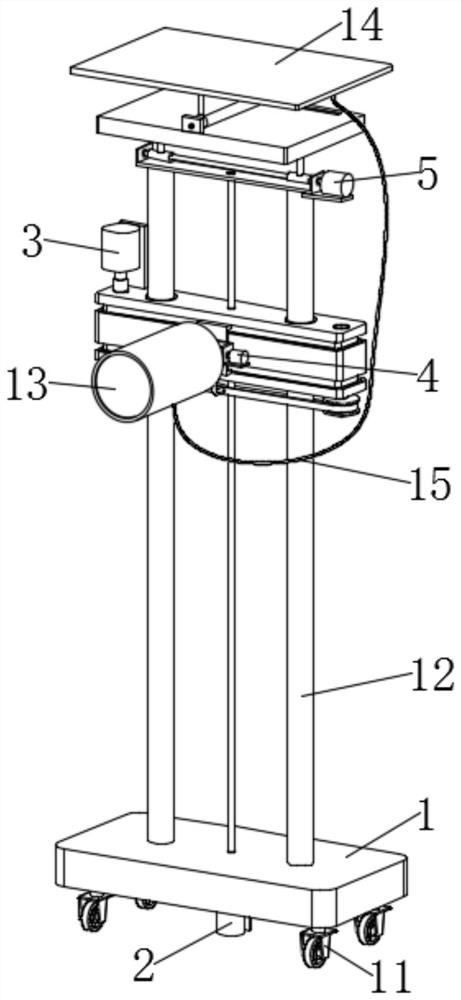

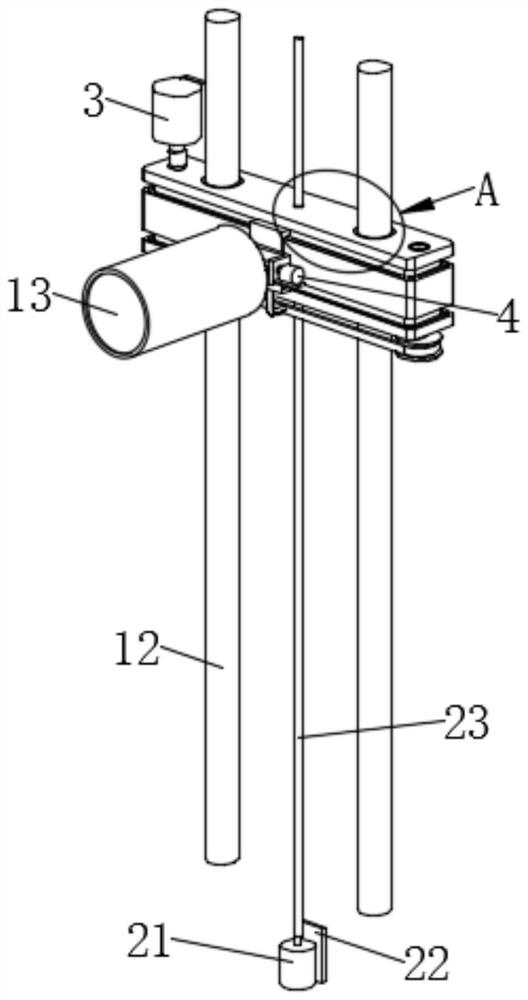

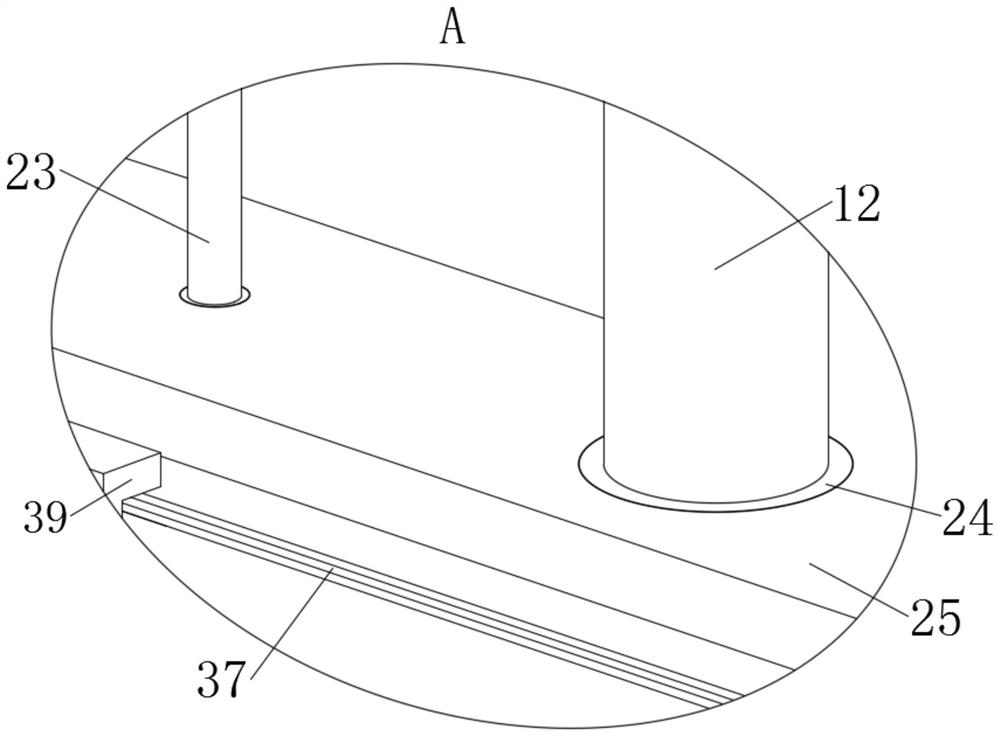

[0033] Example: such as Figure 1-11 As shown, the present invention provides a prefabricated building safety monitoring device, which includes a mobile chassis 1, a monitoring body 13 and a solar panel body 14. The upper surface of the mobile chassis 1 is symmetrically fixed with a sliding rod 12, and between the two sliding rods 12 There is a lifting mechanism 2 between them, and the lifting mechanism 2 can easily realize the height adjustment of the monitoring body 13. The surface of the lifting mechanism 2 is provided with a rotating mechanism 3, which can easily realize the horizontal position rotation of the monitoring body 13. The rotating mechanism 3 The surface of the surface is provided with a monitoring and adjusting mechanism 4, which can easily realize the vertical angle adjustment of the monitoring body 13, and the end of the two sliding rods 12 away from the mobile chassis 1 is provided with a solar panel adjusting mechanism 5, and the solar panel adjusting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com