Dust removal equipment for textile processing

A kind of dust removal equipment and textile dust technology, applied in the field of textile processing, can solve the problems of affecting the quality of textile fabrics, single dust removal method, incomplete dust removal, etc., achieve stable dust removal effect, good dust removal effect, and avoid clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

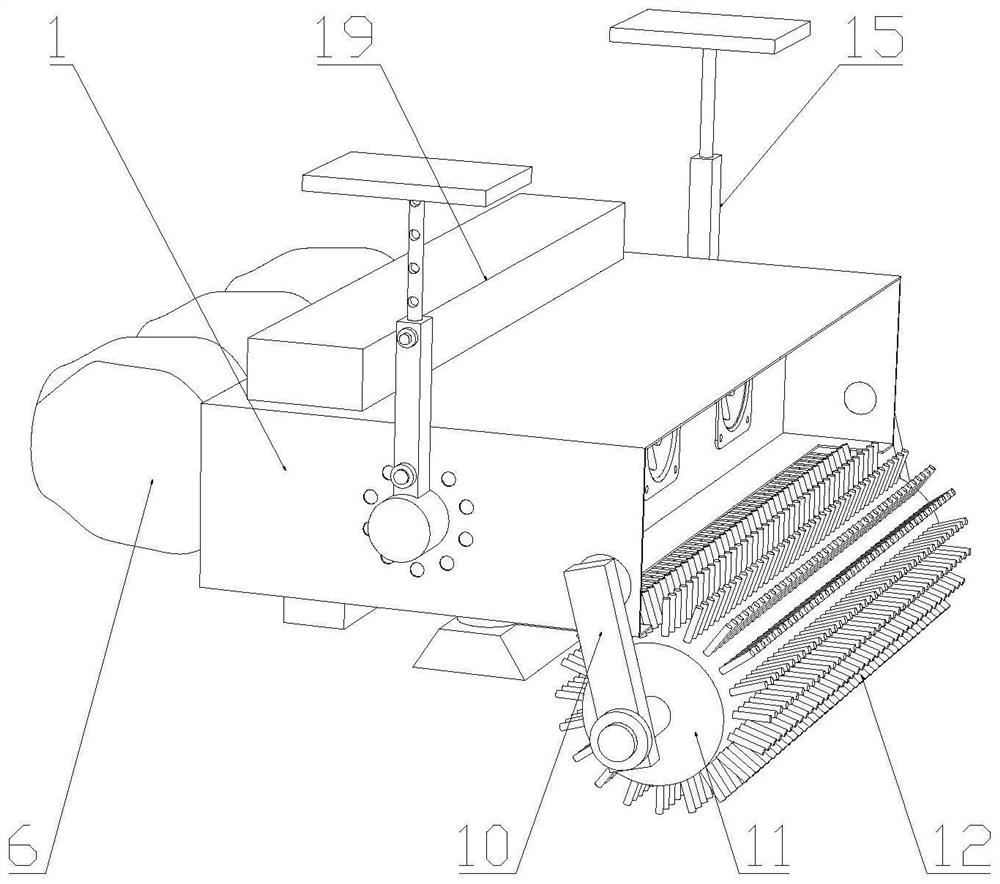

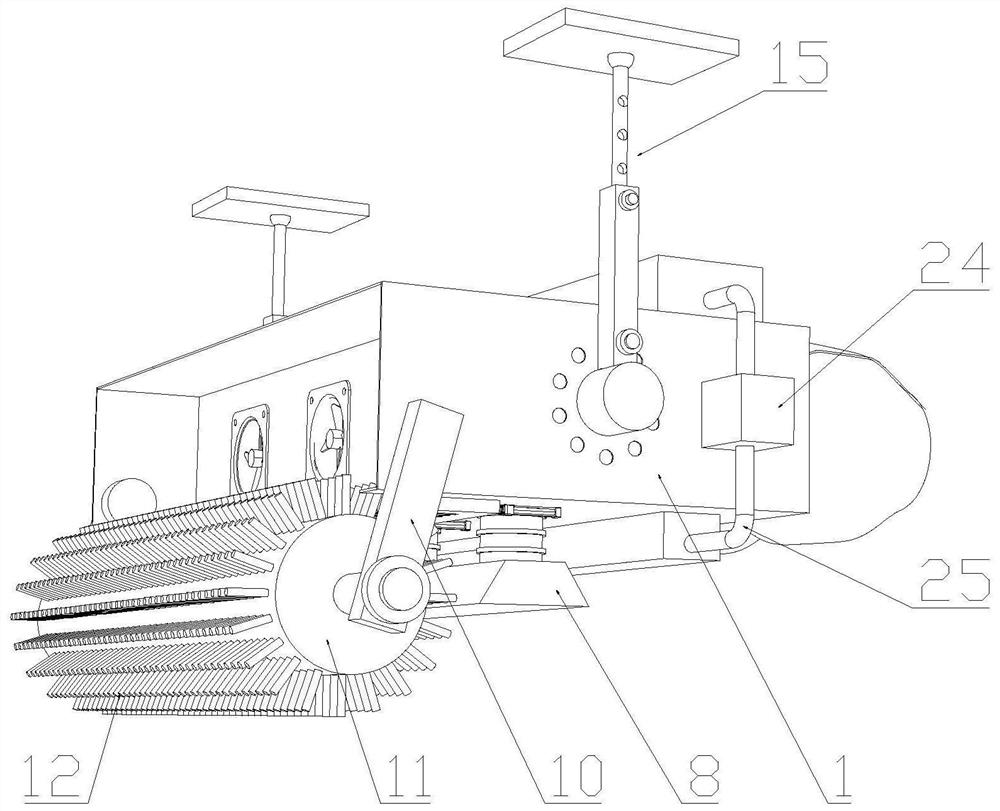

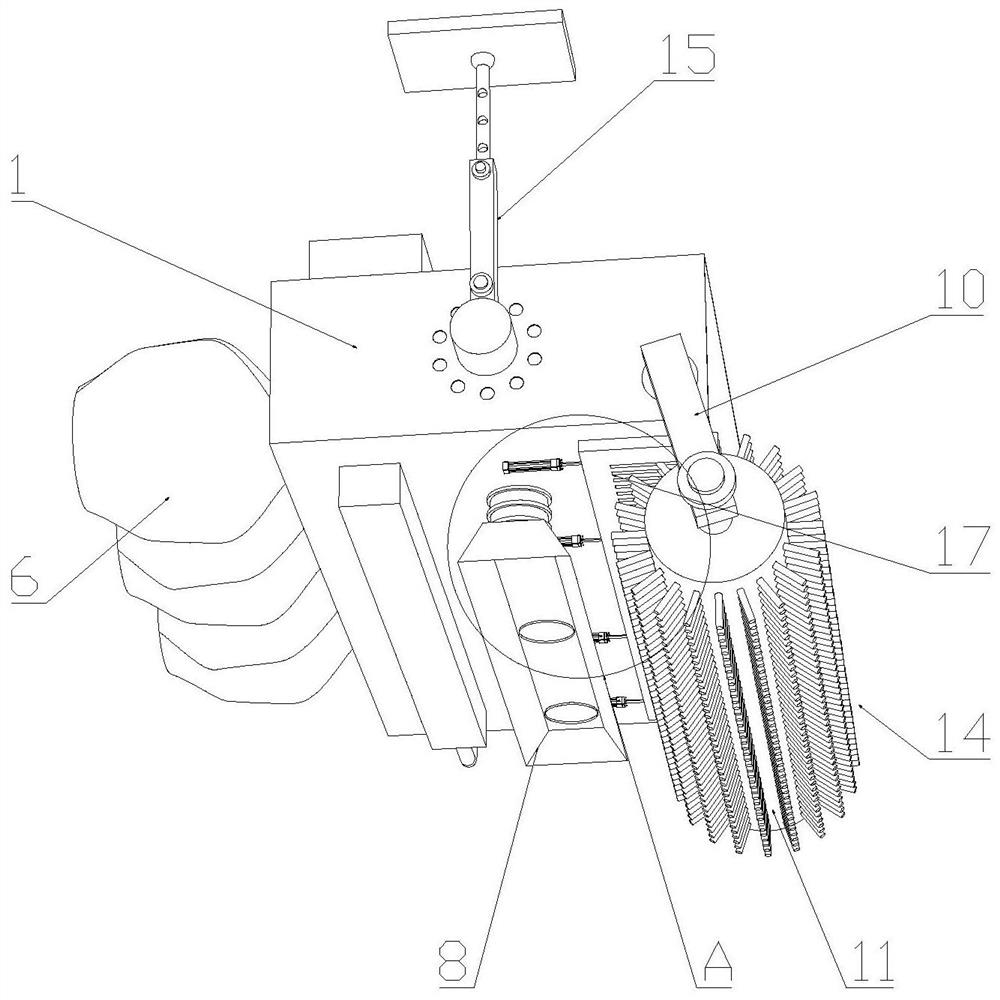

[0032] Such as Figure 1-5 As shown, a kind of dust removal equipment for textile processing proposed by the present invention includes a dust removal box 1, a mounting frame 2, a dust suction fan one 3, a filter plate 4, a dust suction fan two 5, a dust collection bag 6, a dust suction pipe 7, Dust collecting cover 8, dust removal assembly and controller; the dust inlet end opening of dust removal box 1; installation frame 2 and filter plate 4 are arranged in the inside of dust removal box 1 successively along the dust removal direction, and its internal space is divided into dust removal chamber 33 and The filter chamber 34; the installation frame 2 is provided with two groups; the dust suction fan one 3 is arranged on the dust inlet end in the dust removal box 1 through the installation frame 2; the dust suction fan two 5 is arranged on the dust outlet end of the dust removal box 1 of the filter plate 4 Above; the dust collection bag 6 is connected to the dust outlet end of...

Embodiment 2

[0035] Such as Figure 6 As shown, on the basis of the above-mentioned embodiments, the upper end of the dust removal box 1 in the present embodiment is provided with a cleaning assembly; On the upper end of the dust removal box 1; multiple groups of nozzles 20 are arranged, and the multiple groups of nozzles 20 are respectively located on both sides of the filter plate 4, and are all communicated with the liquid storage tank 19, and the nozzles 20 at the dust inlet end of the filter plate 4 spray liquid toward the filter plate 4. The spraying direction of the nozzle 20 located at the dust outlet end of the filter plate 4 is towards the liquid collection channel 21 downward; the bottom of the dust removal box 1 is provided with a liquid collection channel 21; the liquid collection bucket 22 corresponds to the position of the liquid collection channel 21 and is set The bottom of the dust removal box 1; the filter screen 23 is arranged in the liquid collecting bucket 22. The cl...

Embodiment 3

[0038] Such as Figure 7As shown, on the basis of the above-mentioned embodiments, the dust removal box 1 in this embodiment is provided with a mounting assembly 15; the mounting assembly 15 includes a connecting seat 26, a mounting rod 28, a telescopic rod 29 and a mounting plate 32; the connecting seat 26 is rotated and set On the dust removal box 1 ; one end of the installation rod 28 is connected with the connection seat 26 , and the other end is slidably connected with the telescopic rod 29 ; Mounting assembly 15 also comprises threaded rod one 27 and nut one; Dust removal box 1 is provided with a circle of fixing hole one 13 along the periphery of connection seat 26; One end of mounting rod 28 is provided with threaded groove one; Through slot 1 is threadedly matched with mounting rod 28, and snapped into fixed hole 1 13 of corresponding position, and the other end cooperates with nut 1. Mounting assembly 15 also comprises threaded rod two 30 and nut two; The other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com