Oil-water separation and purification device for catering and purification method of oil-water separation and purification device

A technology for purification device and drinking oil, applied in separation method, chemical instrument and method, grease/oily substance/float removal device, etc., can solve the problem of grease and residue removal in incapable catering wastewater, and prevent incomplete separation , Protect the water environment, good oil-water separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

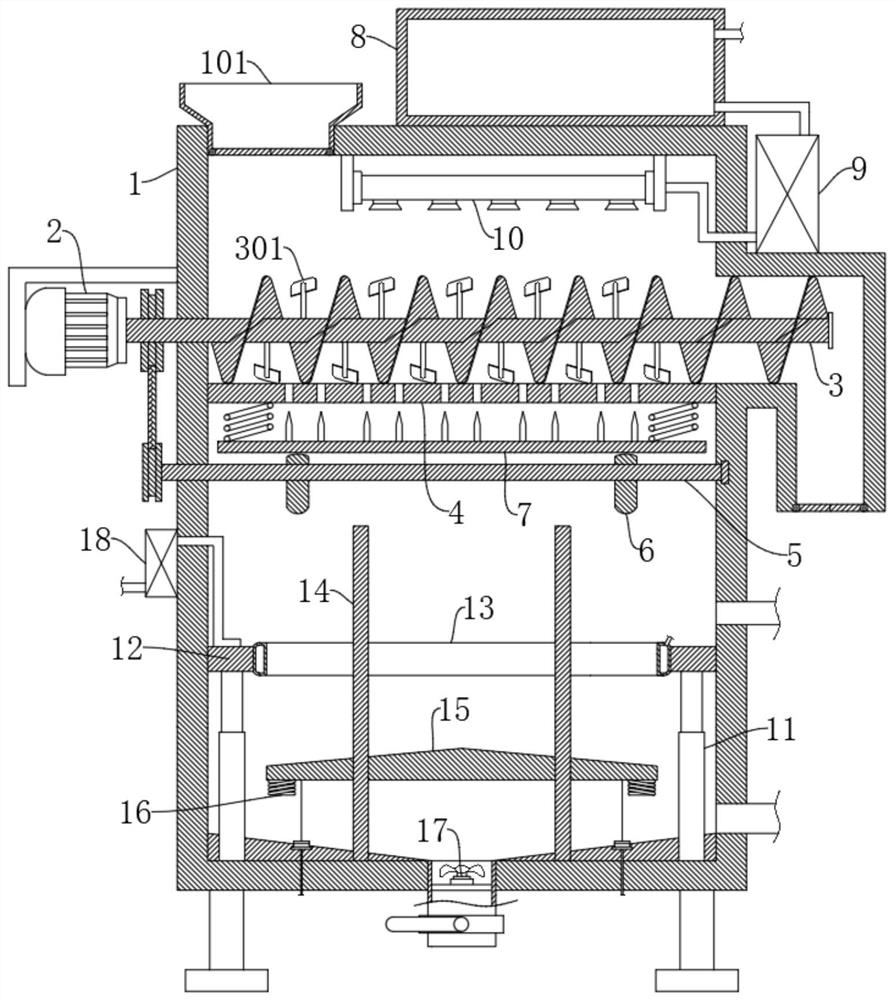

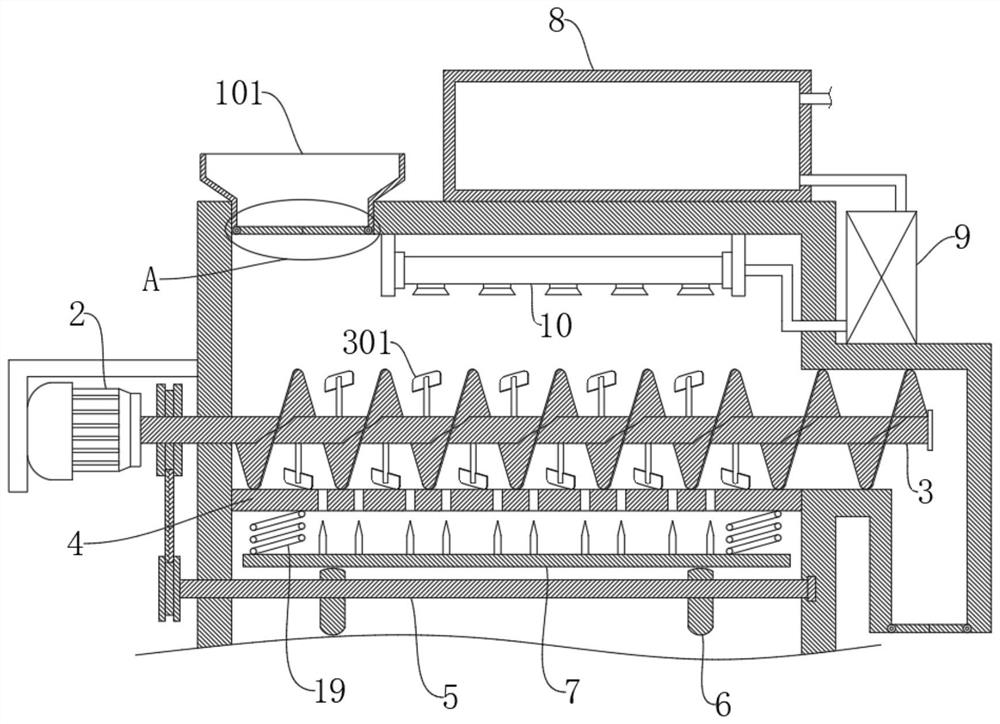

[0035] refer to Figure 1-7 , an oil-water separation and purification device for catering, including a box body 1, and also includes: a filter plate 4 installed in the box body 1; a motor 2 installed on the side of the box body 1 away from the slag discharge port through a bracket; a screw propeller 3. It is rotatably connected to the filter plate 4, and the end away from the slag outlet of the box body 1 is fixedly connected to the output end of the motor 2; the waterproof telescopic rod 11 is installed on both sides of the lower end of the box body 1; the moving plate 12, The sealing sliding connection is in the box body 1, and the lower end is fixedly connected with the telescopic end of the waterproof telescopic rod 11, wherein the moving plate 12 is provided with an annular through opening; the annular airbag 13 is sealed and fixedly connected to the annular through opening; the limit rod 14, fixedly connected to the inner lower end of the box body 1, the separation plat...

Embodiment 2

[0038] refer to Figure 1-3 , a kind of oil-water separation and purification device for catering, which is basically the same as Embodiment 1, furthermore: the lower end of the filter plate 4 is fixedly connected with a dredging tooth plate 7 through a telescopic spring 19, and the rack on the dredging tooth plate 7 is connected to the filter plate The positions of the filter holes on 4 correspond to each other. The lower end of the box body 1 close to the dredging tooth plate 7 is connected to the rotating rod 5 by rotation. 3 The side close to the motor 2 is fixedly connected with the first runner, and the end of the turning rod 5 close to the motor 2 runs through the box body 1, and is fixedly connected with the second runner, and the first runner and the second runner are connected by a belt , when the screw propeller 3 rotates, it can drive the first runner to rotate, the first runner drives the second runner to rotate through the belt, the second runner drives the rotat...

Embodiment 3

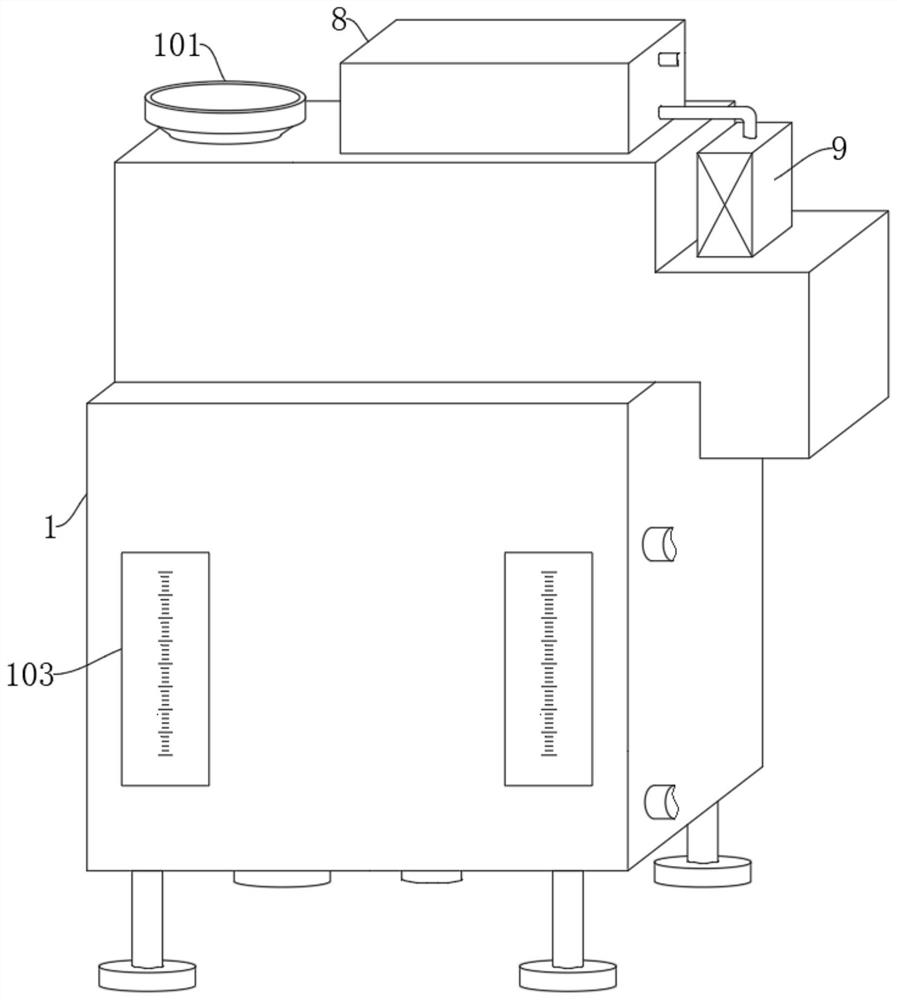

[0042] refer to image 3 and Figure 5 , a kind of oil-water separation and purification device for catering, which is basically the same as embodiment 1, and further is: the feed inlet of the casing 1 is fixedly connected with a feed funnel 101, and the feed funnel 101 and the slagging outlet of the casing 1 All are connected with sealing plate 22 by torsion spring rotation, through the setting of sealing plate 22 and torsion spring, when the device is not working, sealing plate 22 can discharge the slag of feed funnel 101 and box body 1 under the action of torsion spring. The mouth is sealed to prevent the peculiar smell in the box body 1 from floating out, which will affect the environment and workers, and effectively improve the environmental protection of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com